Inner core of USB (Universal Serial Bus) interface, interface and manufacture method

A universal serial bus and core technology, applied in the field of communication, can solve the problems of reducing production capacity, increasing costs, difficult positioning, etc., and achieving the effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

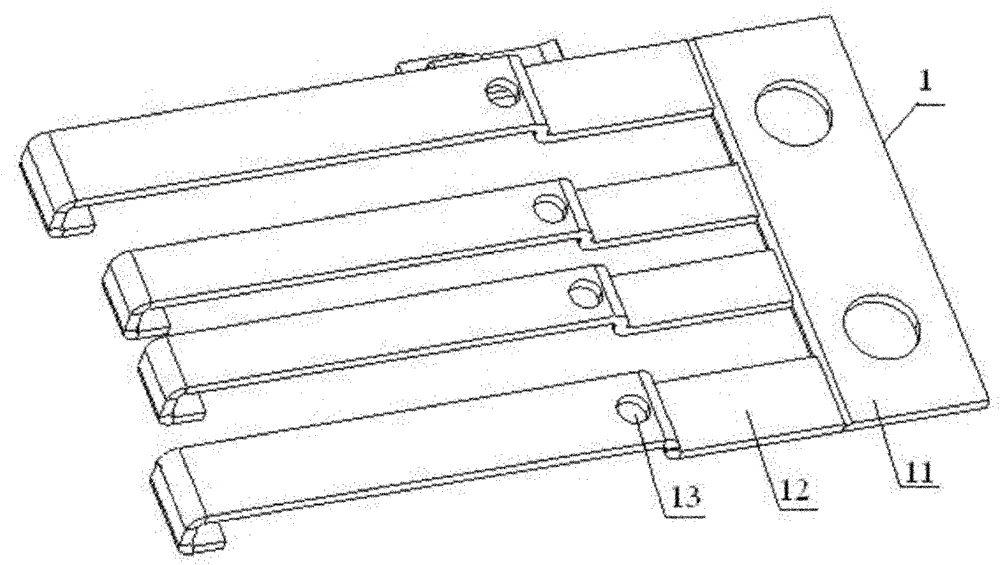

[0021] figure 1 It is a structural schematic diagram of the metal reed of the inner core of the USB interface according to the embodiment of the present invention, such as figure 1 As shown, the metal reed part 1 includes: an end part 11 and a plurality of metal reeds 12 , wherein the plurality of metal reeds 12 are sequentially fixed on the end part 11 .

[0022] In the actual production process, the above-mentioned metal reed part 1 can be formed by machining, for example, by stamping. In addition, the metal reed 12 and the end part 11 can also be connected by welding. In actual production, the most suitable manufacturing method can be selected in combination with production conditions and equipm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com