Preparation process and equipment of powder metallurgic multicomponent rare-earth alloy giant-magnetostrictive material

A giant magnetostrictive and rare-earth alloy technology, which is applied in the direction of material selection for magnetostrictive devices, manufacture/assembly of magnetostrictive devices, manufacture/assembly of piezoelectric/electrostrictive devices, etc., can solve the cost Problems such as high difficulty to drop, unloadability, and high material brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

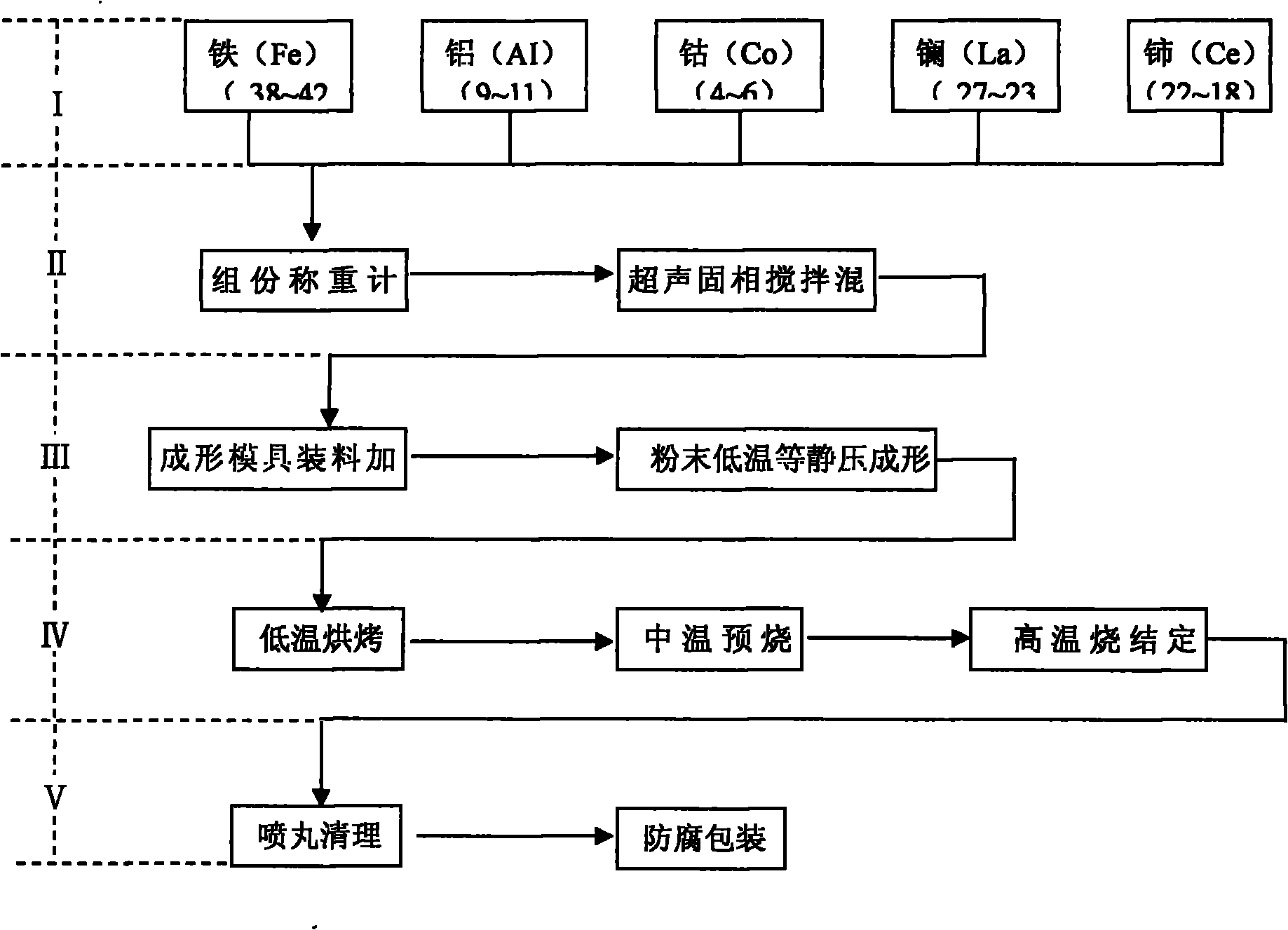

