Iron core structure with permanent magnet materials for auxiliary excitation

A technology of permanent magnet material and auxiliary excitation, applied in the field of iron core structure, can solve the problems of waste of excitation ampere-turn, increase of DC winding requirements, increase of equipment volume, weight and production cost, and achieve the effect of reducing production cost and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

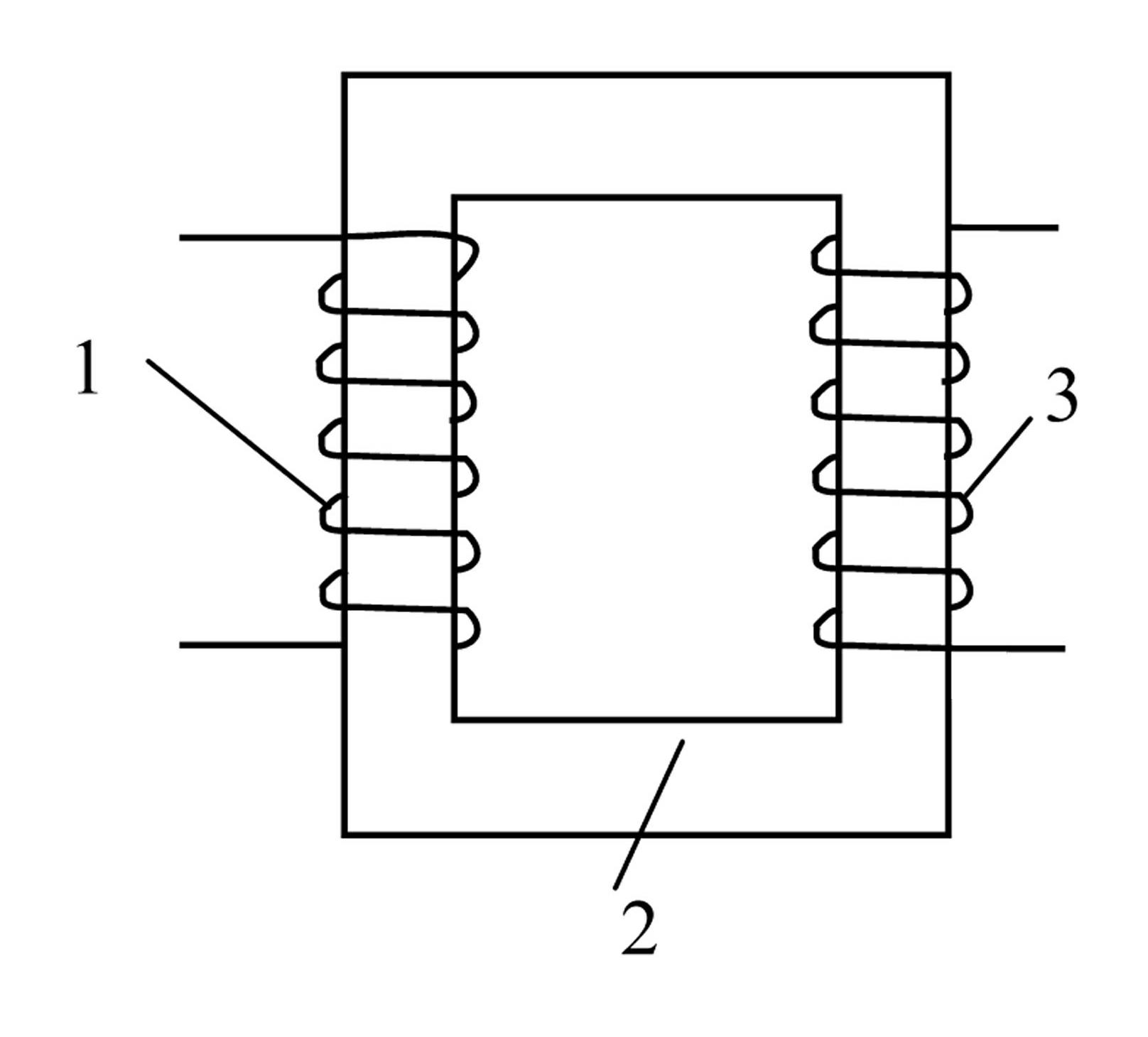

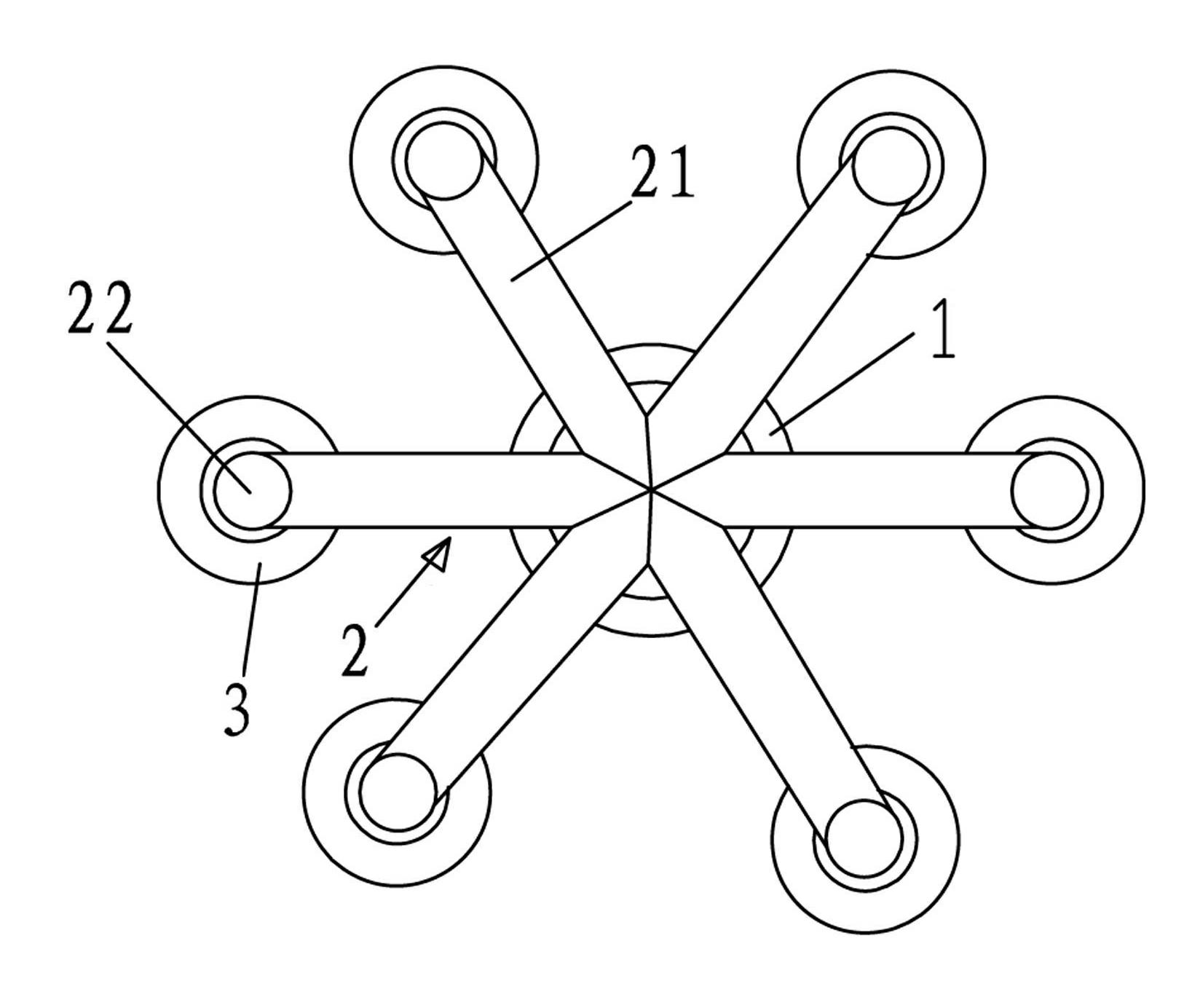

[0027] In the present invention, the iron core with permanent magnet material auxiliary excitation is a square iron core or other similar shape iron core, which can be a single iron core (see figure 1 ) or a combination of several iron cores (see figure 2 , each core has a central core column 21 and a side column 22) structure. The DC winding 1 and the AC winding 3 are respectively located on the pillars of different iron cores of the same iron core window 2, which is a loosely coupled structure.

[0028] For this type of loosely coupled structure, the excitation magnetic potential generated by the DC winding should be effectively transferred to the AC side core column, and make it reach the required saturation level. The structural characteristics of loose coupling and the magnetic flux leakage will increase greatly when the core is saturated, so that without other auxiliary excitation means, it is necessary to increase the DC excitation ampere-turn and / or increase the cros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com