Sealant coating system adopting two-component distribution system

A two-component, dispensing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

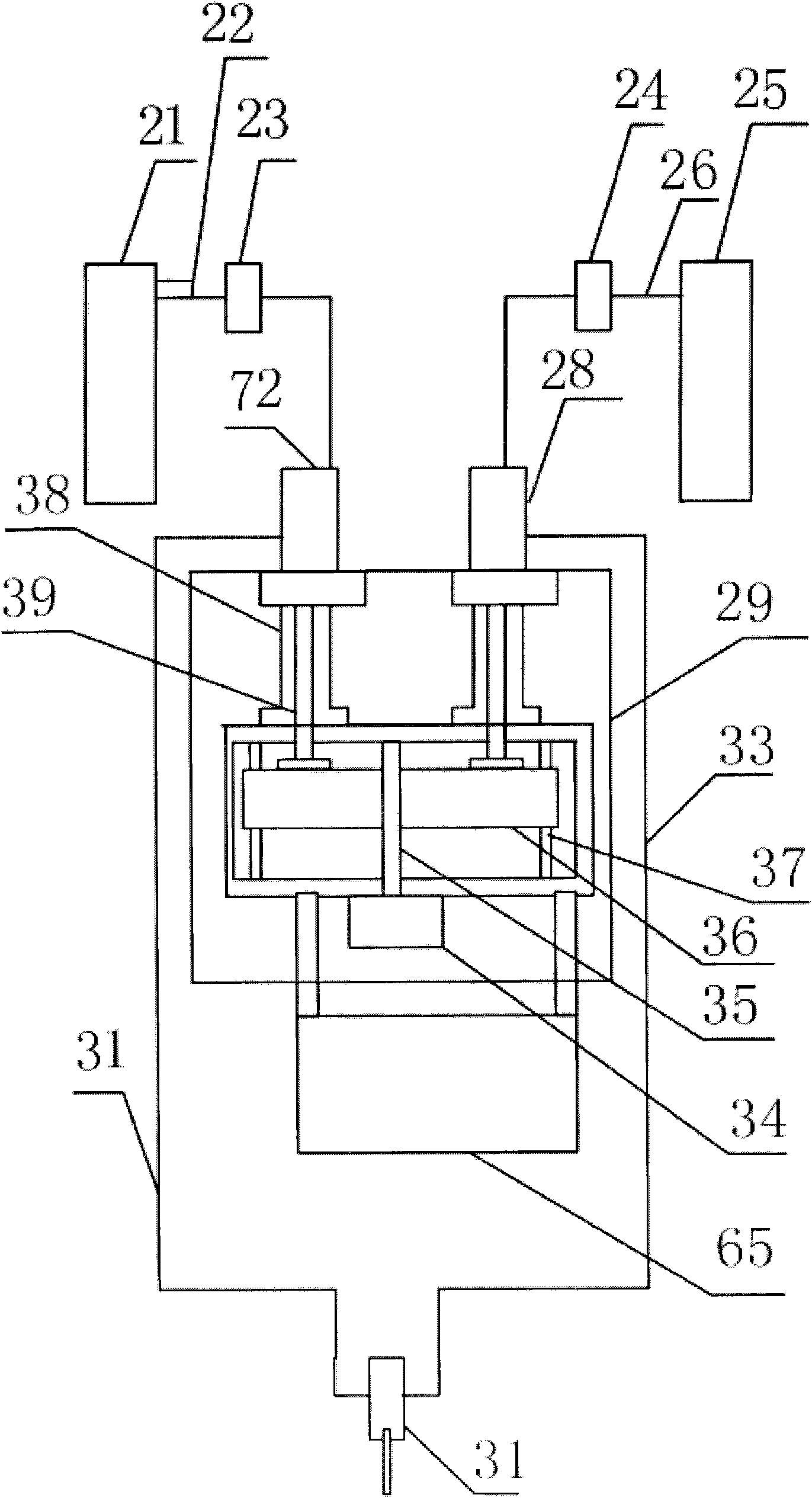

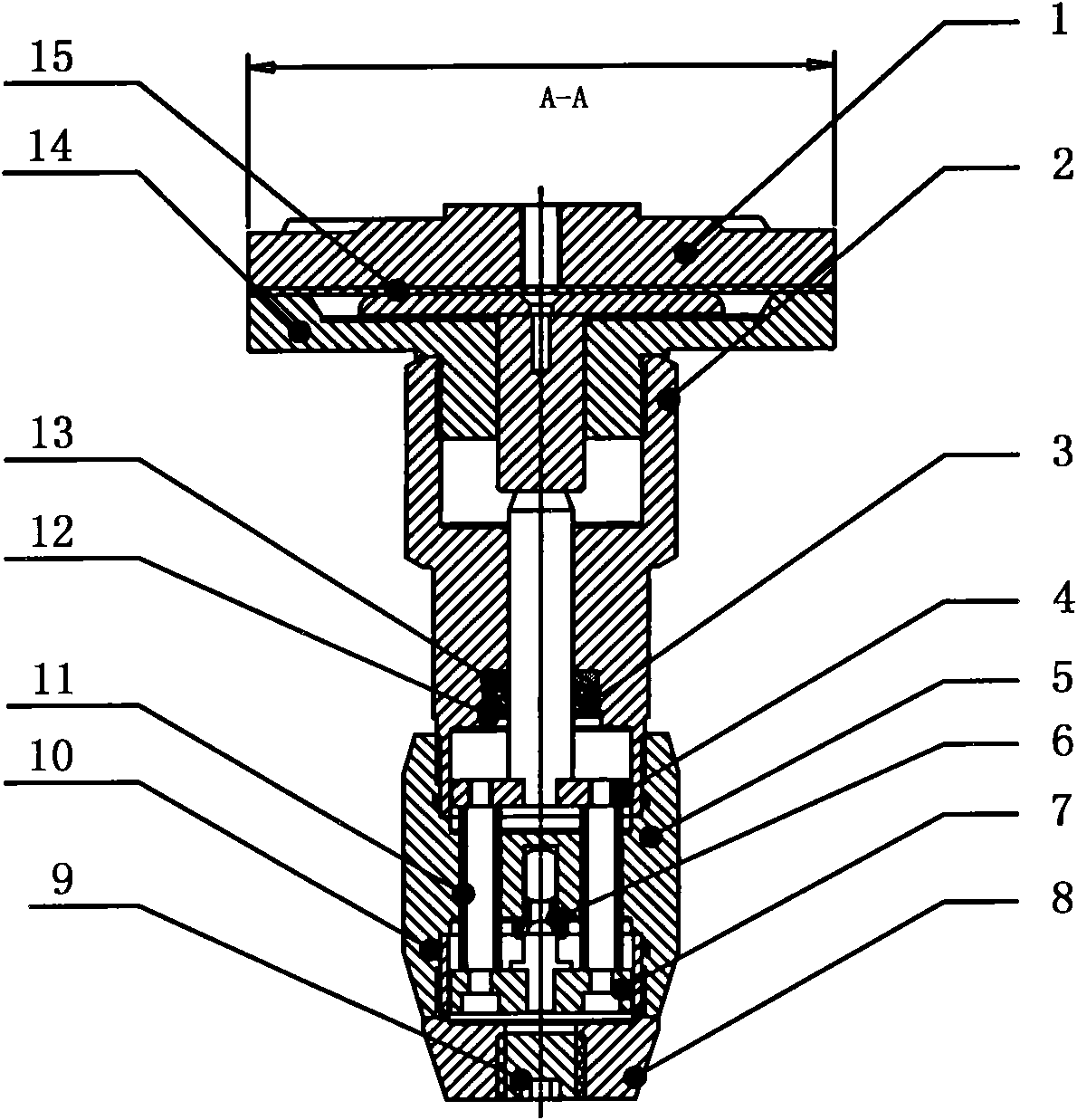

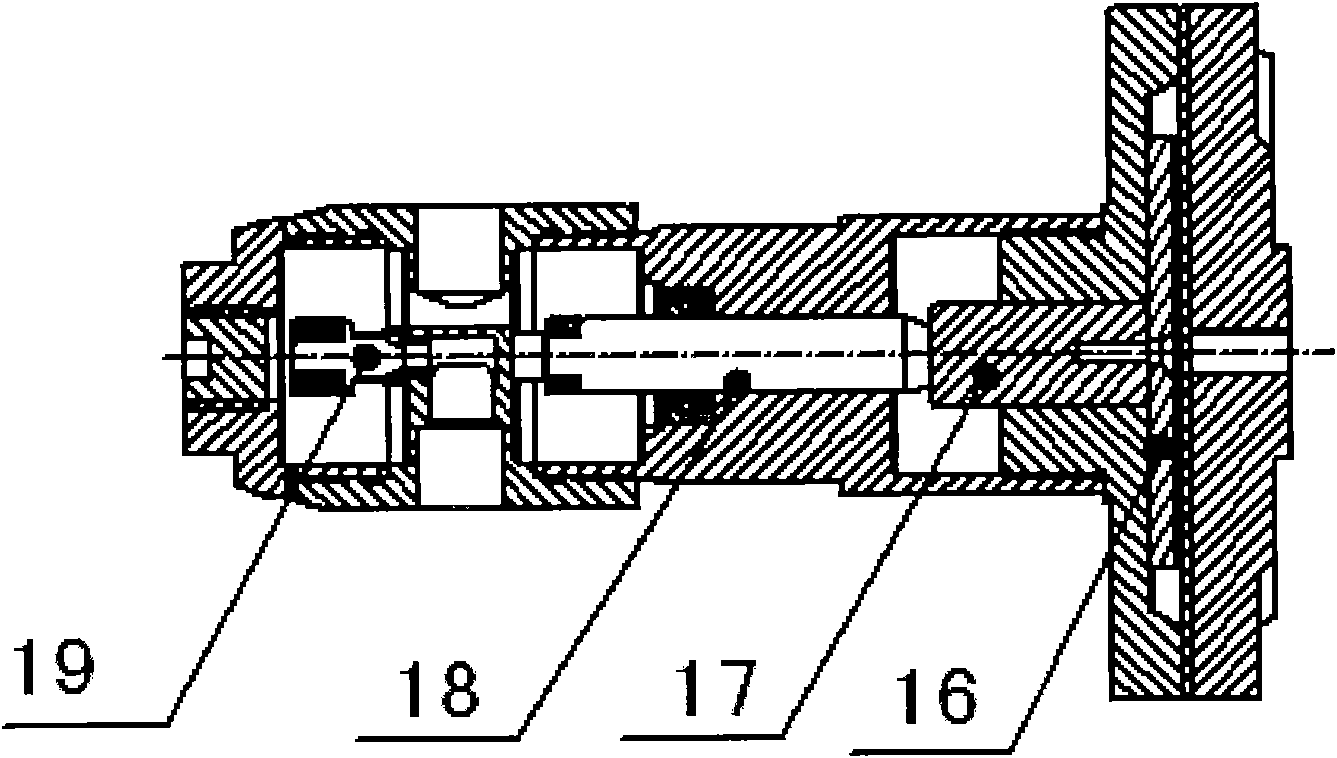

[0039] Such as figure 1 , Figure 4 Figure 5 , Figure 6 As shown, a dispensing system utilizing a two-component dispensing system includes a two-component proportioning system, a first material delivery system 21, a second material delivery system 25, and the first material delivery system 21 through a delivery pipeline 22. The first voltage regulator 23 connected, the second voltage regulator 24 connected to the second material delivery system 25 through the delivery pipeline 26;

[0040] The first voltage stabilizer 23 is connected to the input end of the first reversing device 27 on the two-component proportioning system through the delivery pipeline, and the second voltage stabilizer 24 is connected to the second reversing device 27 on the two-component proportioning system through the delivery pipeline. Connect to the input end of device 72, the output end of the first reversing device 28 is communicated with dispensing device 31 by pipeline, and the second output en...

