Hydraulic lifting inverted construction method for steel inner cylinder of chimney in thermal power plant

A thermal power plant, hydraulic lifting technology, applied in the direction of building types, buildings, towers, etc., can solve the problems of high control difficulty such as pressure uniformity, difficulty in synchronous coordination of winch traction, high cost of construction equipment, etc., and achieve simple load transfer mode , facilitate observation and inspection, and reduce construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The construction method steps of the chimney steel inner tube of the thermal power plant are as follows:

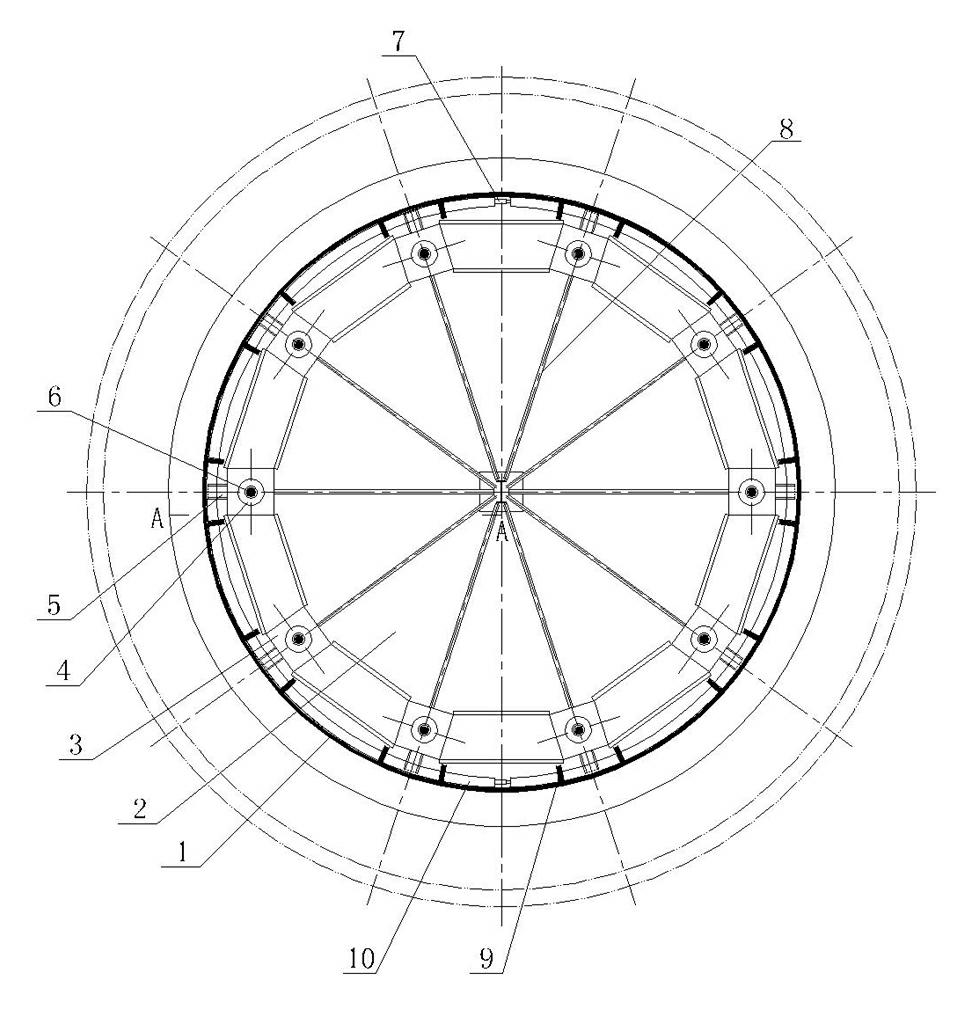

[0026] 1. Divide the chimney steel inner cylinder 1 along its height direction into multiple cylinder sections 101 of equal height, and each cylinder section 101 is divided into multiple cylinder pieces of equal size according to the size requirements for the convenience of coiling.

