Wastewater treatment process of flat membrane bioreactor and reverse osmosis comprehensive membrane integrated system

A technology of membrane bioreactor and bioreactor, which is applied in the direction of osmosis/dialysis water/sewage treatment, textile industry wastewater treatment, oxidized water/sewage treatment, etc. It can solve the problem of unstable water quality and difficult to remove and biodegradable substances , Difficult to deal with and other problems, to achieve stable and reliable treatment of water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The garment laundry wastewater mainly contains silicon-containing organic softeners, silicon-free organic softeners, surfactants, enzymes, oxidants, reducing agents, polymer organics and inorganic salts. The main components of wastewater are as follows:

[0039] Table 1: Main components in laundry wastewater from textile factories

[0040] pH

Color

COD cr

BOD 5

TN

TP

(NTU)

(mg / L)

(mg / L)

(mg / L)

(mg / L)

7~12

8~64

18~1778

112~2890

335~810

3~24

6~21

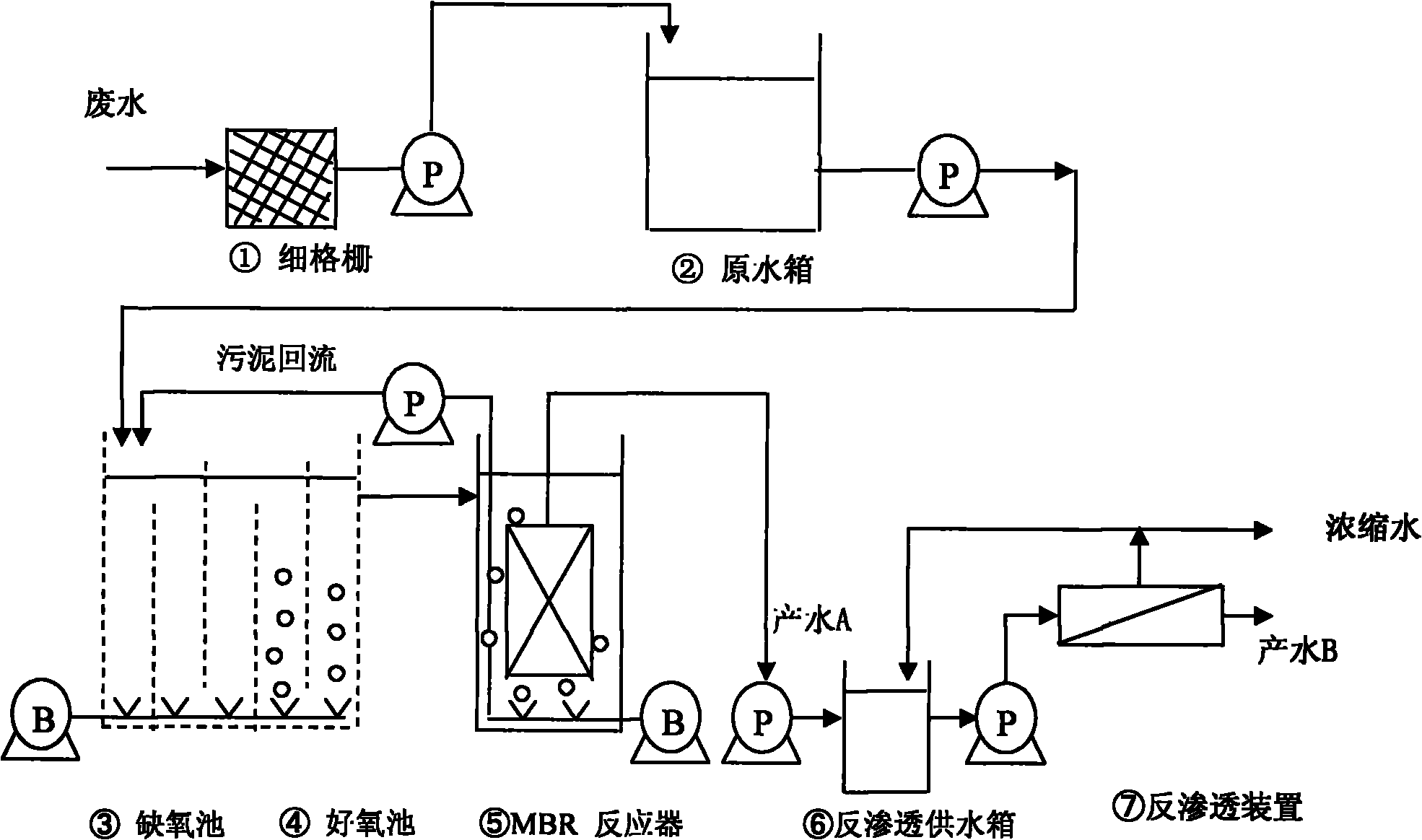

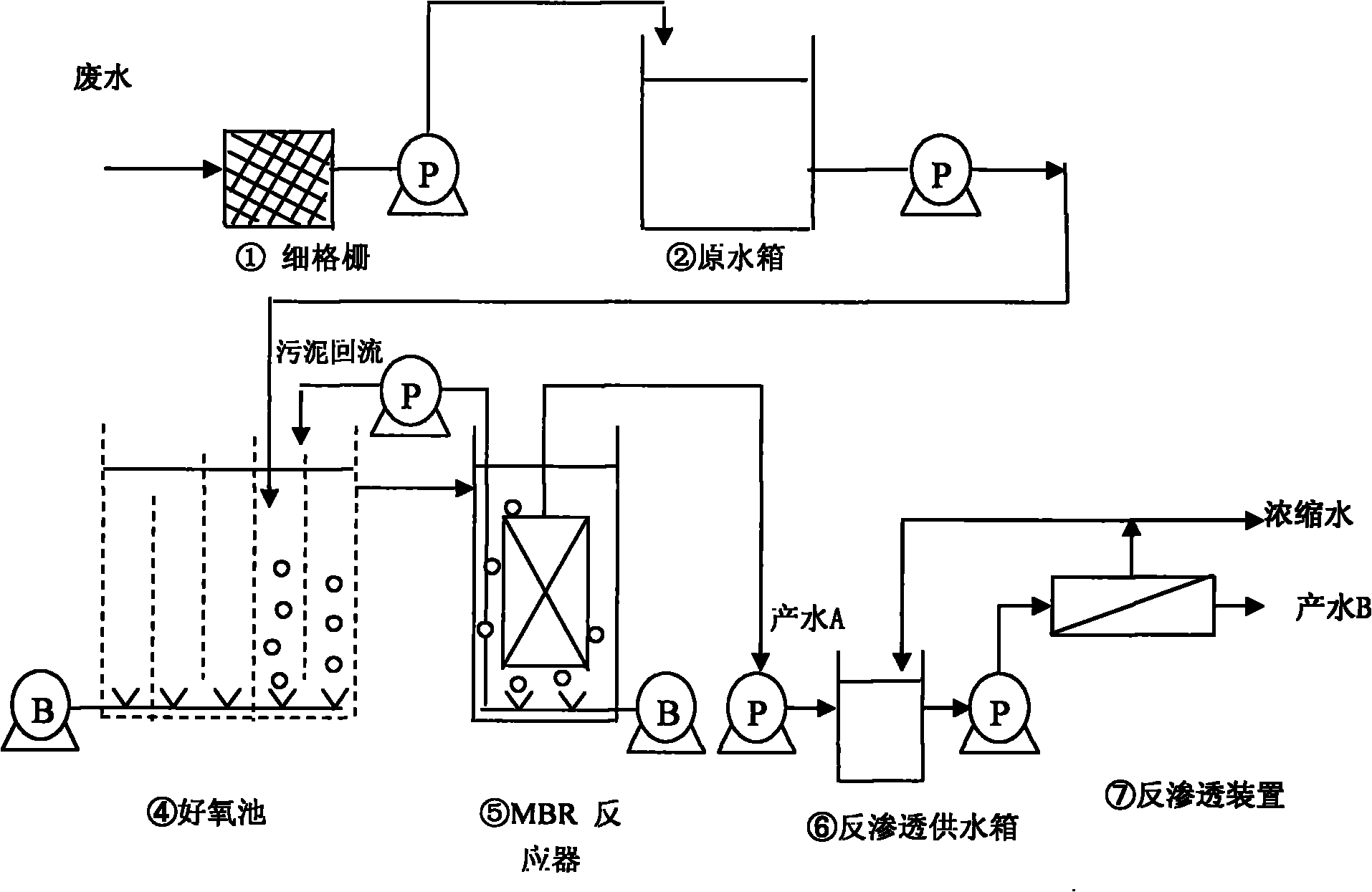

