Aerated detector of damper of oil seal type

A shock absorber and detection machine technology, applied in the direction of shock absorber, inflation gas pressure measurement, shock absorber, etc., can solve the problems of high waste rate of gas source, low qualified rate, inconvenient maintenance, etc., and achieve accurate inflation , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

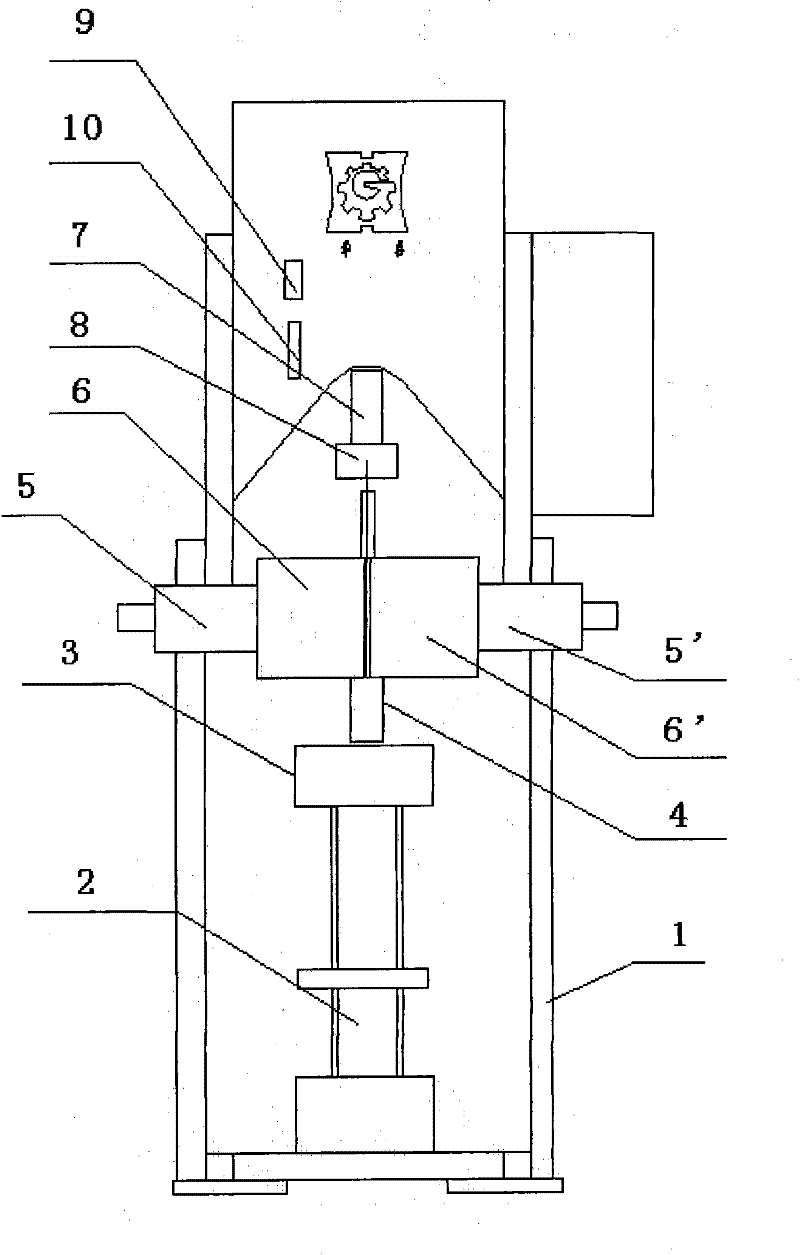

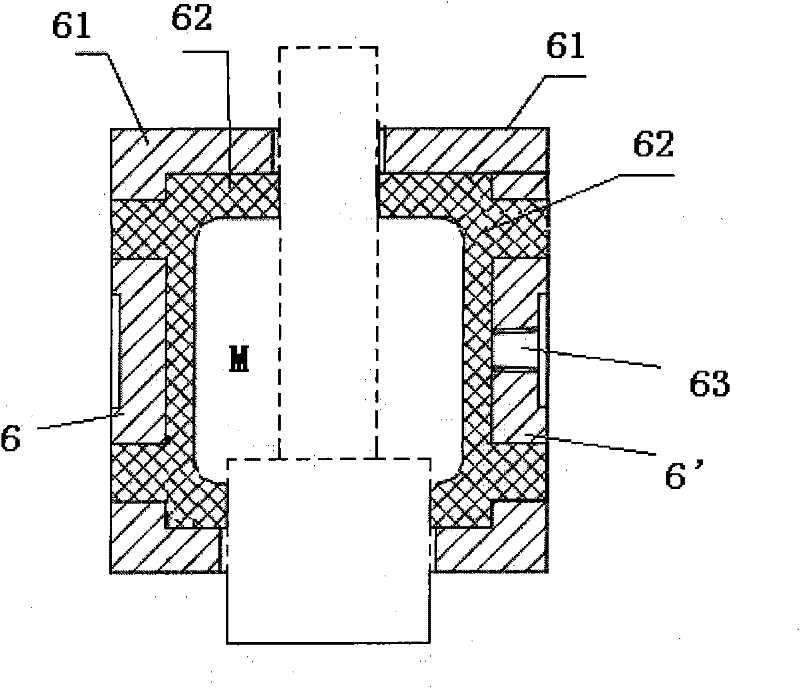

[0017] Such as figure 1 As shown, the present invention adopts hydraulic and pneumatic drive technology to clamp the shock absorber, so that the air-filled part of the shock absorber forms a closed air chamber, and the gas is filled into the shock absorber air storage chamber through the air needle. At this time, the shock absorber The connecting rod is in compression. Then loosen the shock absorber to make the connecting rod pop up. Under the reverse resistance of the air force detection device arranged above, the popping up of the connecting rod is hindered and cannot be completely popped up, so as to measure the rebuttal force value after inflation.

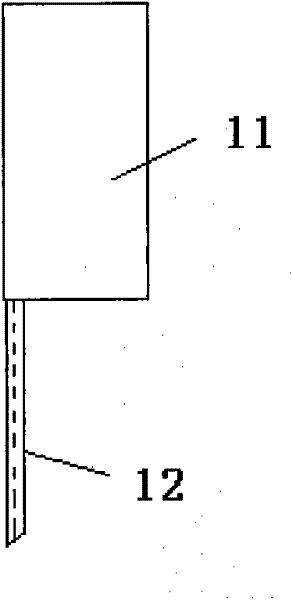

[0018] Specifically, it includes a main frame 1, and a hand-operated screw 2 is arranged at the bottom of the main frame. The upper end of the hand-operated screw 1 has a mold seat 3, and the mold se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com