Valve-type anti-blocking printer nozzle component

A nozzle assembly and printer technology, applied in the field of 3D printing, can solve the problems of nozzle blockage and limited anti-slip effect of the material guide pipe, and achieve the effect of reasonable structure and good thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

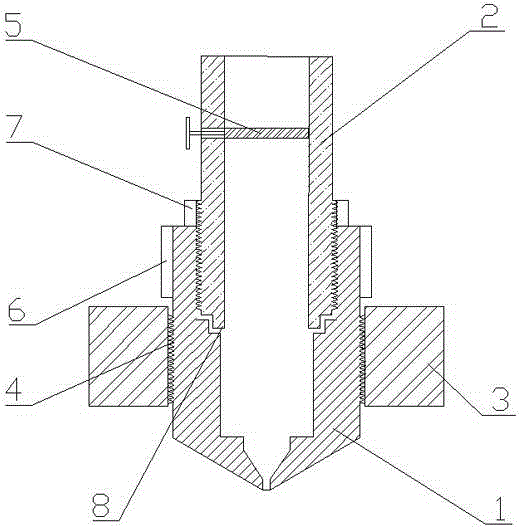

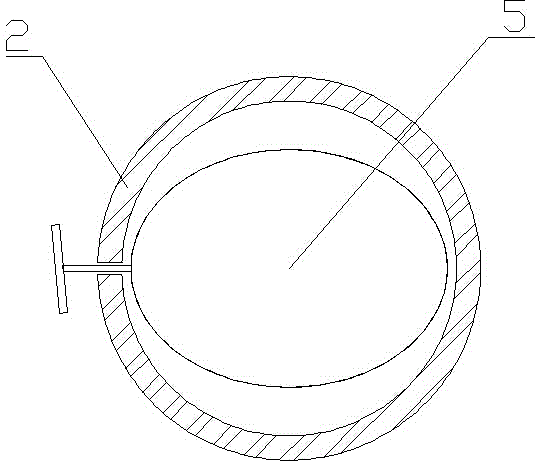

[0026] see figure 1 , the nozzle assembly of the valve-type anti-blocking printer of the present invention includes a nozzle 1, a feed throat 2, a heater 3, and a screw mechanism 4; the feed port of the nozzle 1 communicates with the discharge port of the feed throat 2 , the heater 3 is arranged on the outside of the nozzle and closely contacts the heated area of the nozzle; the nozzle, the feed throat and the heater are all fixedly connected by a threaded mechanism 4; the transition between the nozzle and the feed throat is provided with a leak-proof Step 8, the screw mechanism fixedly connecting the nozzle 1 and the feed throat 2 is set on the inner wall of the upper cavity of the nozzle, and the outer wall of the feed throat is correspondingly provided with a reverse thread mechanism, and the thread of the screw mechanism extends beyond the feed inlet of the nozzle ; It also includes the silk material valve 5 arranged near the junction of the feeding throat and the nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com