Pretreatment method of extraction of target product in fermentation liquor

A fermented liquid and pretreatment technology, applied in the direction of fermentation, etc., can solve the problems of high investment cost of pretreatment equipment, reduce cleaning frequency of ultrafiltration membrane, etc., and achieve suitable large-scale industrial production, easy control and maintenance, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

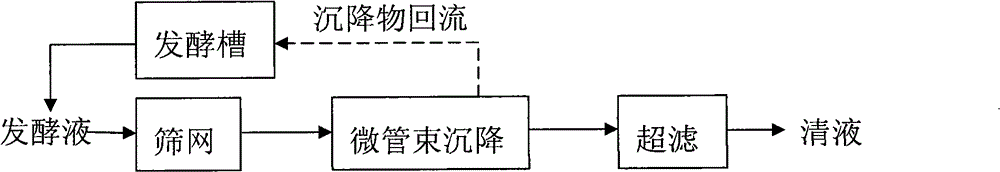

Method used

Image

Examples

Embodiment 1

[0026] Grinding the liquor distiller's grains, adding 2 to 10 ml of water to 1 g of the crushed distiller's grains (wet weight, water content 60%) to prepare a fermentation stock solution; 0.4-2wt% of bacteria is inserted into Lactobacillus casei (ie, 0.4-2g of Lactobacillus casei cell mass obtained after centrifugation is added to 100g fermentation stock solution), and after anaerobic fermentation at 35°C for 48-96 hours, a lactic acid fermentation liquid is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| surface load factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com