Embodiment 2

[0062] Such as figure 1 , Figure 4 Figure 5 , Figure 6 As shown, a dispensing system utilizing a two-component dispensing system is characterized in that it includes a two-component proportioning system, a first material delivery system 21, a second material delivery system 25, and a delivery pipeline 22 with the first material The first voltage stabilizer 23 connected to the conveying system 21, the second voltage stabilizer 24 connected to the second material conveying system 25 through the conveying pipeline 26;

[0063] The first voltage stabilizer 23 is connected to the input end of the first reversing device 27 on the two-component proportioning system through the delivery pipeline, and the second voltage stabilizer 24 is connected to the second reversing device 27 on the two-component proportioning system through the delivery pipeline. Connect to the input end of device 72, the output end of the first reversing device communicates with dispensing device through pi...

Embodiment 3

[0068] Such as figure 1 , Figure 4 Figure 5 , Figure 6 As shown, a dispensing system using a two-component dispensing system includes a two-component proportioning system, the first input port of the dispensing valve passes through the delivery pipeline and the input of the first reversing device on the two-component proportioning system The second input port of the dispensing valve is connected to the input end of the second reversing device on the two-component proportioning system through the delivery pipeline.

[0069] The two-component proportioning system includes a base 71, the base 71 is set on at least one frame cylinder 29, two parallel guide posts are the first guide post 37, the second guide post, the first guide post 37, the second guide post The guide pillars are arranged in the frame cylinder body 29, and the two ends of a slide block 36 run through two parallel guide pillars respectively, that is, the first guide pillar 37 and the second guide pillar, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com