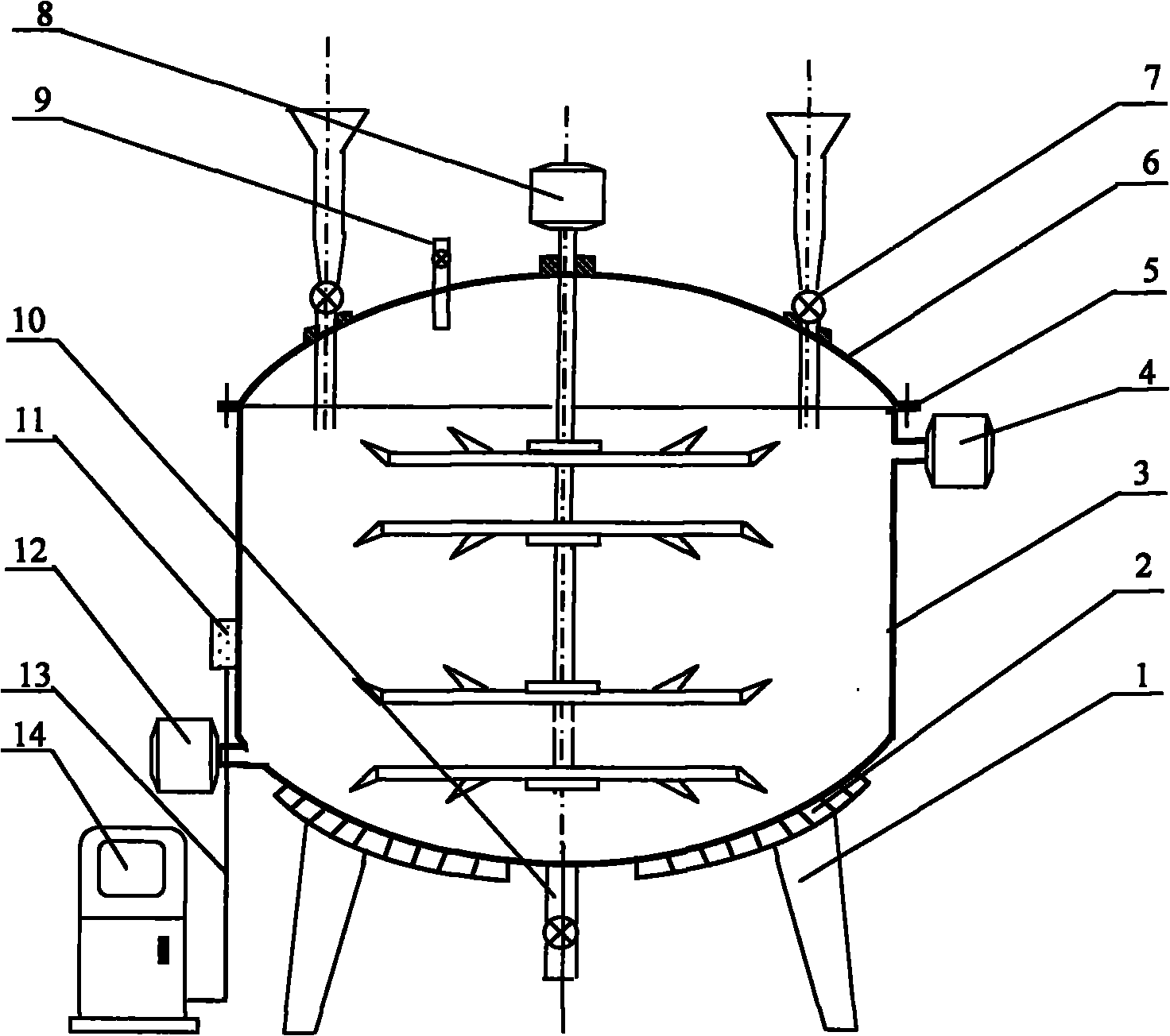

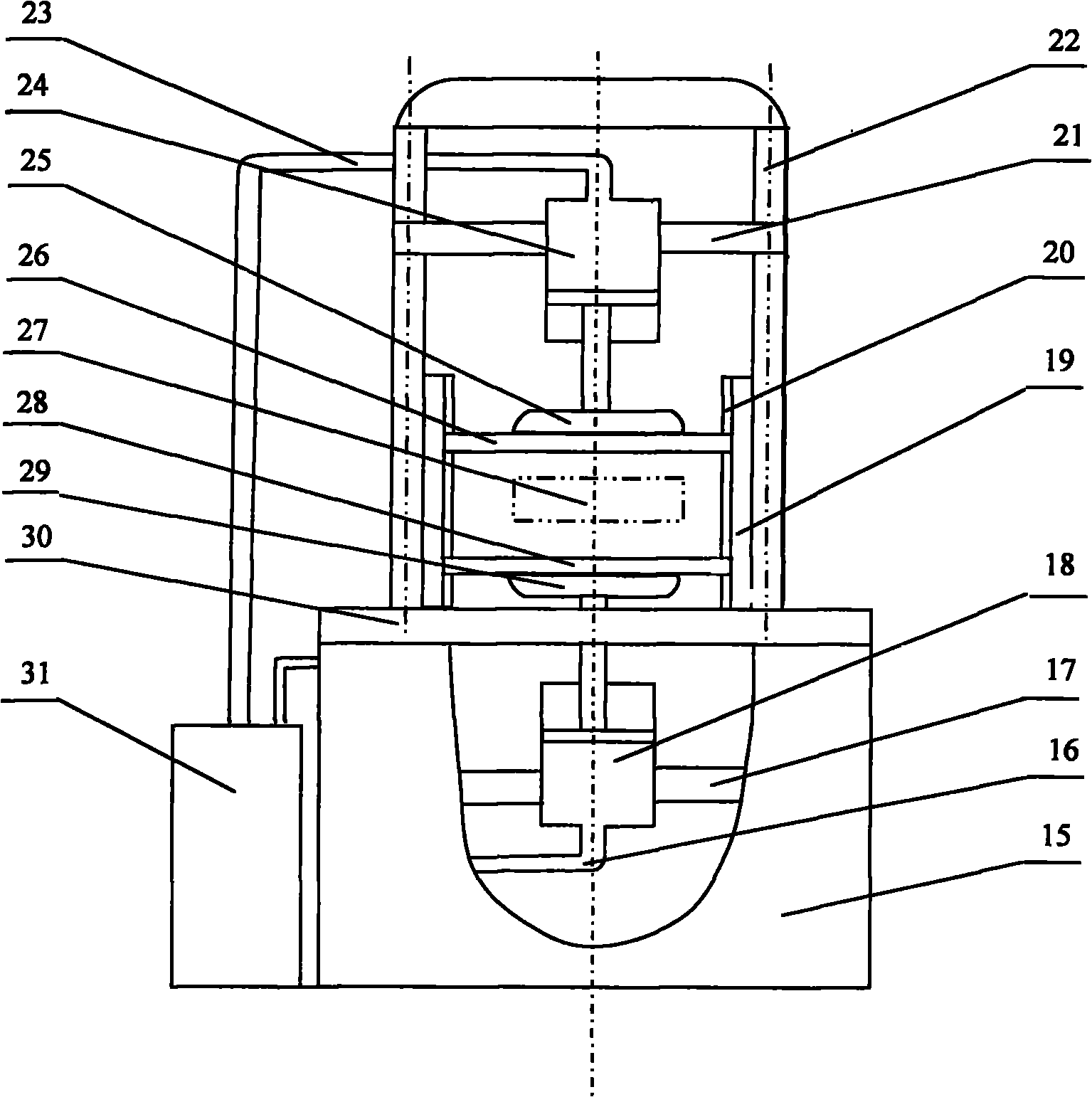

[0086] As shown in Figure 1, the preparation process and equipment of the powder-metallurgy multi-element rare earth alloy giant magnetostrictive material of the present invention include multi-element component ratio, ultrasonic solid-phase stirring and mixing, low-temperature isostatic pressing of powder, successive sintering and shaping, and product cleaning Packaging and other 5 relatively independent process technology units.

[0087] As shown in accompanying drawing 1, the described multi-component material proportioning process technology unit is based on the excellent characteristics of single material, abundant resources, low price, easy purification and manufacture, and can interact and compensate each other after combination and combination, so as to obtain the best The composition ratio principle of good magnetostrictive effect and good mechanical and physical properties is based on the existing widely used metal magnetostrictive materials, which are mixed with a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com