'Outside-cylinder series-connection type' non-condensable gas removing device in low-temperature multi-effect distillation seawater desalination system

A technology for removing devices and condensing gas, which is applied in the field of non-condensing gas removing devices, can solve the problems of limiting the improvement of the overall performance of the system and the range of operation adjustment, inconvenient adjustment or replacement, etc., so as to improve the scope of adaptation and facilitate the change of operating conditions , The effect of improving the performance of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will now be described in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited thereto.

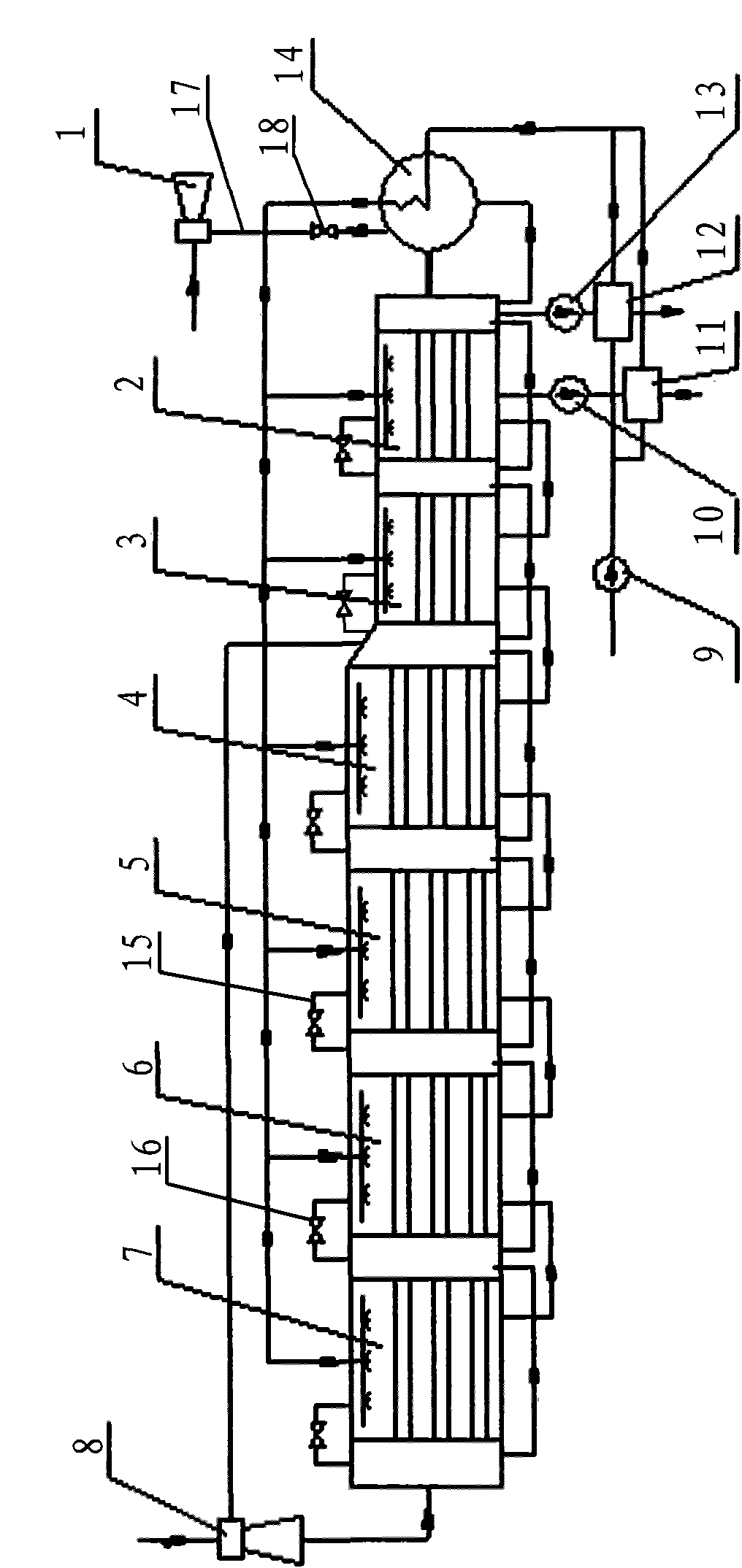

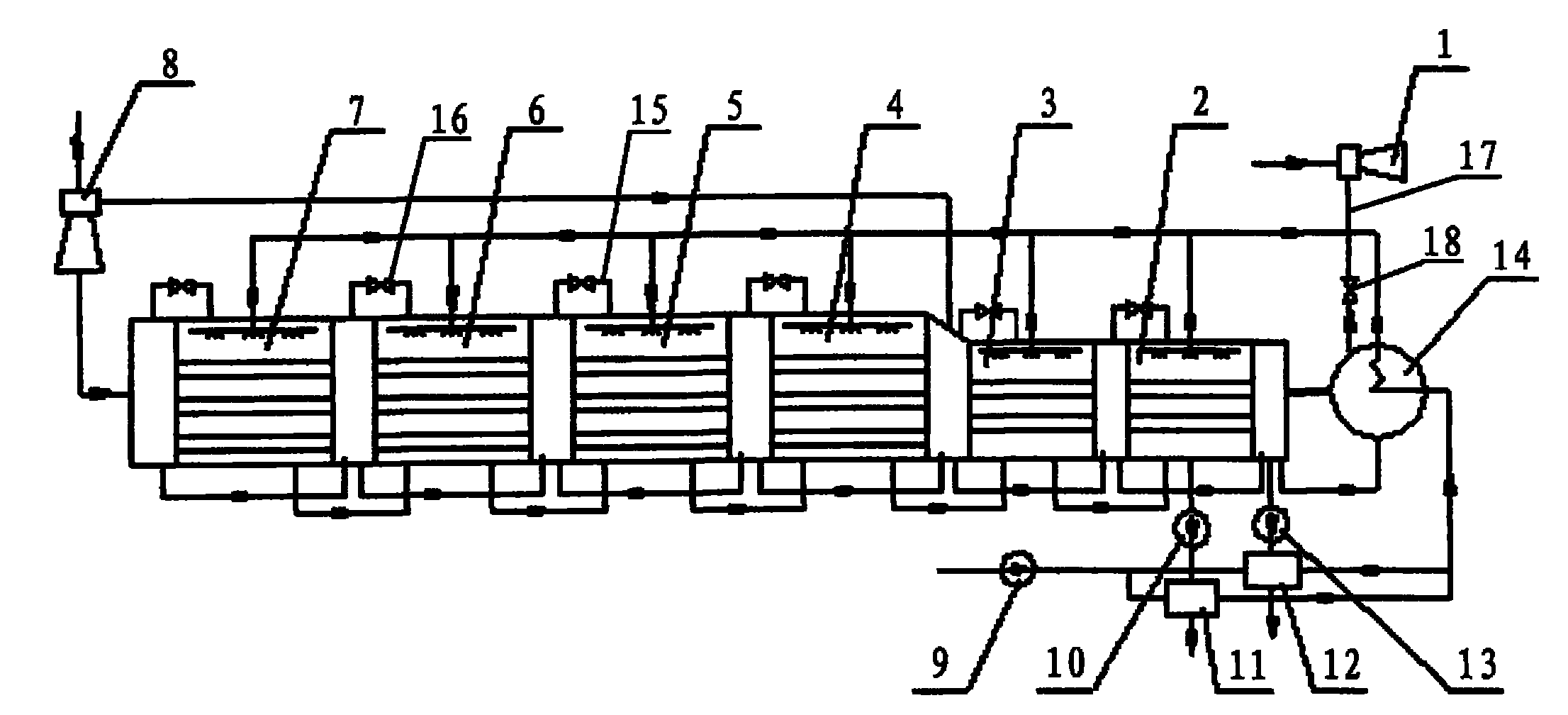

[0018] Low-temperature multi-effect seawater desalination system, including 6-effect evaporator 2-7, steam ejector 8, condenser 14, non-condensable gas removal device, concentrated brine heat exchanger 11, fresh water heat exchanger 12, seawater feed pump 9. Concentrated salt water pump 10, fresh water pump 13. The evaporators of each effect are connected in series end to end in sequence, and the evaporators of each effect are equally divided into a seawater evaporation side and a heating steam side. The heating steam side inlet at the head end of the first effect evaporator 7 is connected to the exhaust port of the steam ejector 8 through a pipeline, and the suction port of the steam ejector 8 is connected to the end of the fourth effect evaporator 4 through a pipeline. The six-effect evaporator 2 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com