Optical glass strip rolling and moulding device

An optical glass, roll forming technology, applied in glass forming, glass calendering, glass manufacturing equipment and other directions, can solve the problems of inconsistent cooling speed between the upper and lower sides, reducing the utilization rate of glass sheet materials, and inconsistency in the size of rounded corners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

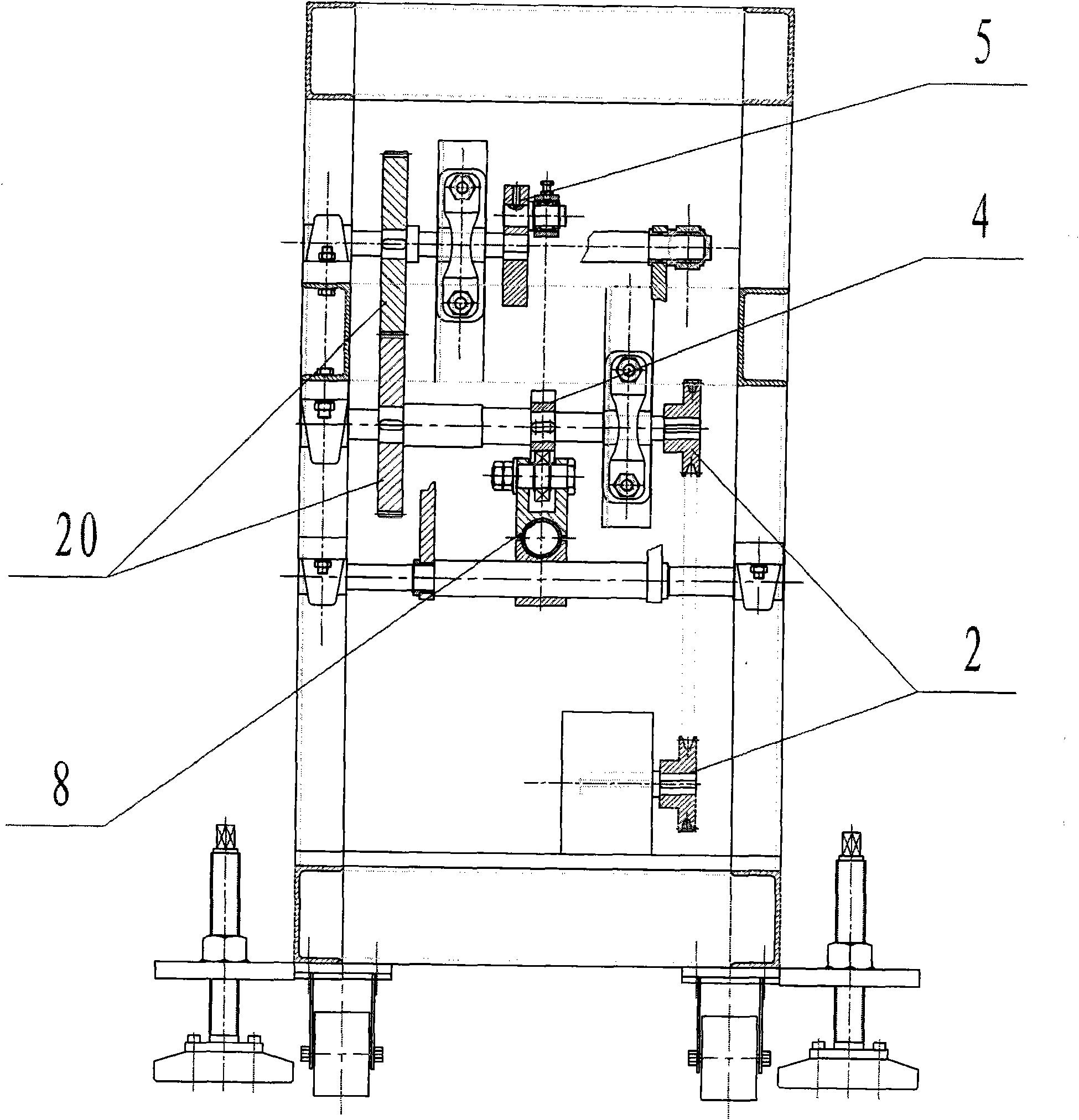

[0017] Such as figure 2 , 3 , shown in 4 and 5: the present invention is fixed on frame 1 and drive pulley 3 to drive a pair of cylindrical gears 20 that are completely identical in size and meshed up and down. The crank is installed coaxially with the upper cylindrical gear 20. The eccentric hole is connected with the moving end of the rocker 7 and the end of the support rod 18 through the connecting rod 6. The eccentricity (crank length) is half of the roller stroke, and the length of the rocker 7 is eccentric Eleven to twelve times the distance. The cam 4 is coaxially installed with the lower cylindrical gear 20. By pushing the small roller at one end of the linear lever 8 to move up and down, the triangular lever 9 is driven to lift (down) the support rod 18, and the support rod 18 falls into the top support roller of the triangular lever 9. In the groove of 19, the support rod 18 can move horizontally with the crank linkage mechanism when it moves up and down. The val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com