Solar cell having double-sided micro/nano composite structure and preparation method thereof

A micro-nano composite structure and solar cell technology, which is applied in circuits, nanotechnology, photovoltaic power generation, etc., can solve problems such as narrow absorption spectrum range, inability to effectively absorb and convert sunlight, and low efficiency of solar cells, and achieve high conversion efficiency , the effect of high open circuit voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

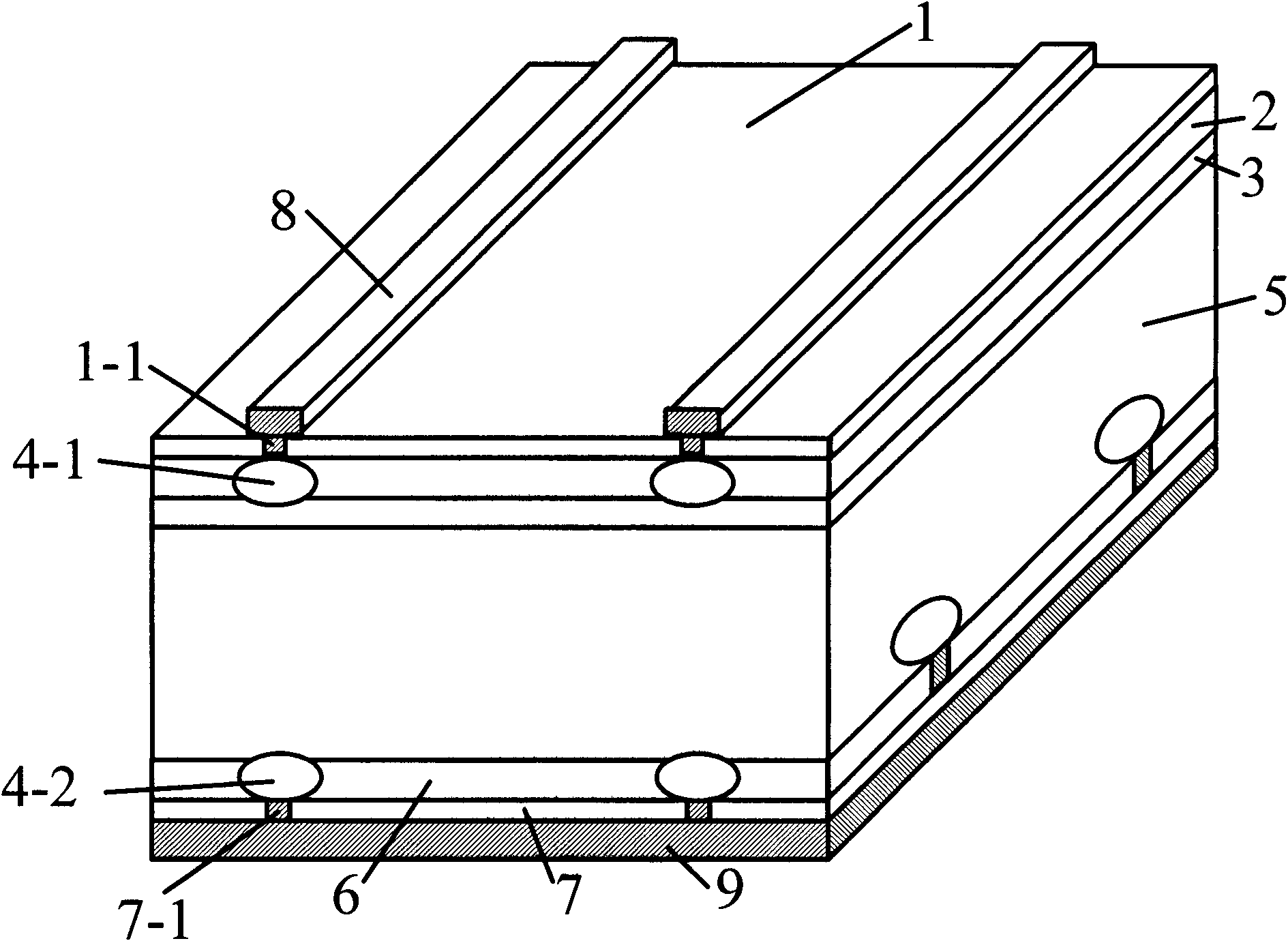

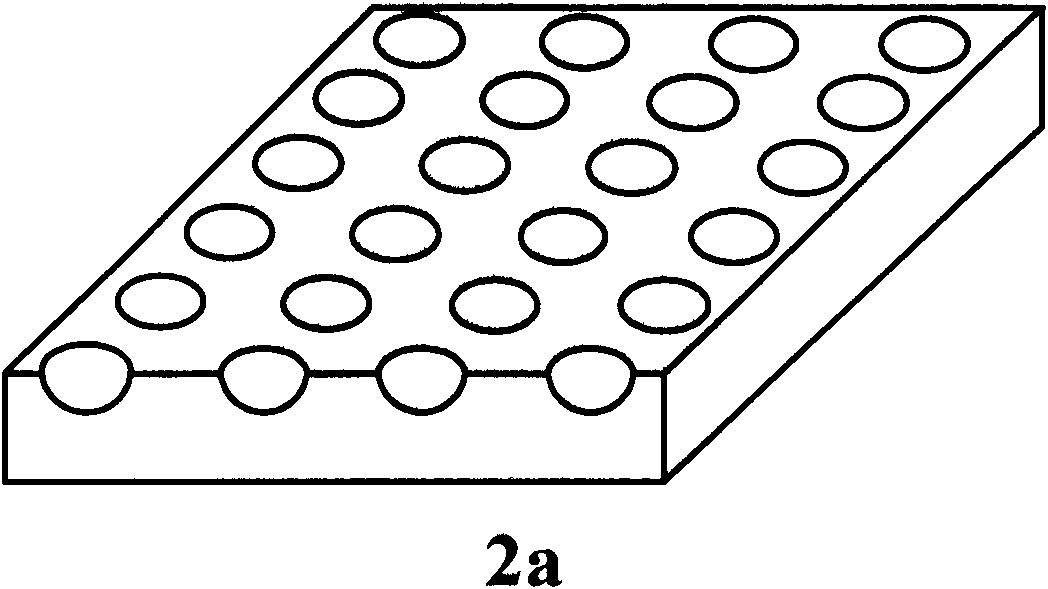

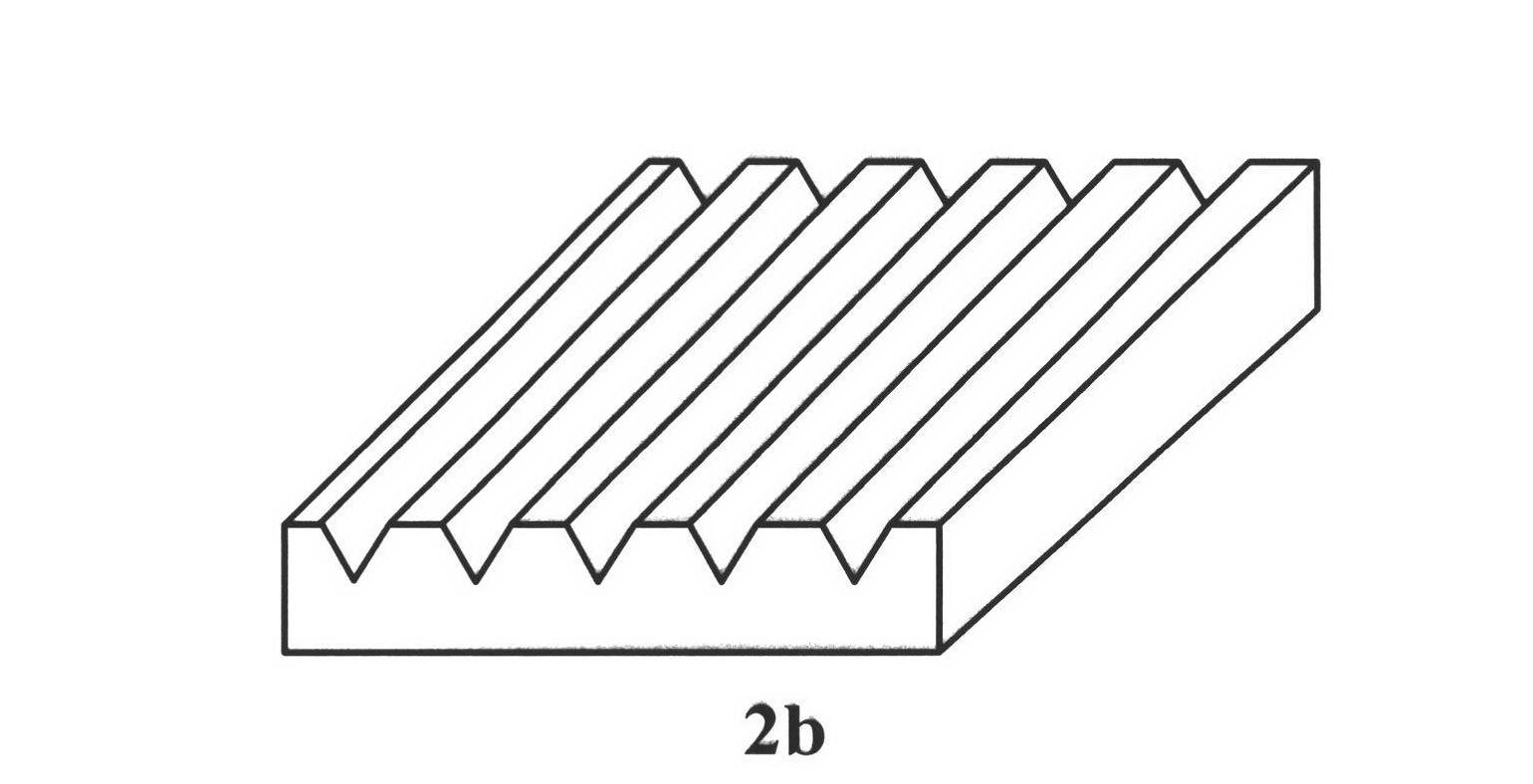

[0019] refer to figure 1 , figure 1 It is the solar cell structure of the double-sided micro-nano composite structure of the present invention. The figure includes: front nanoscale black silicon anti-reflection layer 1, front anti-reflection layer through hole 1-1, front micron-scale light absorbing layer 2, doped diffusion layer 3, front heavily doped diffusion area 4-1, back heavily doped Miscellaneous diffusion region 4-2, silicon-based substrate 5, micron-scale light-absorbing layer 6 on the back, nano-scale black silicon anti-reflection layer 7 on the back, through-hole 7-1 on the back anti-reflection layer, front gate electrode 8, metal layer on the back reflective electrode 9.

[0020]Among them, the front nanoscale blac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com