Encapsulating process of solar cell module

A technology of solar cells and packaging technology, applied in electrical components, circuits, photovoltaic power generation, etc., can solve problems such as high fragmentation rate, low efficiency, and easy extrusion of battery components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

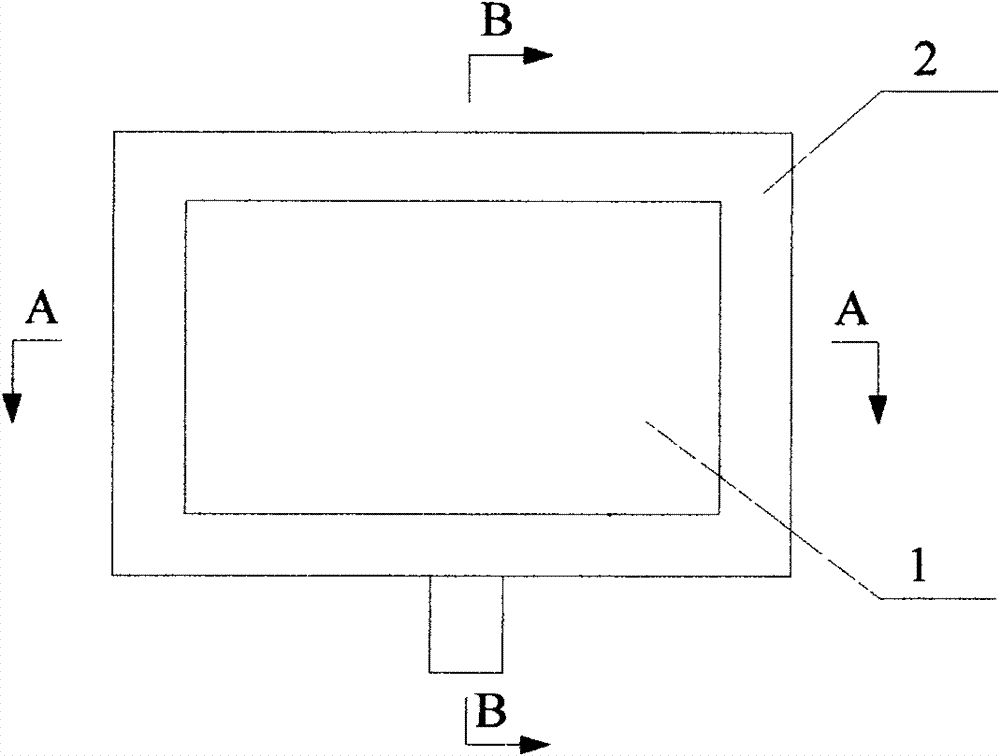

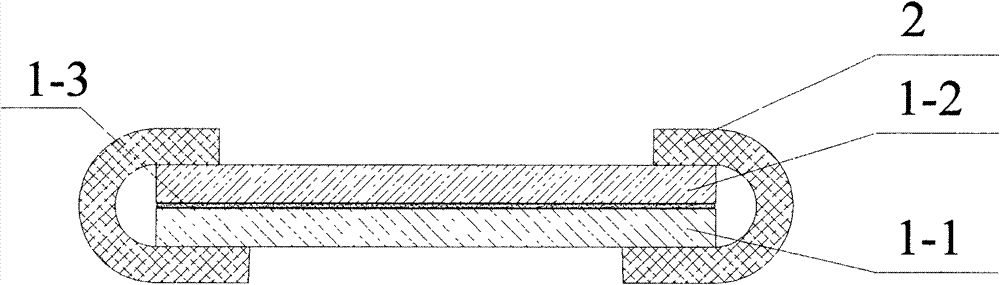

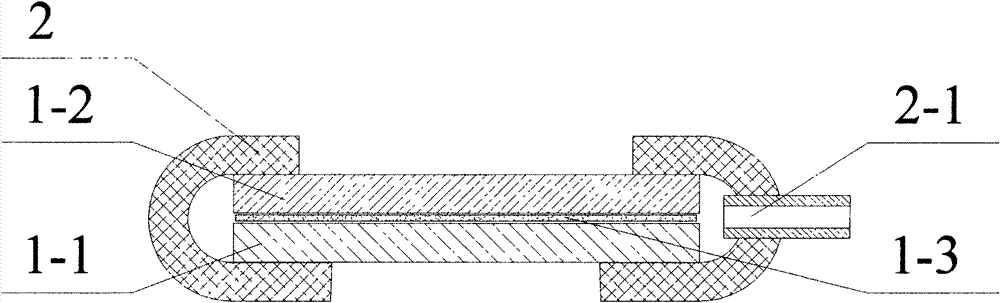

[0022] A packaging process for a solar cell module, the steps of the above packaging process include performing composite processing on the substrate substrate storage 1-1 storage, insulating film storage 1-3 storage, and packaging substrate storage 1-2 storage for the prepared solar cell layer Solar cell module storage 1 storage, and then solar cell module storage 1 storage for sizing treatment and installation of junction boxes. The above-mentioned sizing treatment process is to realize the external environment atmosphere of solar cell module storage 1 storage by means of an autoclave, and with the help of a supporting vacuum system Realize the internal environment atmosphere of the solar cell module storage 1 storage, and further set the process conditions with the help of the temperature and pressure control system. The solar cell module storage 1 storage is stored in the kettle to complete the heating, pressurization and shaping process simultaneously. The specific steps in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com