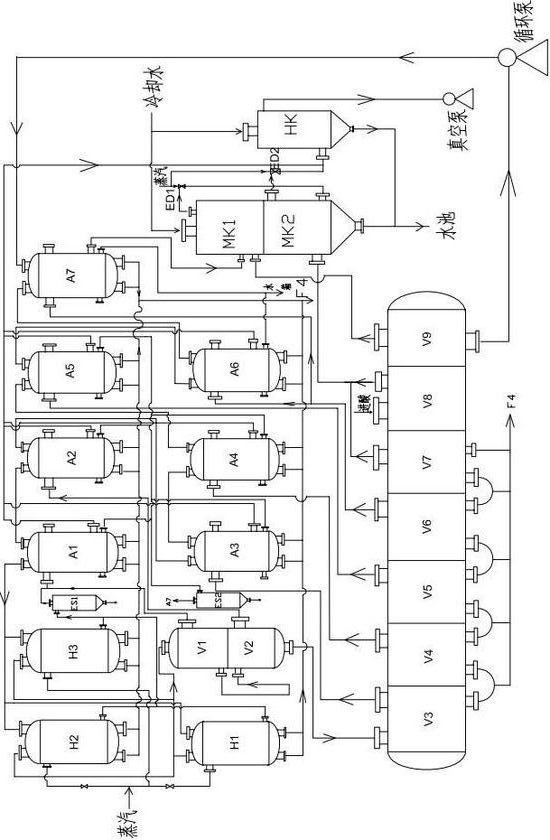

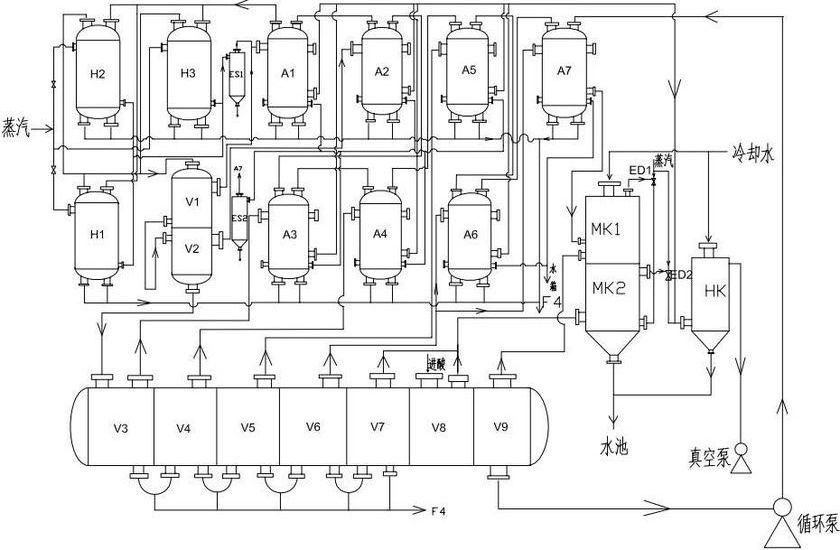

Multistage evaporating process in viscose production

A viscose fiber and stage evaporation technology, which is applied in evaporation, chemical instruments and methods, separation methods, etc., can solve the problems of heat loss and no better utilization, and achieve the effects of increasing temperature difference, improving efficiency, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A, acid bath heating: acid bath from the evaporation chamber V 8 enters, in the evaporation chamber V 8 and V 9 After evaporation and degassing in the medium, the temperature of the acid bath drops to 43°C, and the 3 / h into the preheater A 7 , and then through the preheater A 6 、A 5 、A 4 、A 3 、A 2 、A 1 , the temperature of the acid bath was preheated to 85°C, and then passed through the heater H 1 、H 2 Heating to 107°C; H 1 、H 2 Also equipped with a backup heater H 3 ;

[0034] B. Acid bath evaporation: the acid bath from the heater enters the pre-evaporation chamber V 1 , and then through the evaporation chamber V 2 , V 3 , V 4 , V 5 , V 6 , V 7 step-down evaporation, at V 7 Chamber acid bath temperature drops to 46°C, using potential difference from V 7 Out of the acid, it enters the lower tank of the acid bath;

[0035] C. Secondary steam recycling and discharge: in the secondary steam evaporated from each evaporation chamber, V 1 , V 2 , V ...

Embodiment 2

[0041] A, acid bath heating: acid bath from the evaporation chamber V 8 enters, in the evaporation chamber V 8 and V 9 After evaporating and degassing in the middle, the temperature of the acid bath drops to 46°C, and the temperature of the acid bath is reduced to 80m through the circulation pump. 3 / h into the preheater A 7 , and then through the preheater A 6 、A 5 、A 4 、A 3 、A 2 、A 1 , the temperature of the acid bath was preheated to 89°C, and then passed through the heater H 1 、H 2 Heating to 120°C; H 1 、H 2 Also equipped with a backup heater H 3 ;

[0042] B. Acid bath evaporation: the acid bath from the heater enters the pre-evaporation chamber V 1 , and then through the evaporation chamber V 2 , V 3 , V 4 , V 5 , V 6 , V 7 step-down evaporation, at V 7 The temperature of the chamber acid bath drops to 50°C, using the potential difference from V 7 Out of the acid, it enters the lower tank of the acid bath;

[0043] C. Secondary steam recycling and ...

Embodiment 3

[0049] A, acid bath heating: acid bath from the evaporation chamber V 8 enters, in the evaporation chamber V 8 and V 9 After evaporation and degassing in the medium, the temperature of the acid bath drops to 44°C, and the 3 / h into the preheater A 7 , and then through the preheater A 6 、A 5 、A 4 、A 3 、A 2 、A 1 , the temperature of the acid bath was preheated to 87°C, and then passed through the heater H 1 、H 2 Heating to 110°C; H 1 、H 2 Also equipped with a backup heater H 3 ;

[0050] B. Acid bath evaporation: the acid bath from the heater enters the pre-evaporation chamber V 1 , and then through the evaporation chamber V 2 , V 3 , V 4 , V 5 , V 6 , V 7 step-down evaporation, at V 7 Chamber acid bath temperature drops to 48°C, using potential difference from V 7 Out of the acid, it enters the lower tank of the acid bath;

[0051] C. Secondary steam recycling and discharge: in the secondary steam evaporated from each evaporation chamber, V 1 , V 2 , V ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com