Combined turning rolling device used for processing taper hole

A combined device and turning technology, which is applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve the problems of not having turning function, not meeting energy-saving and efficient production standards, and single rolling function, so as to achieve good dimensional consistency, The effect of reducing surface roughness and saving processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the embodiments and drawings, but is not limited thereto.

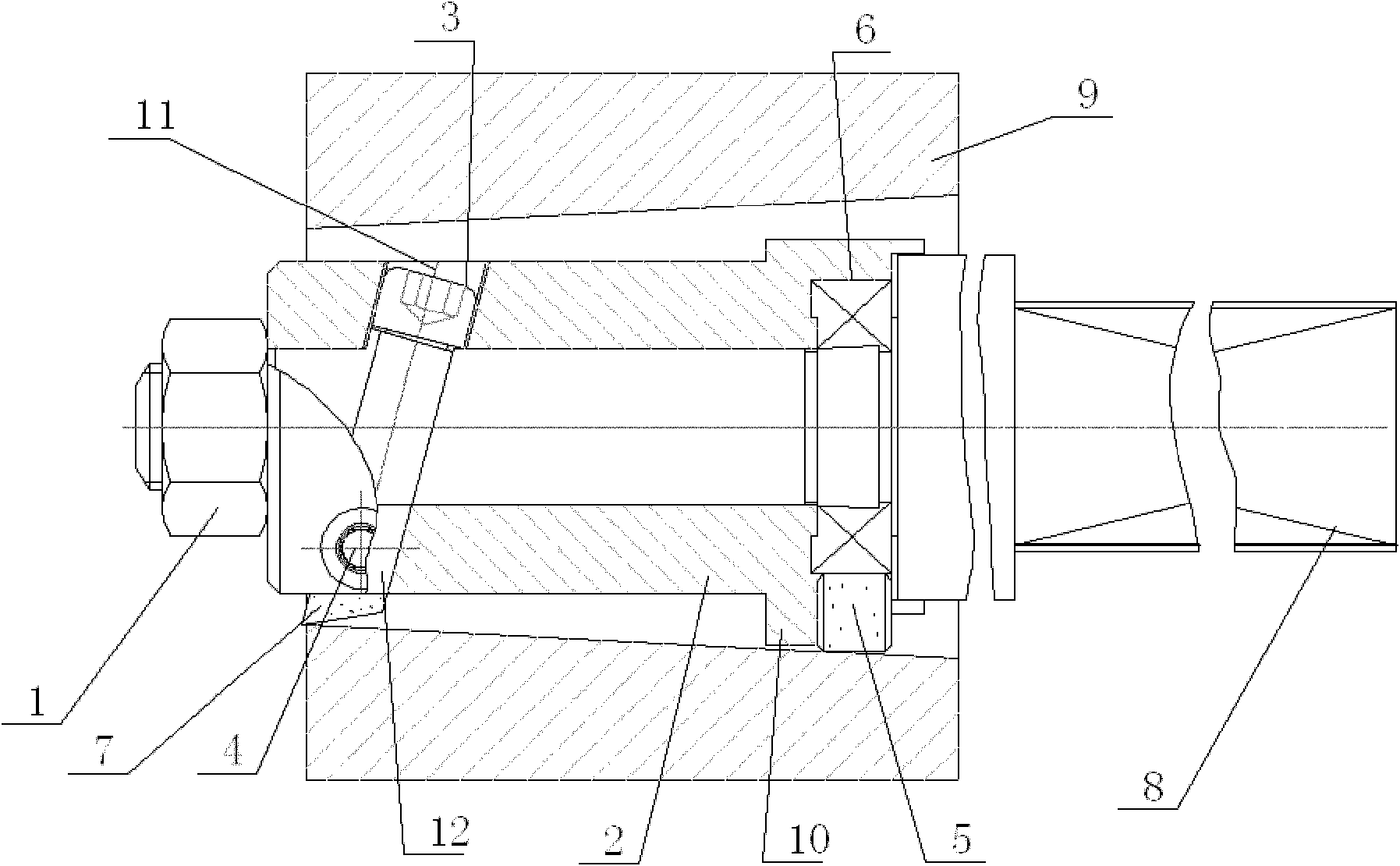

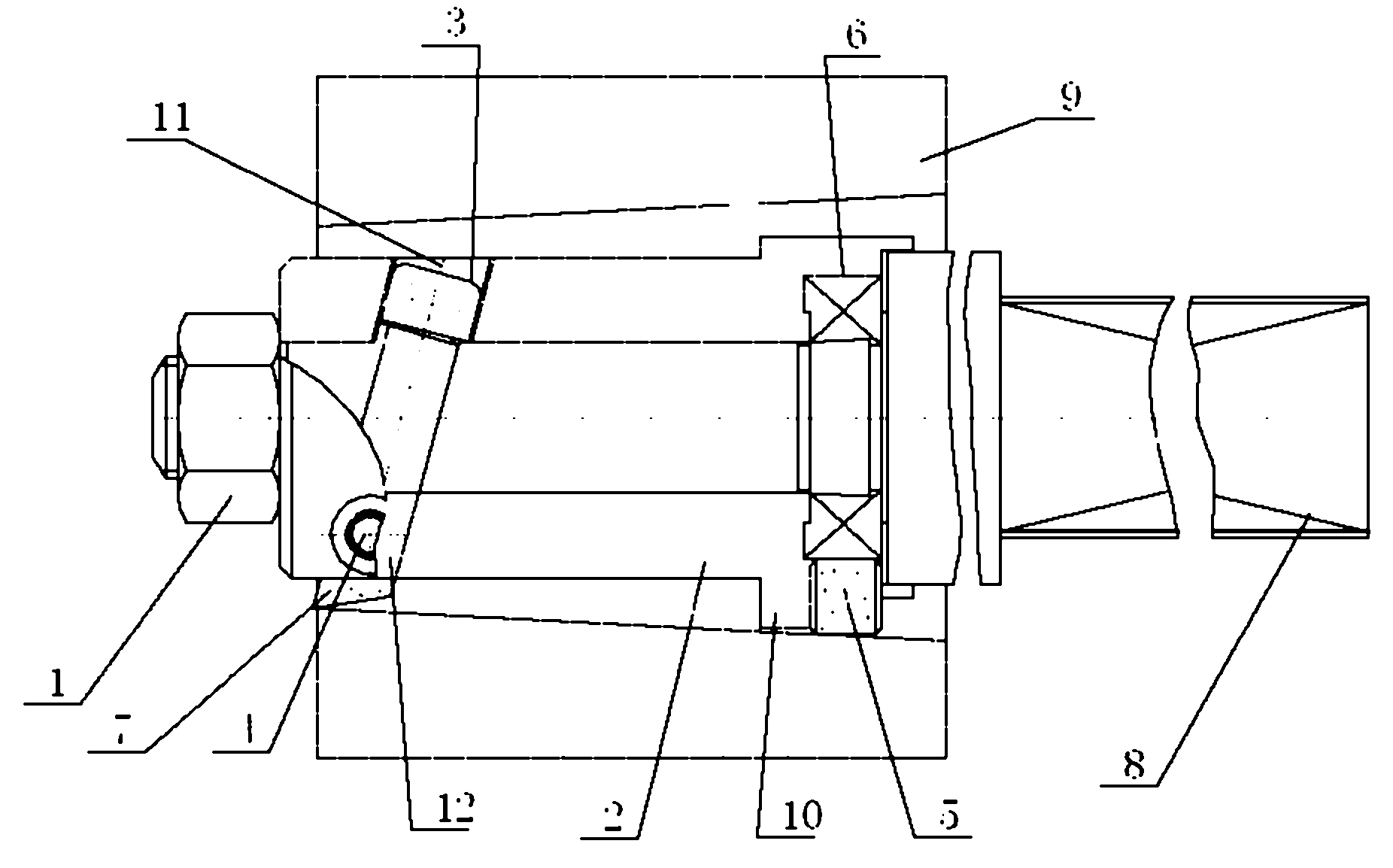

[0017] A turning and rolling combination device for processing taper holes, comprising a tool bar 8, a hard alloy knife 7 and a support sleeve 2, the front end of the tool bar 8 is fixedly provided with bolts, and the support sleeve 2 is set on the bolts through a nut 1 It is fixedly connected with the knife bar 8, and the front half of the support sleeve 2 is provided with an upward adjustment knife hole 11 and a downward adjustment knife hole 12. The lower part of the lower adjustment knife hole 12 is inclined away from the knife bar 8. The lower adjustment knife hole 12 is coaxially aligned; the hard alloy knife 7 is set through the upper adjustment knife hole 11 and the lower adjustment knife hole 12, and the hard alloy knife handle is fixed by the fine adjustment screw 3, and the fine adjustment screw 3 is connected with the upper a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com