Device and method for processing valve core

A processing device and processing method technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of reducing the strength of the valve core, difficult to control product quality, and air leakage of the valve core, so as to improve the service life and save labor costs. , the effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

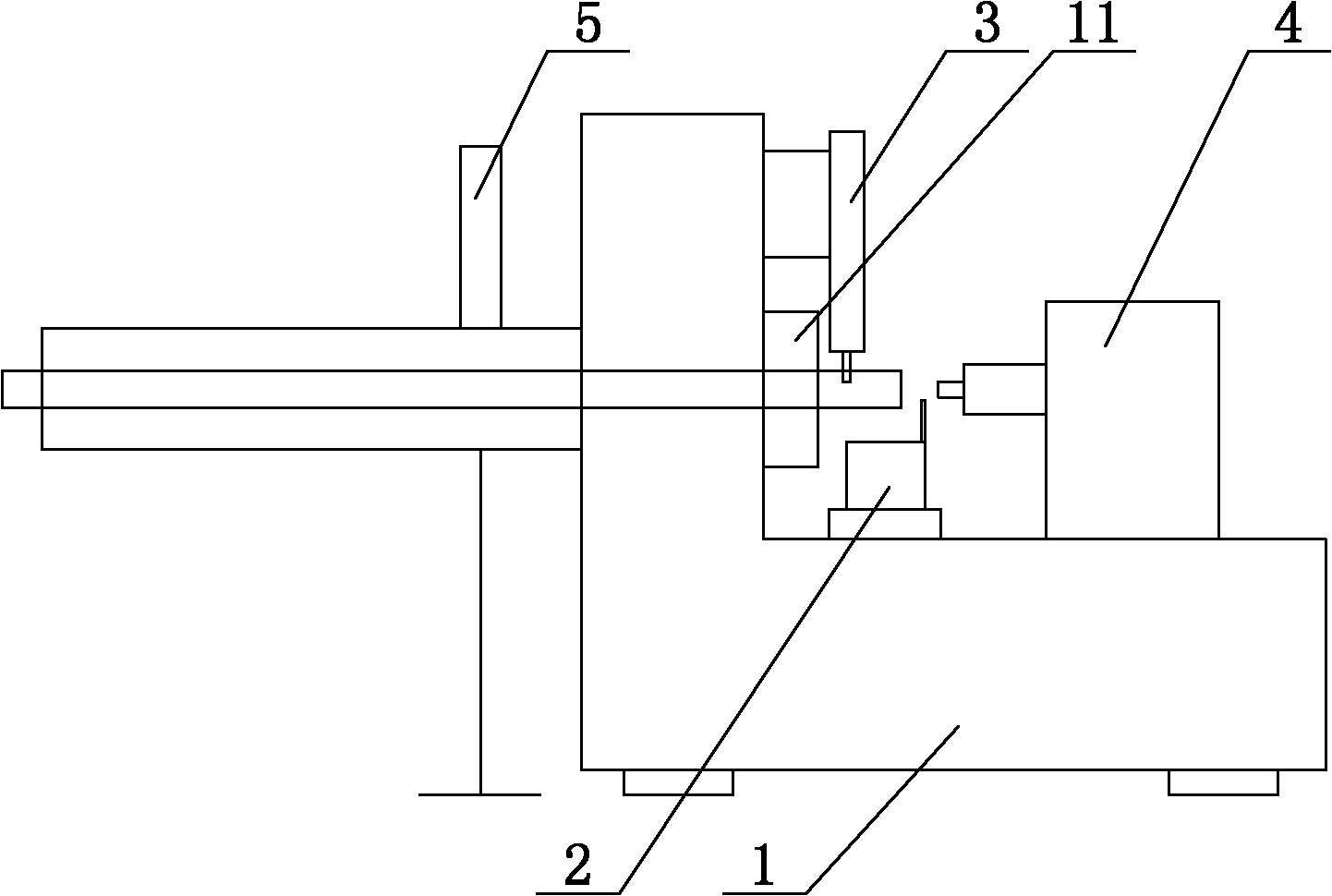

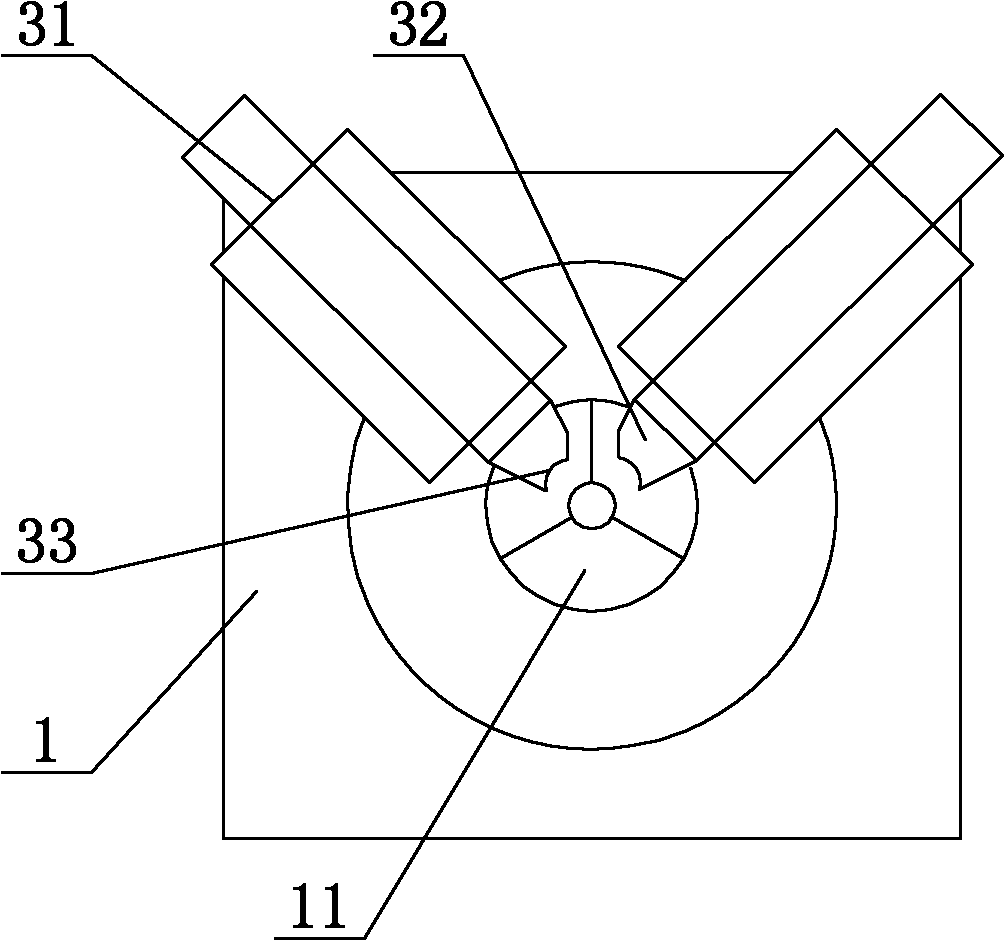

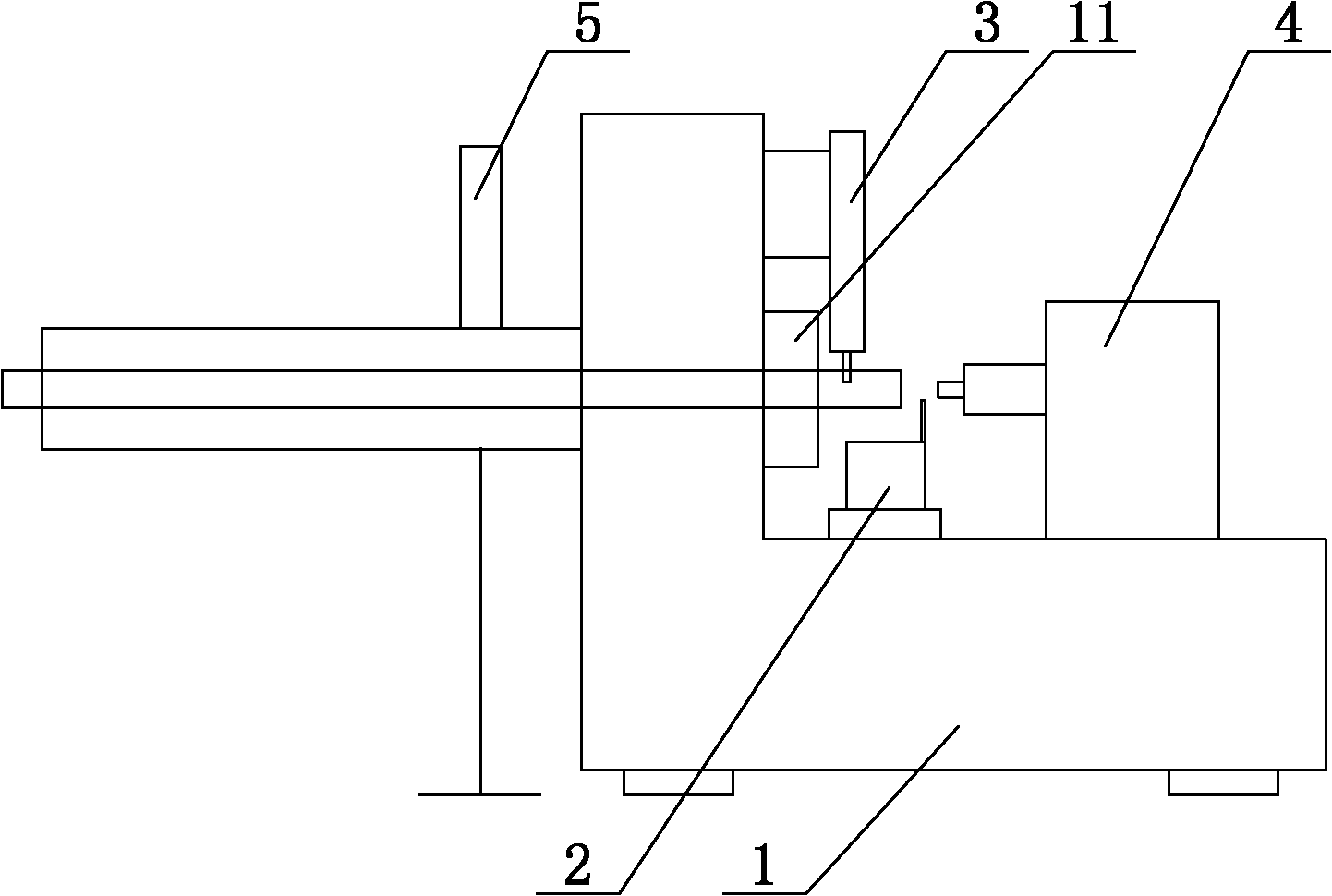

[0020] refer to figure 1 , figure 2 It is an embodiment of a valve core processing device of the present invention. A valve core processing device includes a lathe 1, and the lathe 1 is provided with a bar clamping device 11, and also includes a knife seat 2, a stamping locking device 3, The hydraulic tailstock 4, the tool holder 2 and the hydraulic tailstock 4 are all slidably arranged on the guide rail at the right part of the lathe 1, and the stamping locking device 3 is arranged at the right end of the bar material clamping device 11 on the lathe 1. The stamping locking device 3 includes two hydraulic cylinders 31, the front section of the hydraulic cylinder 31 is provided with a locking head 32 for locking the bar, and the front end of the locking head 32 is provided with an arc-shaped Groove 33, the included angles between the two hydraulic cylinders 31 and the horizontal plane are respectively 45 degrees and 135 degrees, and the tool holder 2 is provided with at least...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com