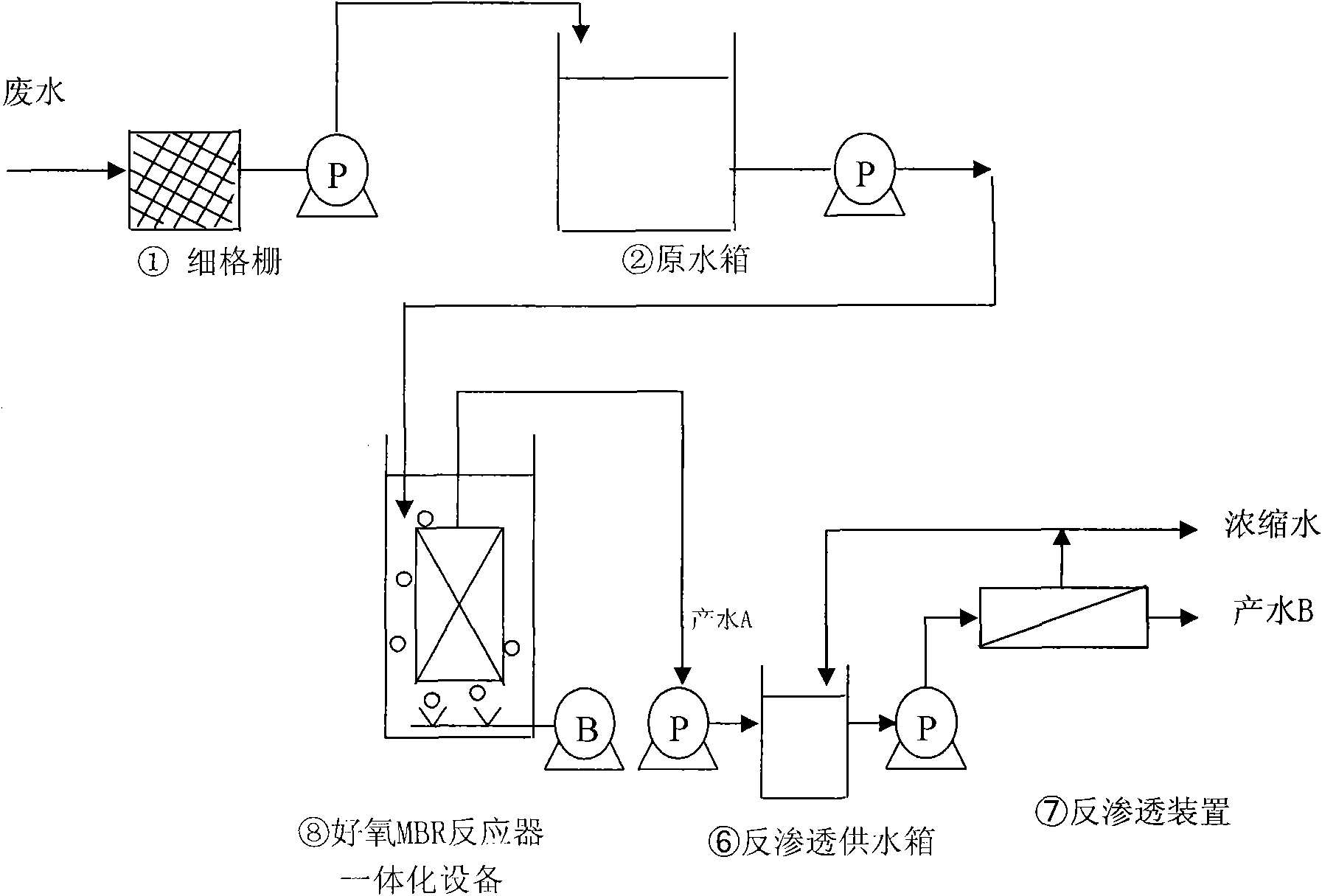

[0041] The garment laundry wastewater generated in the factory first passes through the fine grid (①) with a spacing of figure 2 ). In the membrane bioreactor (MBR), a submerged MBR membrane module is set up, which is composed of a membrane element box and an aeration box. The membrane element box is equipped with 9m 2 PVDF flat membrane element (the flat membrane element is produced by Japan Toray Company, the model is TSP-50100). The flat polyvinylidene fluoride film contains a composite film ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com