Detection instrument for detecting quality of lubricating oil by capacity effect and detection method thereof

A capacitance effect, lubricating oil technology, applied in the direction of material capacitance, etc., can solve the problems of not eliminating temperature and humidity changes, low accuracy, inaccurate measurement, etc., to achieve effective and fast detection methods, correct environmental effects, and improve circuit signal noise. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

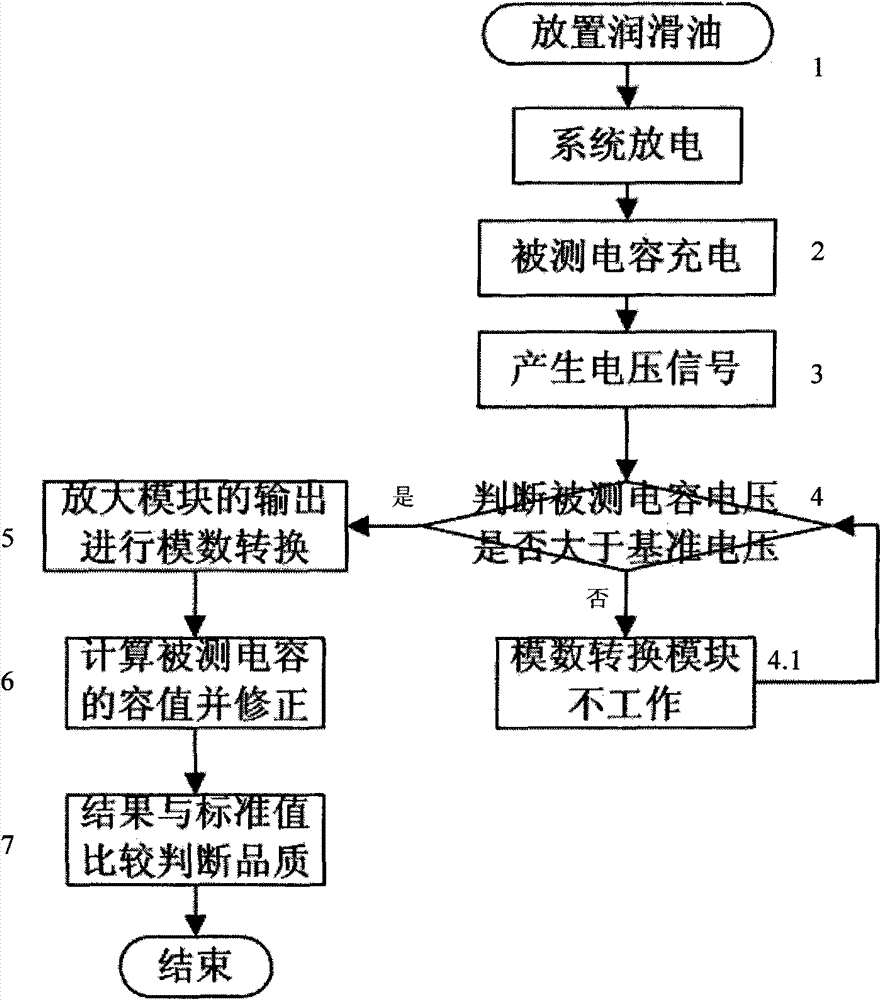

[0037] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

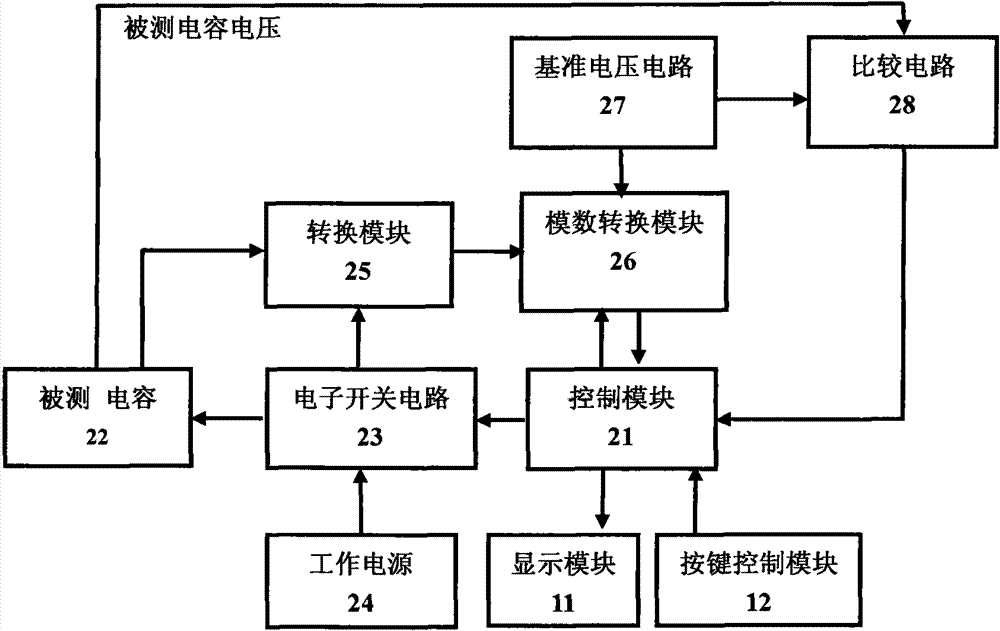

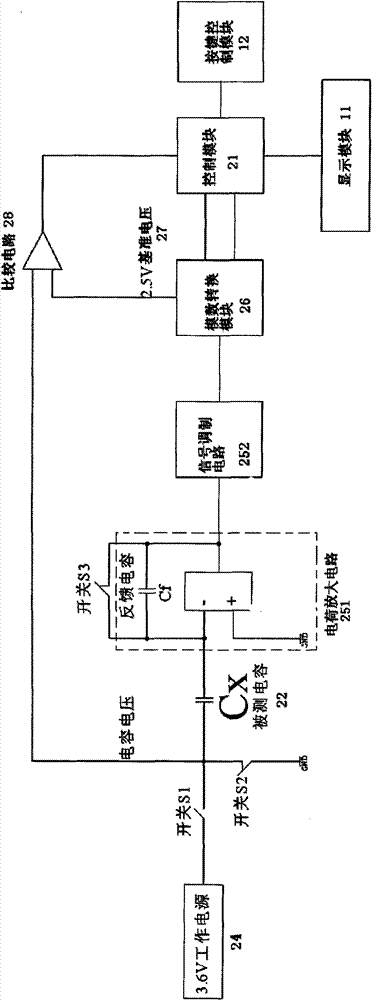

[0038] See figure 1 As shown, the circuit system 2 of the detector for detecting lubricating oil quality by using capacitance effect in the present invention includes a control module 21, an analog-to-digital conversion module 26 connected to the control module 21, an electronic switch circuit 23, a display module 11, and a key control module 12 and the output terminal of comparison circuit 28; wherein electronic switch circuit 23 is also connected with conversion module 25, operating power supply 24 and measured capacitance 22 respectively; The other end of the measured capacitor 22 is connected to the input of the conversion module 25; the output of the conversion module 25 is connected to the input of the analog-to-digital conversion module 26, and the analog-to-digital conversion module 26 is also connected to the reference voltage circuit 27, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com