Method for stably rolling tail of hot rolled thin band steel

A thin strip steel and stable technology, applied in the direction of metal rolling, metal rolling, rolling mill control devices, etc., can solve problems such as excessive speed, loss of stability at the tail of the strip, and large AGC adjustment, so as to reduce production costs, Effect of reducing production accidents and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

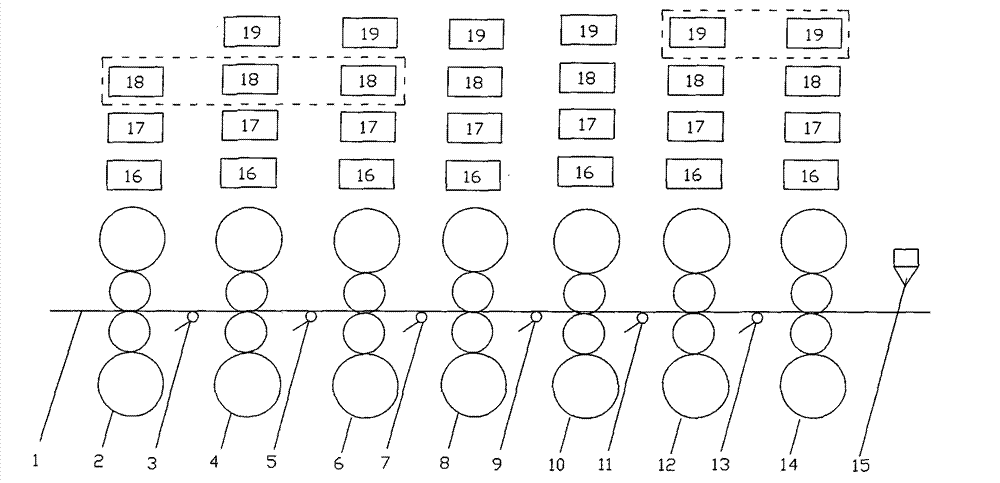

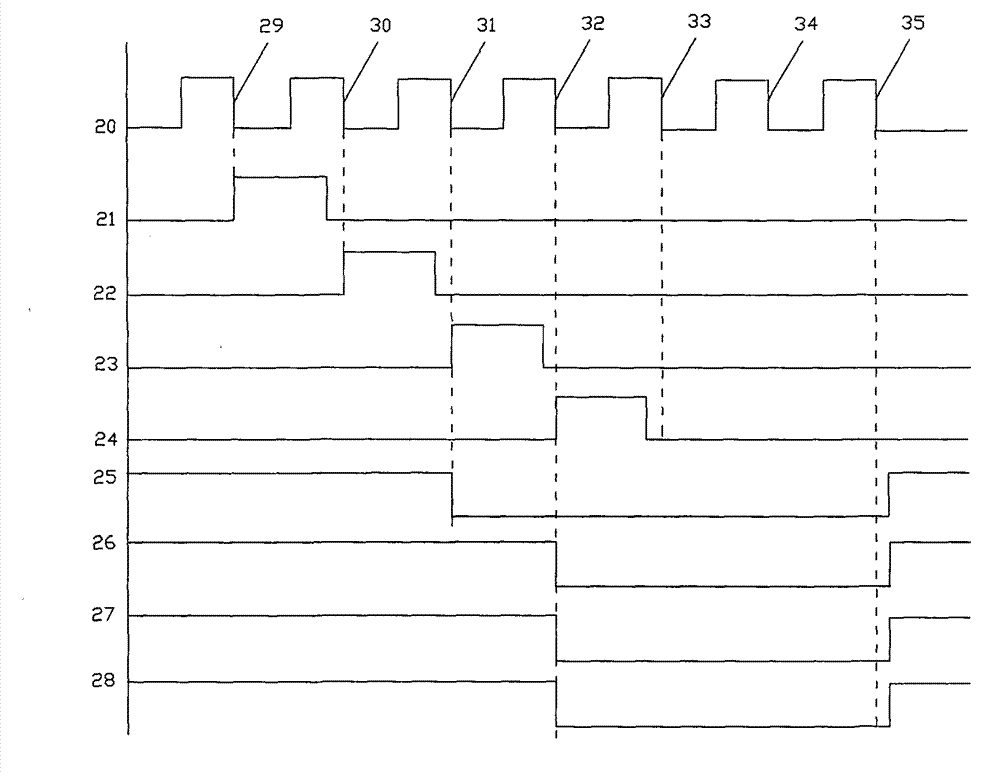

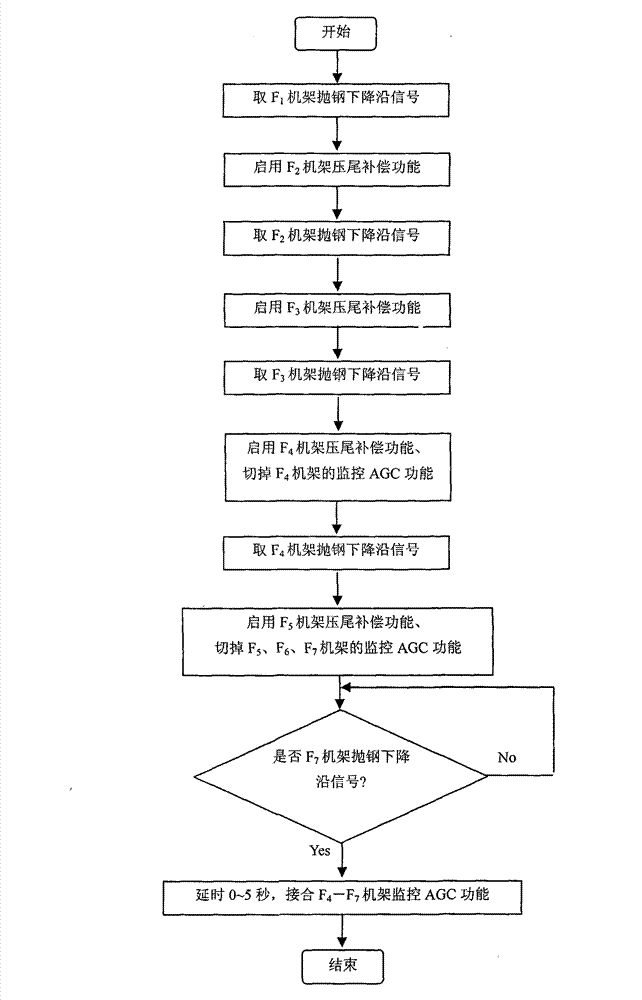

[0026] See figure 1 , the embodiment disclosed is a hot continuous rolling 1580mm seven-stand finishing mill and AGC functional composition diagram, thin strip steel 1 passes through F 1 Rack 2, 1# looper 3, F 2 Rack 4, 2# looper 5, F 3 Rack 6, 3# looper 7, F 4 Rack 8, 4# looper 9, F 5 Rack 10, 5# looper 11, F 6 Rack 12, 6# looper 13, F 7 The frame 14 and the X-ray thickness gauge 15 monitor the AGC to feed back the deviation between the actual plate thickness and the set value detected by the X-ray thickness gauge 15 to correct the roll gap, and control the thickness deviation to zero. The rolling method for the stable tail of the hot continuous rolling thin strip is to control the follow-up frame to monitor the AGC function 18 through the falling edge signal of the upstream frame, so as to avoid excessive and fast adjustment of the monitor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com