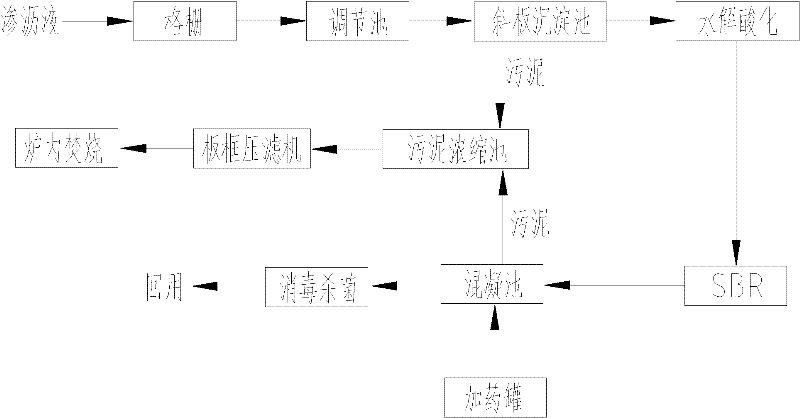

Treatment device and treatment process method for leachate from waste incineration plants

A waste incineration and treatment device technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve high transportation costs, treatment system impact, efficiency, effect, and investment costs less than ideal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

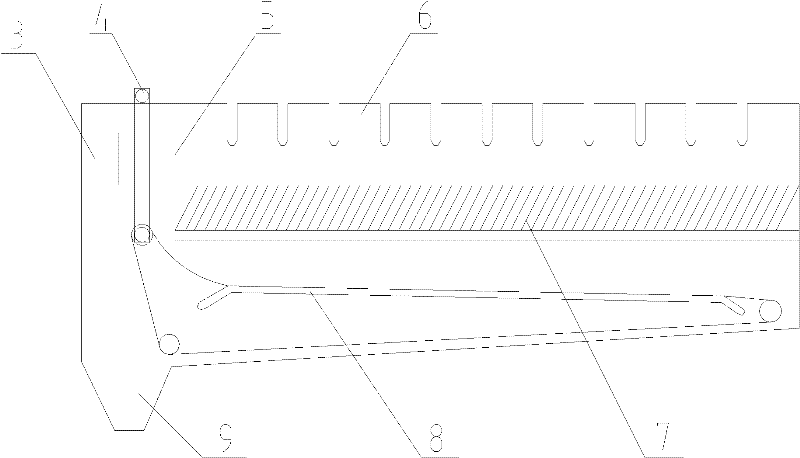

[0022] The specific implementation method of the present invention will be described below in conjunction with the accompanying drawings.

[0023] 1. The leachate collected from the garbage storage pit first enters the grid room, removes coarse suspended solids and sundries through the 75×75mm coarse grid, and then enters the 15×15 fine grid to intercept the sewage and pass through the coarse grid Relatively small suspended solids and sundries are filtered to protect the normal operation of subsequent treatment facilities.

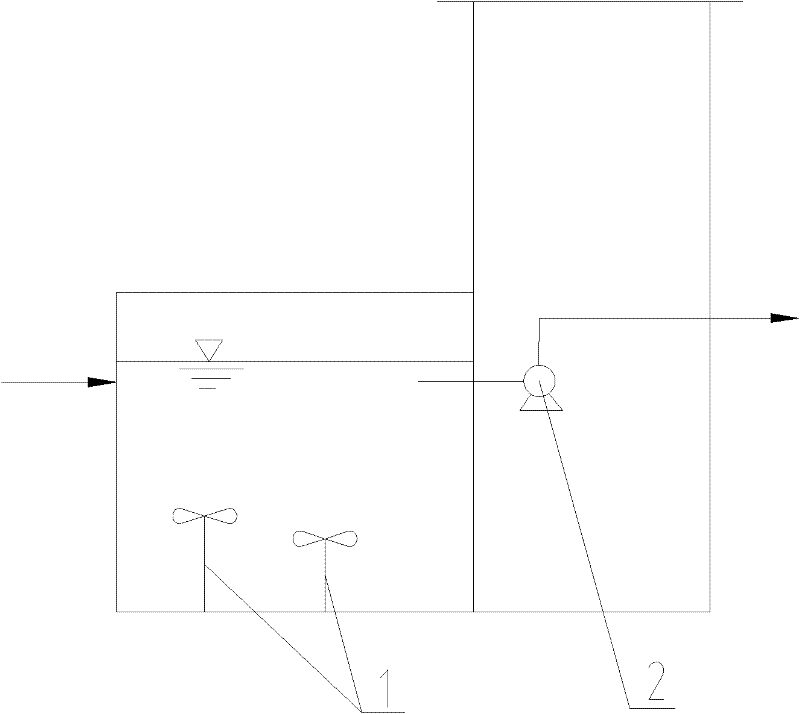

[0024] 2. The leachate output of the incineration plant often fluctuates with factors such as the moisture content of the garbage and weather changes, so the setting

[0025] The regulating tank regulates the quality and quantity of the leachate, and plays the role of pretreatment and buffering. The regulating pool is an underground steel-concrete anticorrosion structure, such as figure 2 As shown, a stirring device 1 is set in the pool to adjust the qu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com