Impeller generator and method for generating power

A technology for generators and generator rotors, applied to engine components, machines/engines, mechanical equipment, etc., can solve problems such as low power generation efficiency and heat loss, and achieve the effects of expanding applications and types, improving efficiency, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

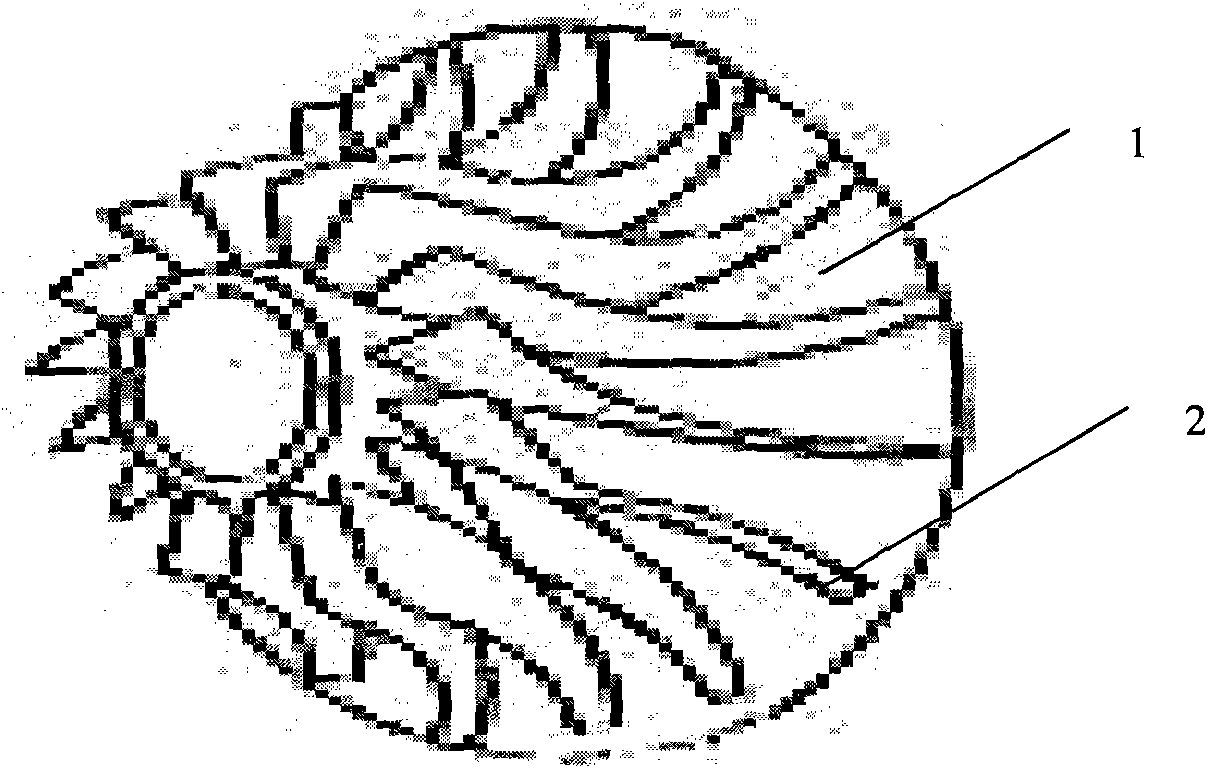

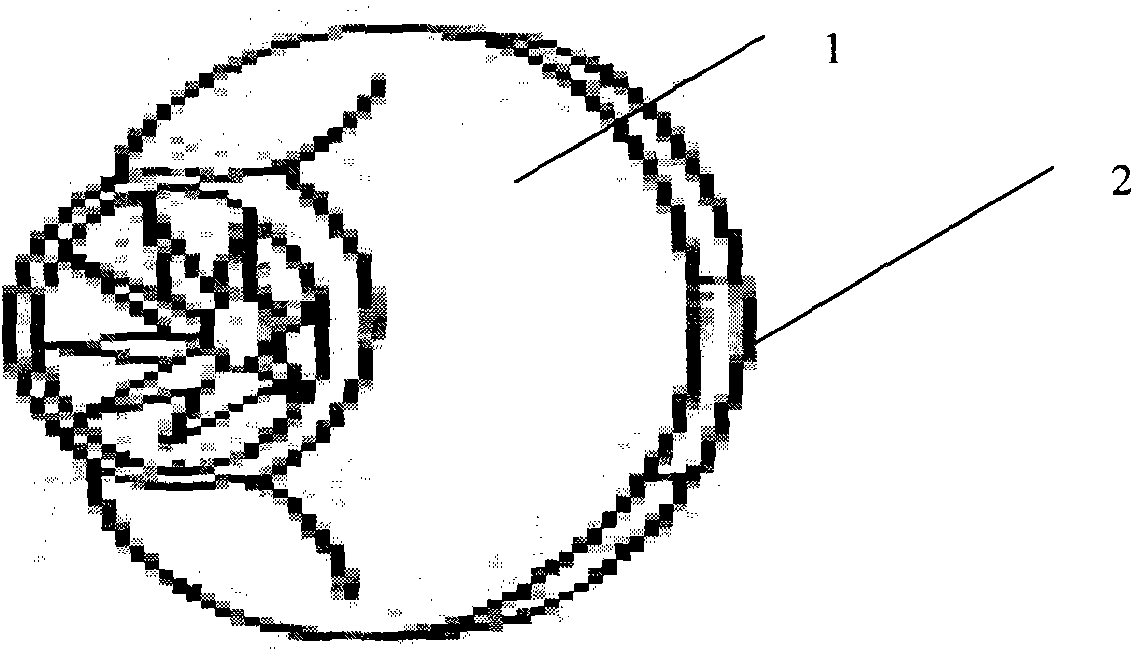

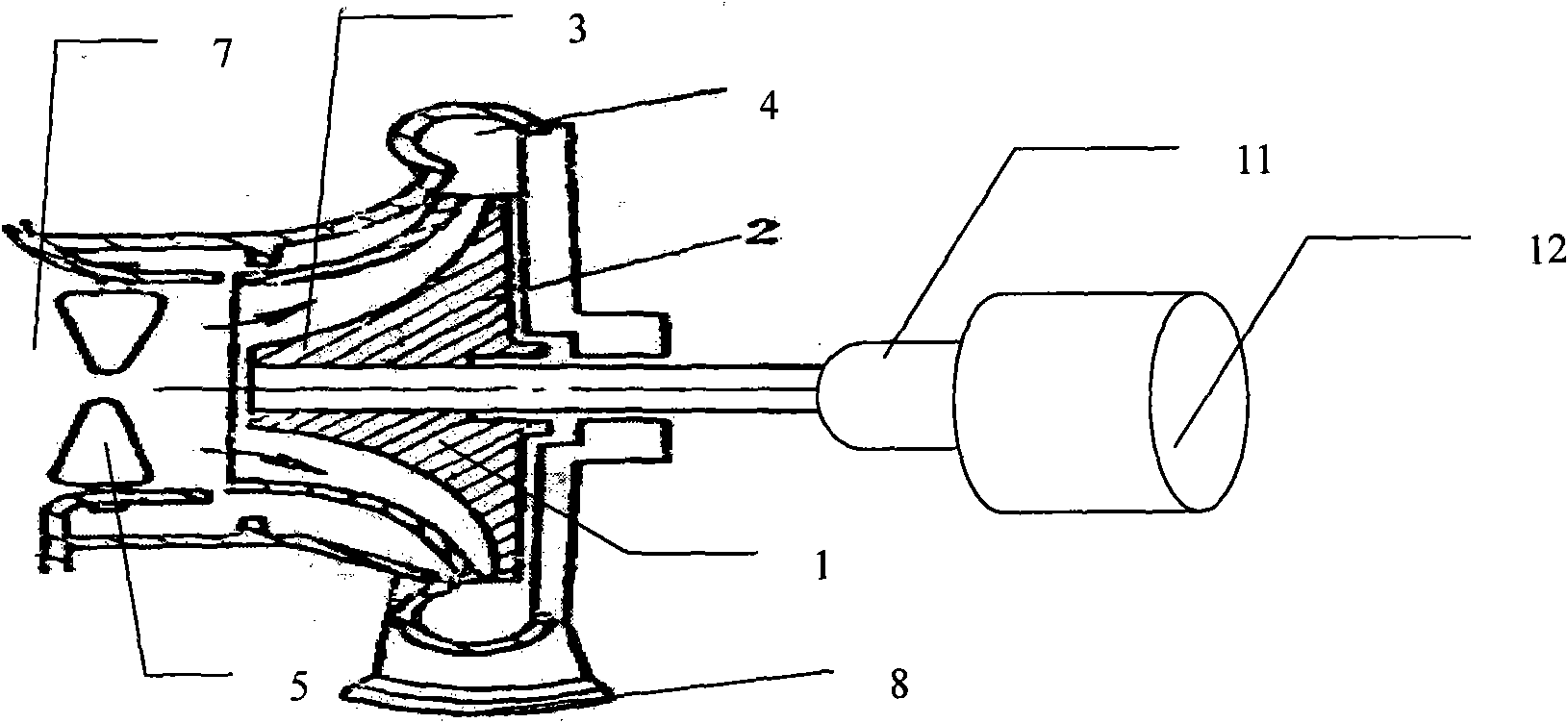

[0049] Embodiment 1: Single impeller generator with booster cavity

[0050] Such as image 3 As shown, the open impeller 2 is set in a housing 9, the fluid enters from the fluid inlet 7, and is sprayed on the impeller 2 through the nozzle 5 to push the impeller 2 to rotate. After the impeller drives the rotating shaft 3 to rotate, it is driven and arranged on the rotating shaft The rotor 11 of the generator rotates to form mutual motion with the stator 12 of the generator. The fluid sprays the nozzle 5 onto the impeller to convert the kinetic energy of the fluid into mechanical energy. The rotor and stator of the generator convert the mechanical energy into electrical energy to realize the power generation of the fluid. .

[0051] After the fluid is discharged from the fluid outlet 8, it enters the vortex chamber and is discharged after being pressurized.

[0052] In this case, R123 is used as the working medium, and the generating power is 5kw.

Embodiment 2

[0053] Embodiment 2: impeller generator with gearbox

[0054] Such as Figure 4 As shown, the fluid working medium for power generation in this example is high-pressure low-temperature organic working medium R134a. The fluid enters the cavity from the fluid inlet 7 and is sprayed onto the impeller 2 through the nozzle 5. The fluid is sprayed and expanded in the impeller to push the rotating shaft 3 Rotate, the rotating shaft converts the rotational speed to 3000 revolutions through the gearbox body 10, and the generator rotor 11 and the generator stator 12 are connected to the gearbox body 10, and the relative motion of the rotor and the stator generates electric energy, realizing the conversion of the kinetic energy of the fluid into electric energy .

[0055] In the above cases, liquid, gas, plasma, or a mixture of liquid and gas can be used to generate electricity, so that the waste heat and pressure can be fully utilized, or supplemented by solar energy, shallow surface t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com