Method for quickly assembling assembled corrugated culvert

A bellows and assembly technology, applied in the field of assembly of assembled culverts, can solve the problems of uneven bolt tightness, easy falling off of anti-corrosion layer, high labor intensity, low labor intensity, fast and convenient transfer, and ensure the quality of culverts. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

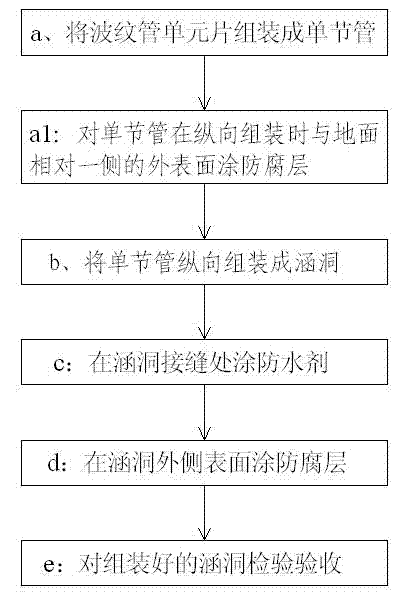

[0023] figure 1 It is a flow chart of the rapid assembly method for the installed bellows culvert.

[0024] As shown in the figure, the rapid assembly method of the assembled bellows culvert in this embodiment includes the following steps: a. Assembling the bellows unit pieces into a single-section pipe; b. Longitudinally assembling the single-section pipe into a culvert; The bellows unit pieces are placed on the assembly tool with the axis horizontal and assembled. The bellows unit is assembled on the tooling in a horizontal manner with the axis, and the operator stands up to work, with low labor intensity and high efficiency; the assembly tooling can be designed by yourself, for example, an idler supporting the bellows unit can be set on a support frame It can be realized by setting a driving device on the support frame to drive the unit piece to rotate around the roller group.

[0025] In this embodiment: it also includes the step a1 arranged between step a and step b: co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com