System for testing diode thermistor in high speed

A technology of thermistor and test system, applied in sorting and other directions, can solve the problems of narrow, only 15 ℃ to 30 ℃ temperature test, the test accuracy, labor intensity has not been improved, and the test device is small in size, etc. Achieve the effect of fast test speed, wide test temperature and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

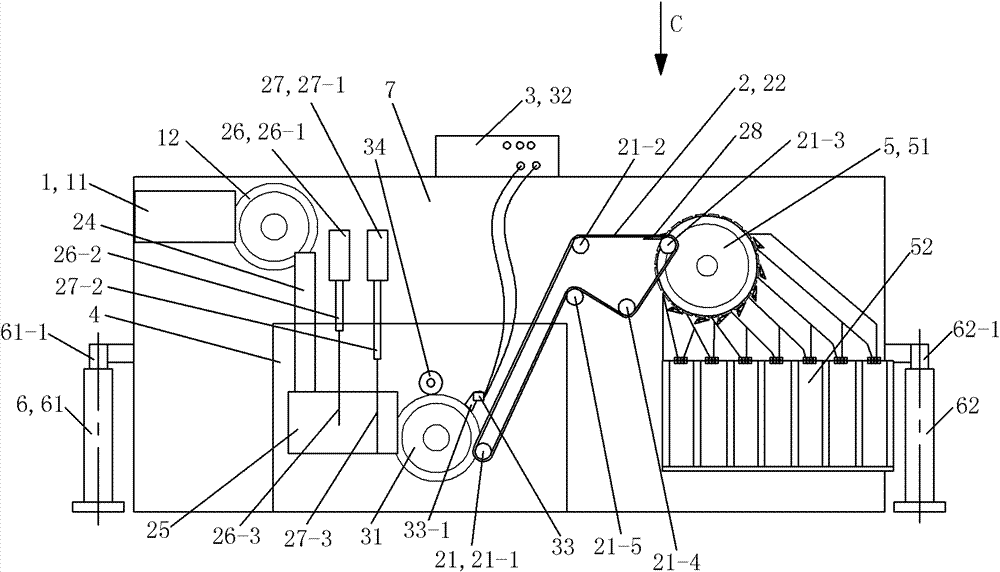

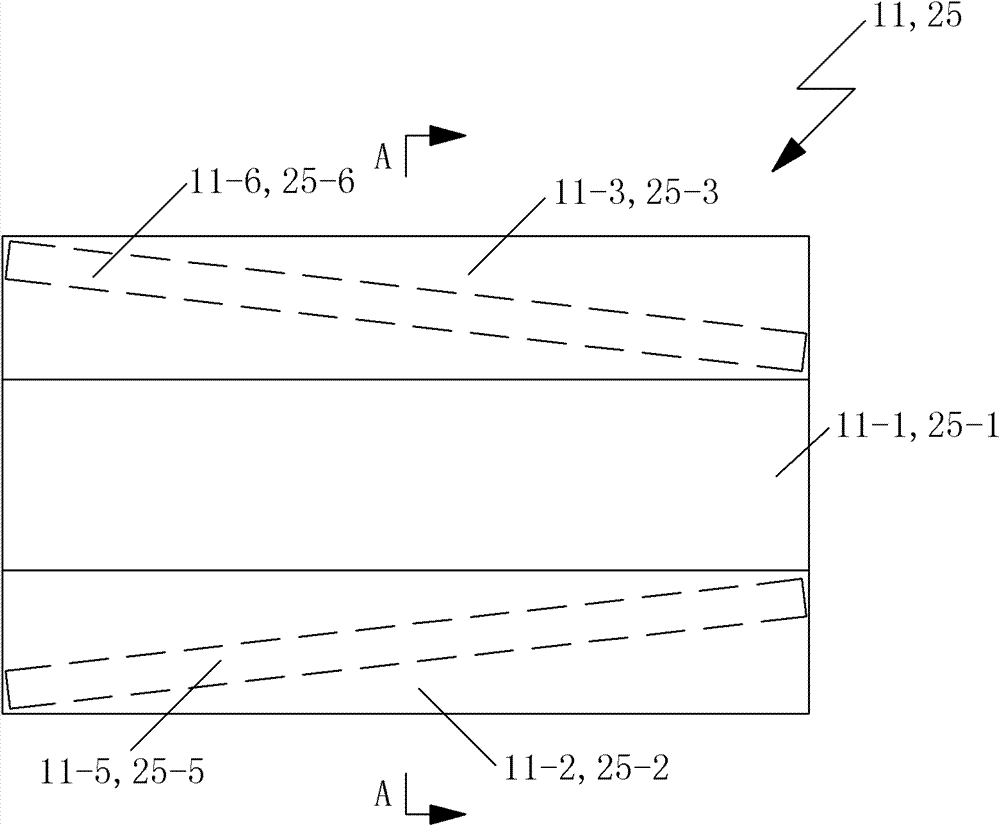

[0068] See figure 1 , The diode-type thermistor high-speed test system of this embodiment includes a discharge device 1, a conveying device 2, a test device 3, a constant temperature tank 4, a receiving device 5, a lifting device 6, a machine base 7, a transmission mechanism and a control device. Discharging device 1 , conveying device 2 , testing device 3 , receiving device 5 , transmission mechanism and control device are arranged on machine base 7 . The constant temperature tank 4 and the lifting device are all located on the ground, and the constant temperature tank 4 is located at the middle and lower part of the support 7, and the constant temperature tank 4 is filled with oil during use. A left-right vertical mounting plate is provided on the lower side of the left-right middle part of the machine base 7 , and the mounting plate is located in the constant temperature tank 4 . The discharge device 1 includes a discharge magnetic track 11 and a discharge magnetic wheel 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com