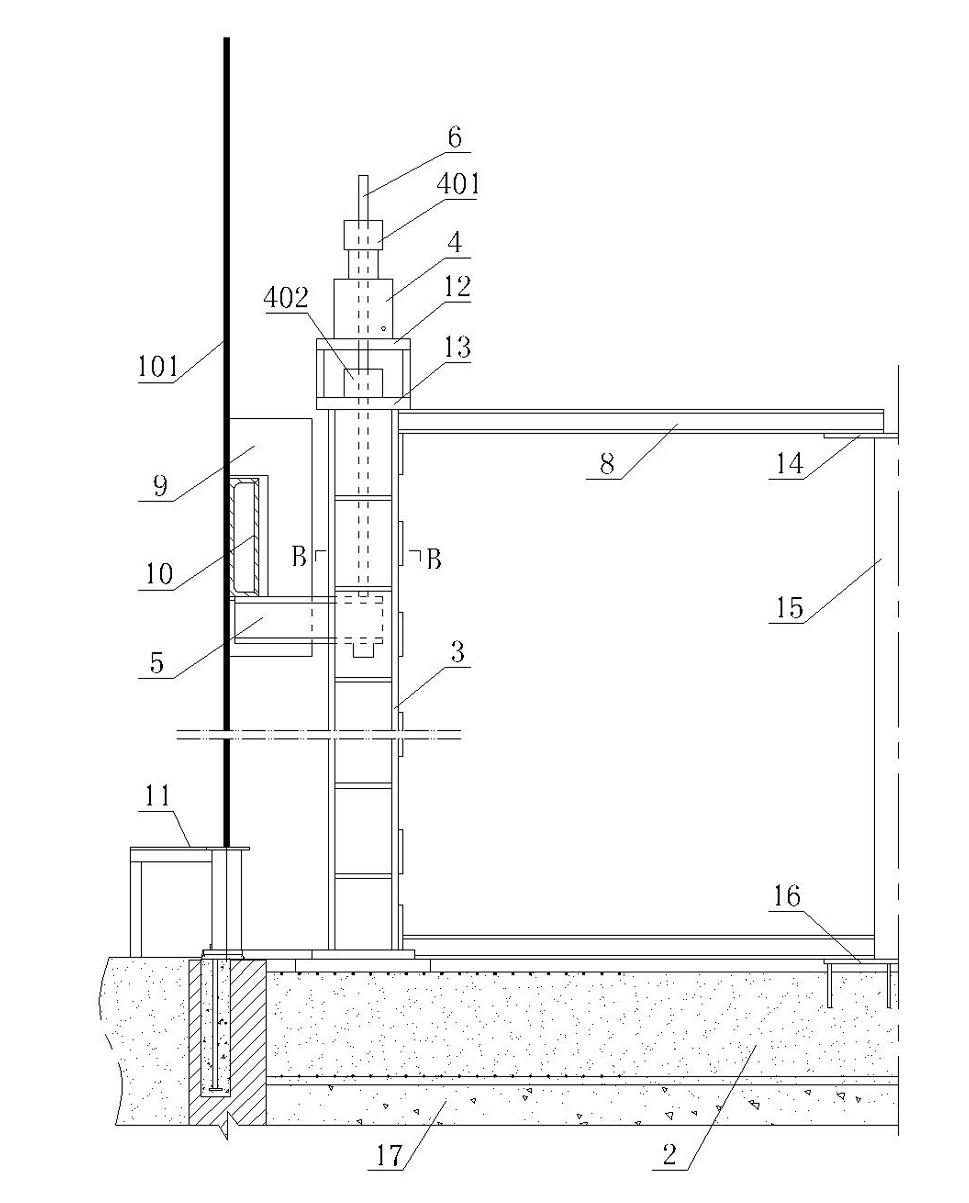

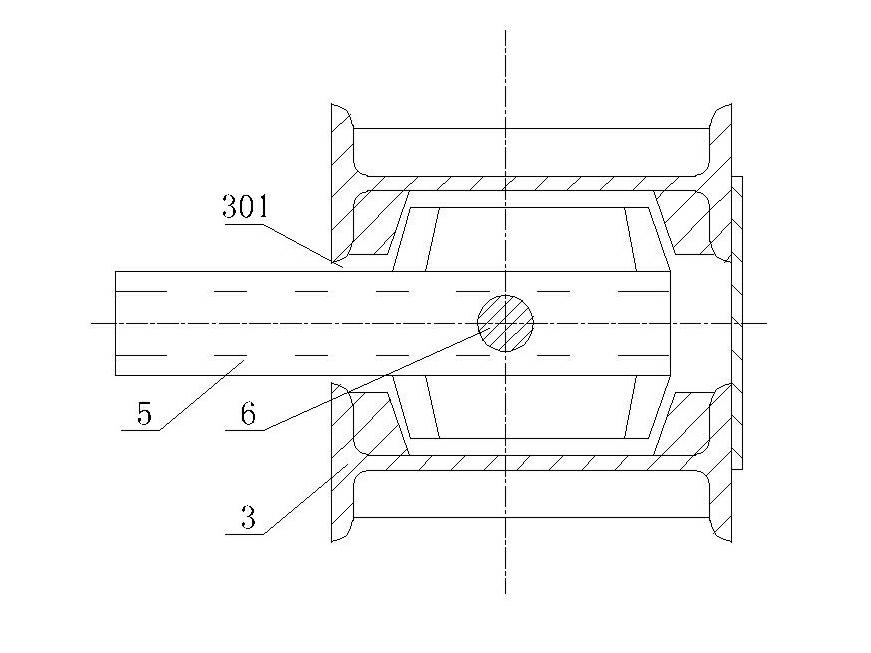

[0027] 2. If figure 1 — image 3 As shown, first, the jack support foundation 2 is made on the foundation 17 in the predetermined installation position of the chimney steel inner cylinder 1. The jack support foundation 2 is cast into a cylindrical shape with concrete, and its diameter and depth need to pass through the basic bending, shearing, and anti-corrosion tests. For punching and bearing capacity checking, the upper and lower layers of steel bars are set in the jack bracket foundation 2 and the metal embedded part 16 is arranged in the center of the upper surface, and the hydra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com