Production of polymerized ferric-aluminum chloride composite coagulating agent

A technology of polyferric aluminum chloride and coagulant, which is applied in the direction of flocculation/sedimentation water/sewage treatment, etc., to achieve the effects of reducing production costs, improving environmental value, and stabilizing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

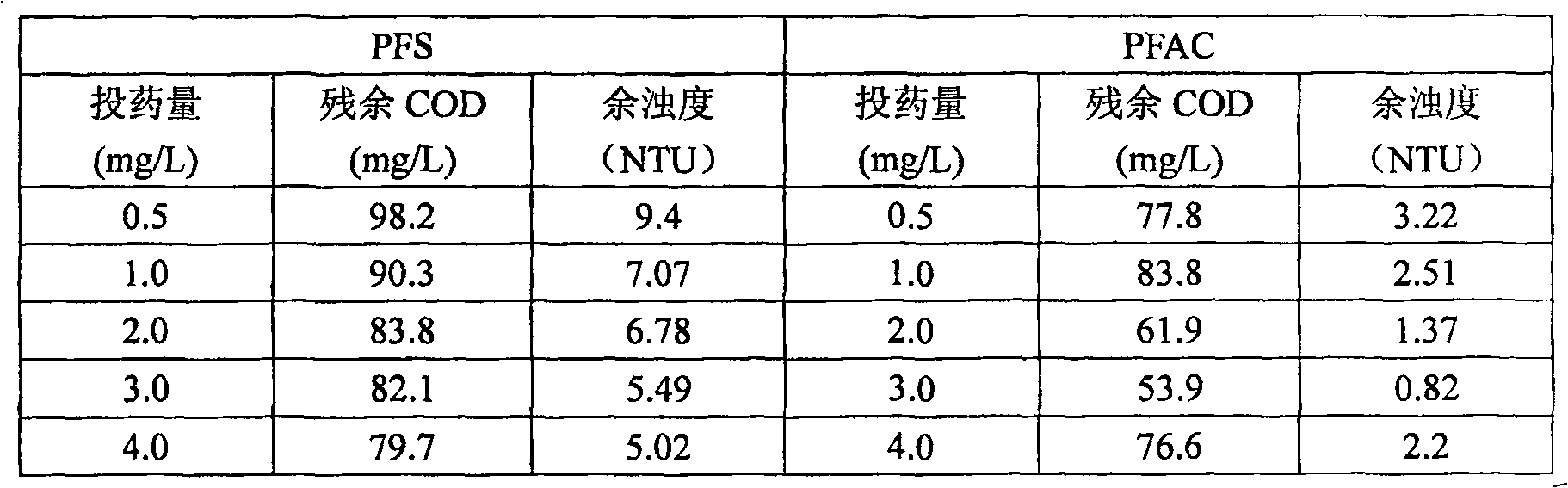

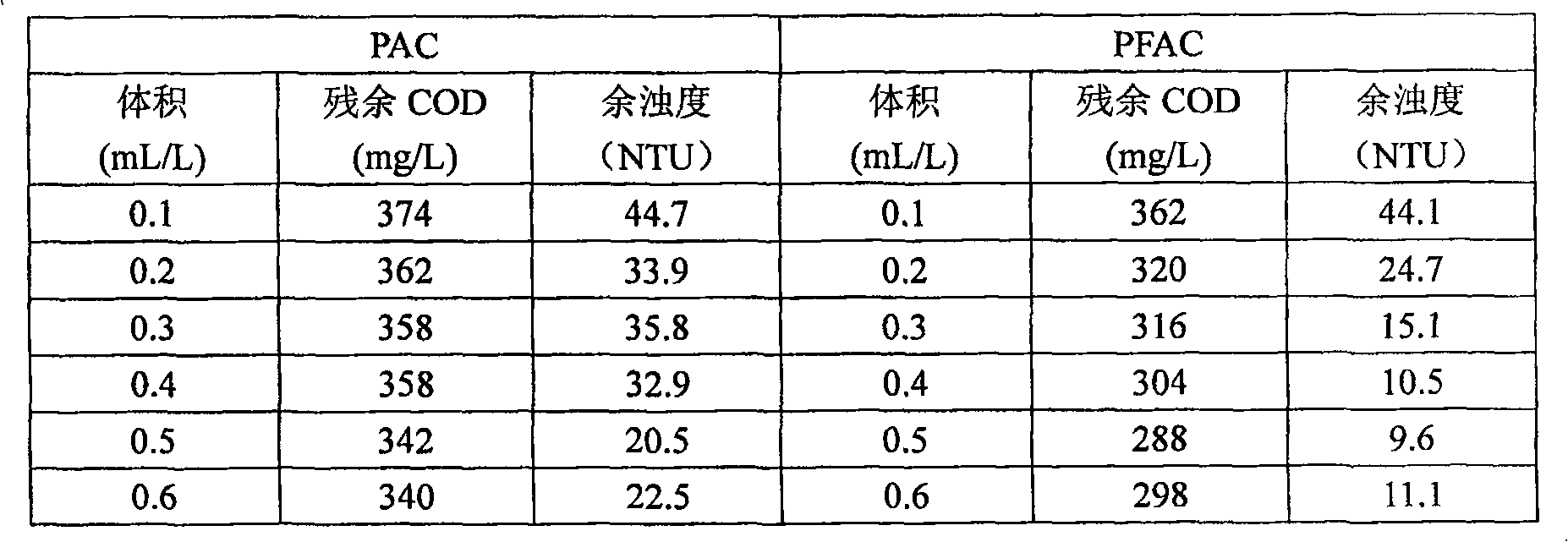

Examples

Embodiment 1

[0020] Take 347.1 g (300 mL) of hydrochloric acid pickling waste liquid with a specific gravity of 1.157 in a reaction kettle, and under normal pressure, add 7.7 g of sodium chlorate oxidant quantitatively in batches under conditions of stirring and a certain temperature (60-75° C.). Then add 20.0 g of calcium aluminate powder, and stir for 1.5 to 2.5 hours. Finally, filter while it is hot, add 7.4g sodium dihydrogen phosphate stabilizer to the filtrate, stir and dissolve to obtain Fe 2 o 3 The percentage content is 9.30%, Al 2 o 3 The percentage content is 2.72%, the basicity is 4.95%, Fe 2+ Stabilized polyferric aluminum chloride at concentrations below 0.1%.

Embodiment 2

