Device and method based on magnetic field force for realizing peg-in-hole assembly

A magnetic field force, shaft hole technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of assembly failure, uncontrollable contact force, workpiece damage, etc., to avoid damage, improve assembly quality and work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

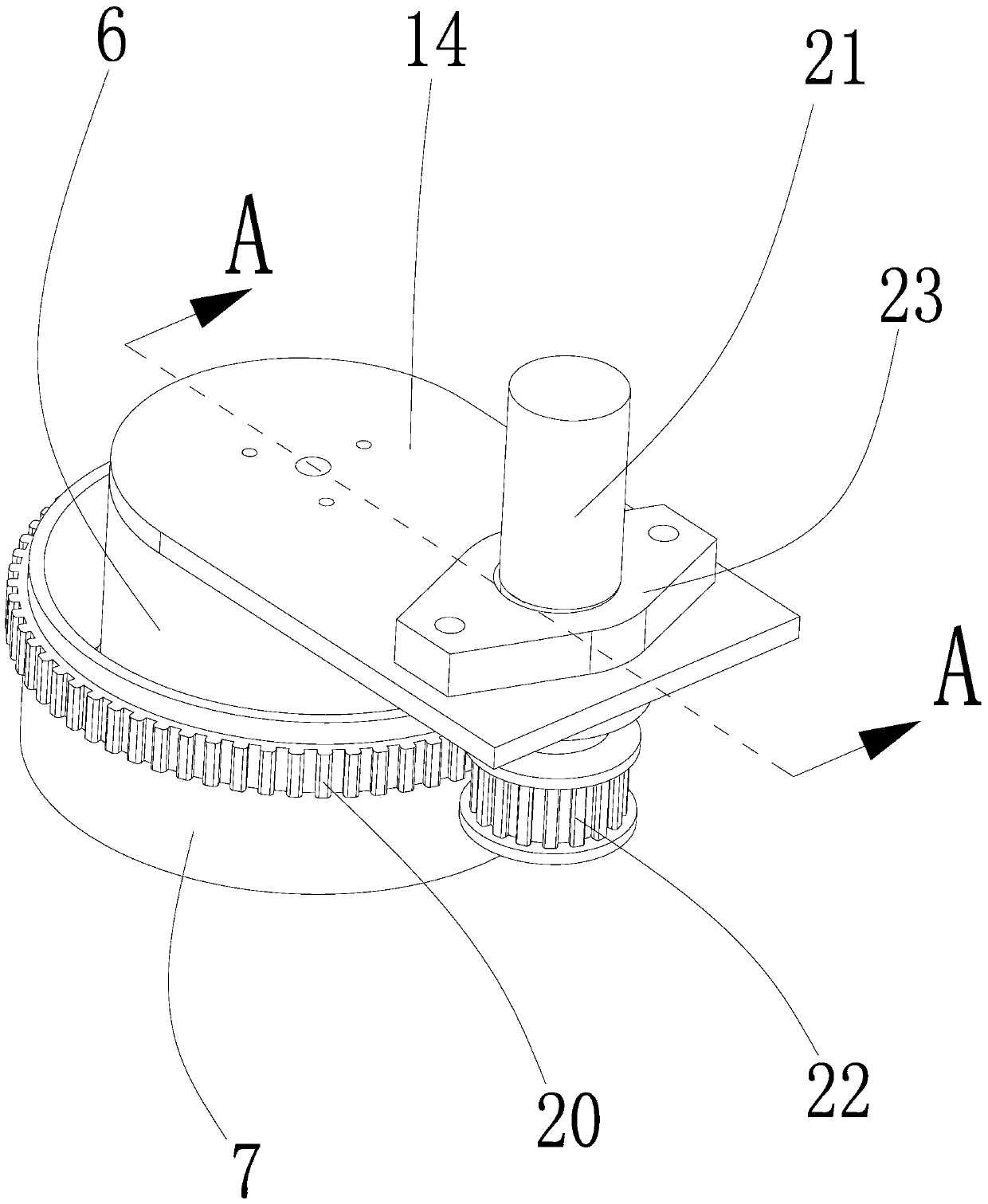

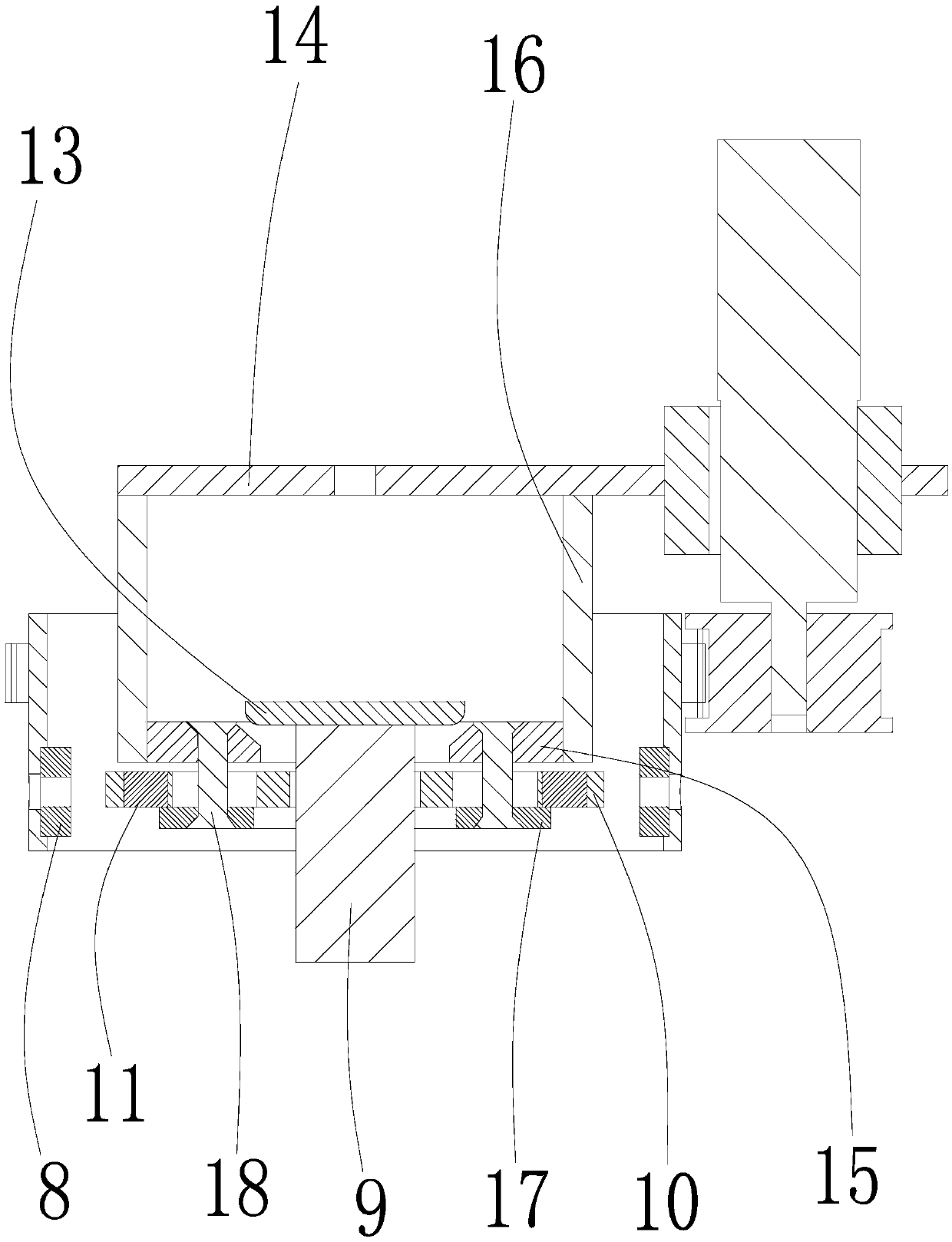

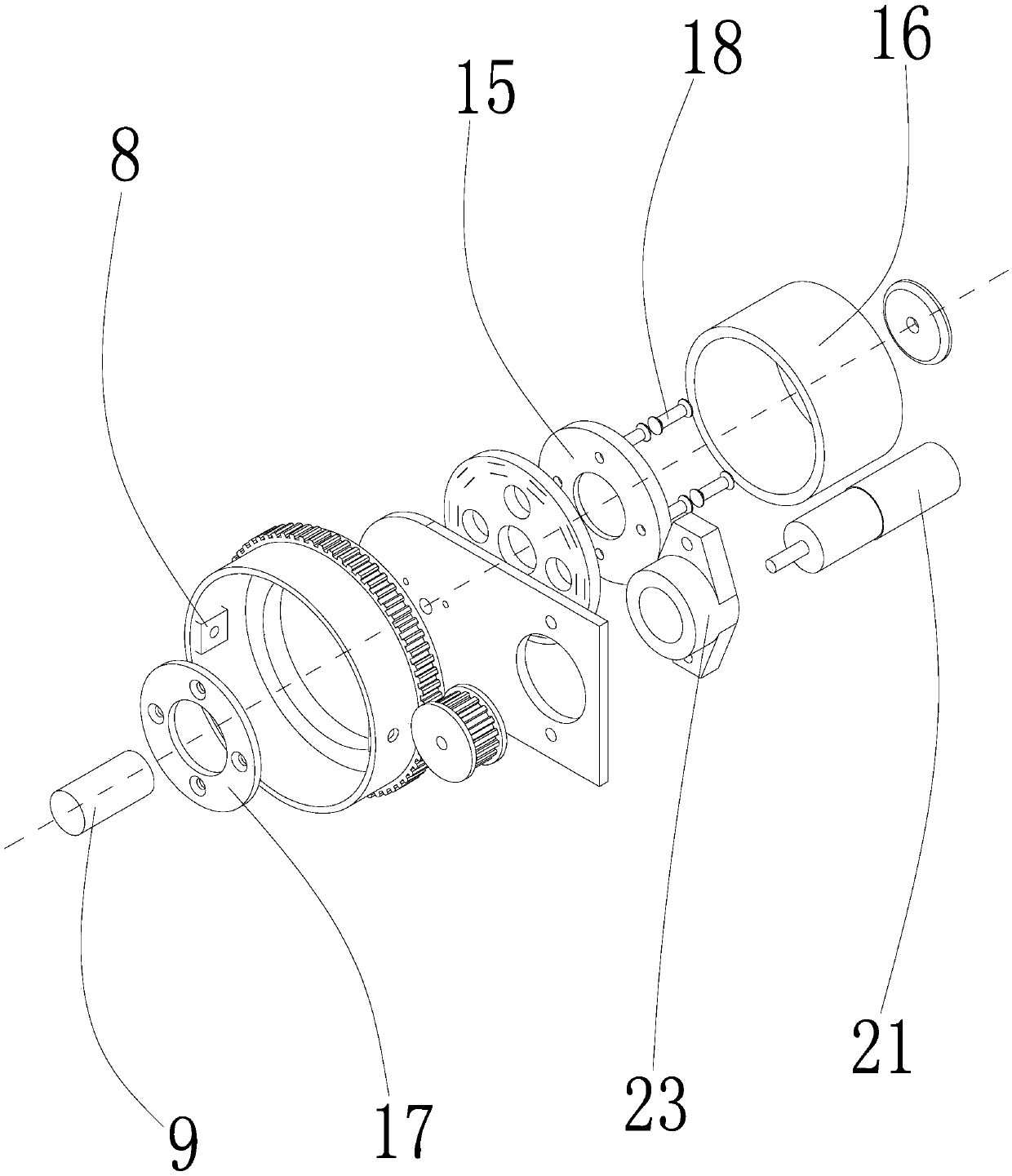

[0022] Please see attached figure 1 , attached figure 2 And attached Figure 4 , a device for shaft hole assembly based on magnetic field force, including a housing 6 and a rotating sleeve 7 sleeved outside the housing 6 to rotate, and the inner wall of the rotating sleeve 7 is provided with magnets 8 on opposite sides , the housing 6 is provided with an end connector 9 that can at least be connected to the assembly shaft, and a magnet frame 10 is arranged below the housing 6 and opposite to the magnet 8, and each magnet frame 10 is A plurality of pairs of magnets 11 are arranged, and the end connector 9 passes through the bottom of the housing 6 from the housing 6 and extends through the magnet frame 10 from the bottom of the magnet frame 10, and the magnet frame 10 can move back and forth radially, When the rotating sleeve 7 rotates, the magnet 8 will generate an attractive or repulsive force on the magnet 11 on the magnet frame 10, so that the magnet frame 10 moves back ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com