Assembly Technology of Double-groove Top Roller Bearings in the Outer Ring of Textile Machinery

A technology of bearing assembly and double grooves, which is applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of short service life of bearings, easy wear of inner holes of bearing outer rings, unstable yarn quality, etc., and achieve long-lasting Stabilize the quality of yarn, solve the effect of short bearing life and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in detail again in conjunction with above-mentioned accompanying drawing embodiment:

[0021] The assembly process of the double-groove top roller bearing on the outer ring of the textile machine is as follows:

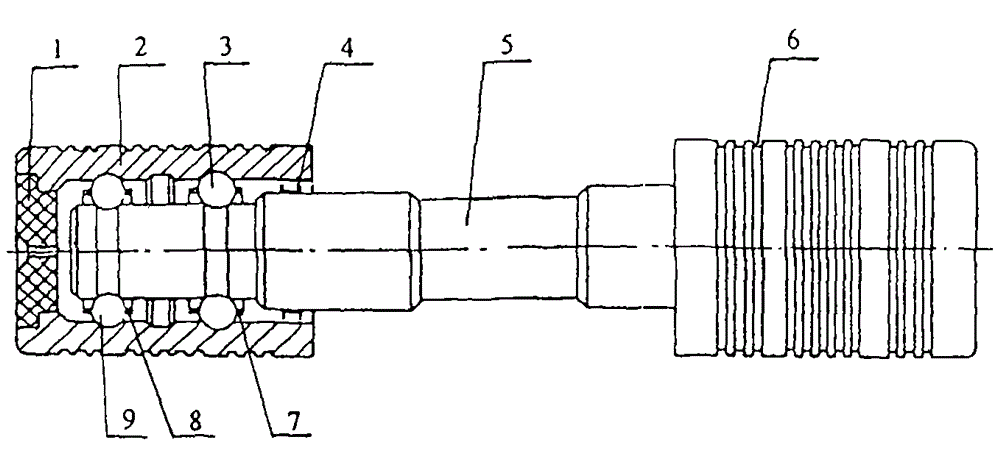

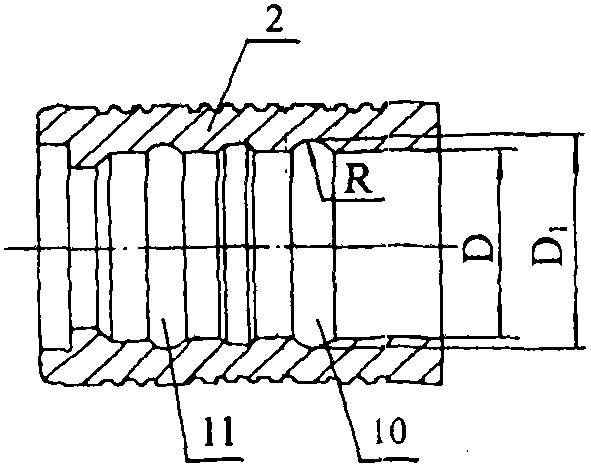

[0022] 1. Press figure 1 Prepare the following parts to be installed: mandrel 5, bearing outer ring 2, bearing cage (including front cage 8 and rear cage 7), steel balls (including front row steel balls 9 and rear row steel balls 3), " "I" type dustproof ring 4. Among them, the diameter of the steel ball has been graded by the steel ball factory according to 0.0015 mm before entering the factory, and the R circular groove of the mandrel, the R circular groove of the bearing outer ring and the steel ball size are selected and matched. The end cover 1 and the rubber sleeve (not shown in the figure) used for end sealing are assembled by the textile factory, because lubricating oil needs to be injected into the inner cavity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com