[0022] Weigh 347.1 g (300 mL) of hydrochloric acid pickling waste liquid with a specific gravity of 1.157 in a reaction kettle, and under normal pressure, add 7.7 g of sodium chlorate oxidant quantitatively in batches under conditions of stirring and a certain temperature (60-75° C.). Then add 25.0 g of calcium aluminate powder, and stir for 1.5 to 2.5 hours. Finally, filter while it is hot, add 23.4g of sodium phosphate stabilizer to the filtrate, stir and dissolve to obtain Fe 2 o 3 The percentage content is 7.78%, Al 2 o 3 The percentage content is 3.34%, the basicity is 6.44%, Fe 2+ Stabilized polyferric aluminum chloride at concentrations below 0.1%.

Embodiment 3

[0024] Take 368.7g (300mL) of hydrochloric acid pickling waste liquid with a specific gravity of 1.229, 74mL of industrial hydrochloric acid and 15mL of distilled water in the reaction kettle, under normal pressure, add 8.3g in batches quantitatively under the conditions of stirring and a certain temperature (60-75°C). Sodium Chlorate Oxidizer. Then add 32.4g of calcium aluminate powder, and stir for 1.5 to 2.5 hours. Finally, filter while it is hot, add 30.6g of sodium phosphate stabilizer to the filtrate, stir and dissolve to obtain Fe 2 o 3 The percentage content is 7.77%, Al 2 o 3 The percentage content is 3.15%, the basicity is 6.17%, Fe 2+ Stabilized polyferric aluminum chloride at concentrations below 0.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com