Composite premix for cows

A compound premix and dairy cow technology, applied in animal feed, animal feed, additional food elements, etc., can solve the problems of shortage, low degradation rate of straw, high incidence of disease, etc., to improve health, improve nutritional balance, Morbidity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

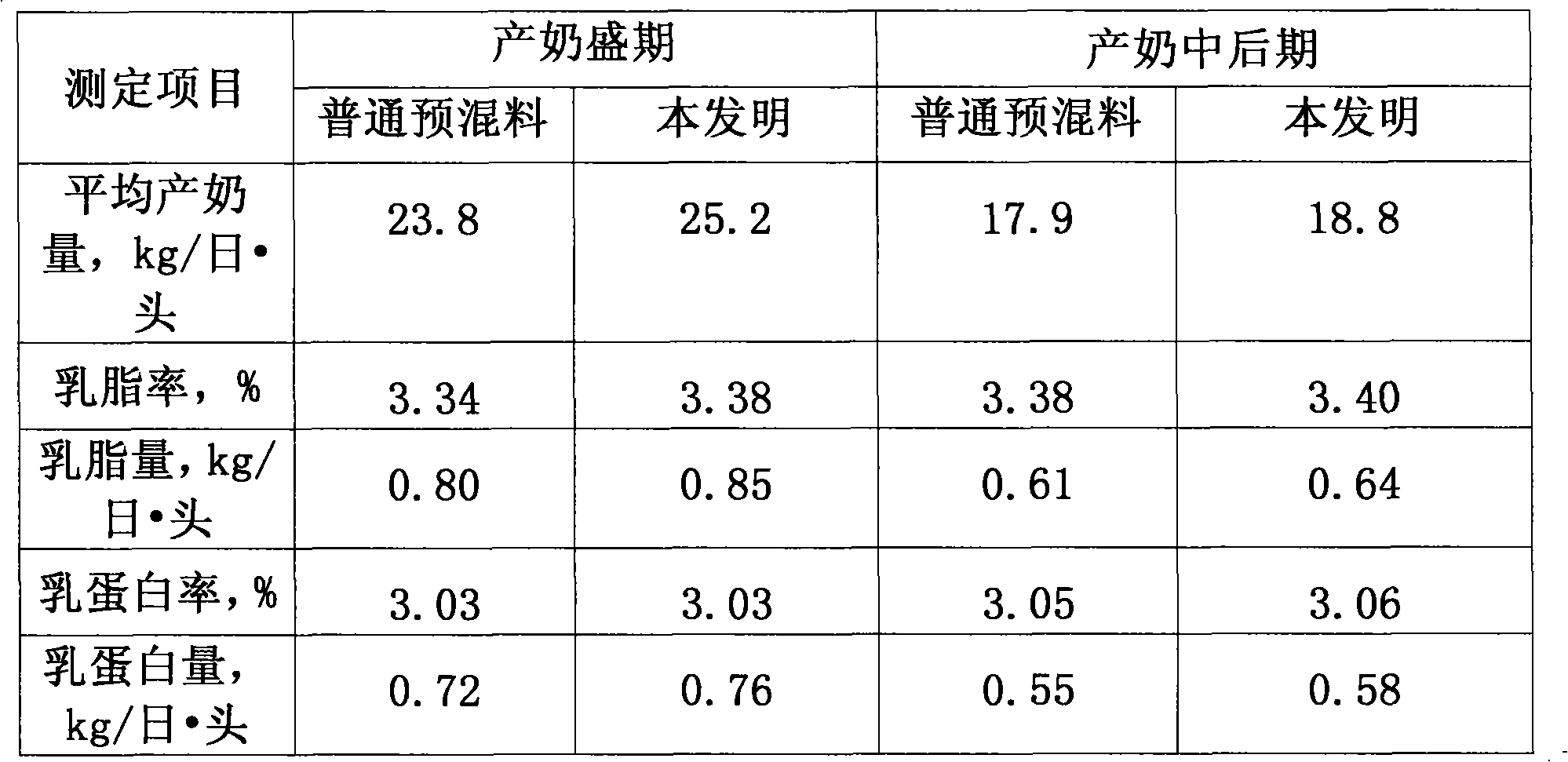

Image

Examples

Embodiment 1

[0014] Embodiment 1: stone powder 30%, copper sulfate 0.16%, manganese sulfate 0.40%, purity is 1% sodium selenite 0.16%, zinc sulfate 0.46%, purity is 1% calcium iodate 0.45%, purity is 5% Cobalt Chloride 0.12%, Magnesium Oxide 6.0%, Vitamin A 0.038%, Vitamin D 3 0.012%, vitamin E 0.1%, zeolite powder 28.1%, fine bran 20%, yeast culture 12%, dairy cow special compound enzyme 2%.

Embodiment 2

[0015] Embodiment 2: stone powder 20%, copper sulfate 0.12%, manganese sulfate 0.20%, purity is 1% sodium selenite 0.12%, zinc sulfate 0.40%, purity is 1% calcium iodate 0.5%, purity is 5% Cobalt Chloride 0.1%, Magnesium Oxide 7.0%, Vitamin A 0.036%, Vitamin D 3 0.014%, vitamin E 0.12%, zeolite powder 30%, fine bran 30%, yeast culture 10%, dairy cow special compound enzyme 1.39%.

Embodiment 3

[0016] Embodiment 3: stone powder 29.4%, copper sulfate 0.14%, manganese sulfate 0.30%, purity is 1% sodium selenite 0.14%, zinc sulfate 0.44%, purity is 1% calcium iodate 0.3%, purity is 5% Cobalt Chloride 0.11%, Magnesium Oxide 8.0%, Vitamin A 0.04%, Vitamin D 3 0.016%, vitamin E 0.114%, zeolite powder 20%, fine bran 29%, yeast culture 11%, dairy cow special compound enzyme 1%.

[0017] 1g of milk cow special compound enzyme contains 12000μ of cellulase, 80000μ of xylanase and 22000μ of β-glucanase.

[0018] The yeast culture of the present invention is Danongwei Yikang XP produced by Danongwei Biological Fermentation Engineering Technology (Shenzhen) Co., Ltd. Yeast accounts for less than 5% of the composition of Danon Weiyikang XP, while more than 95% of the composition is a mixture of extracellular metabolites and variant media.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com