Design method for automatic high-pressure water cleaning device

A technology of automatic cleaning and design method, applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of short processing gap, time-consuming and laborious, unable to clean, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

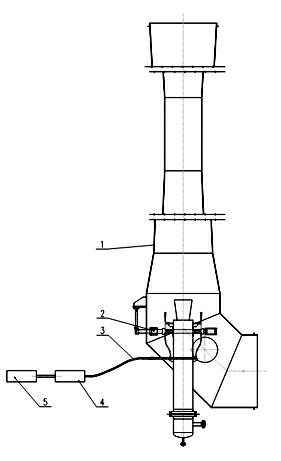

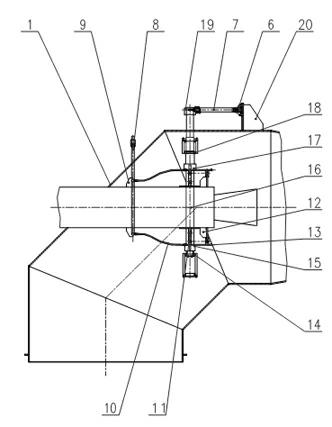

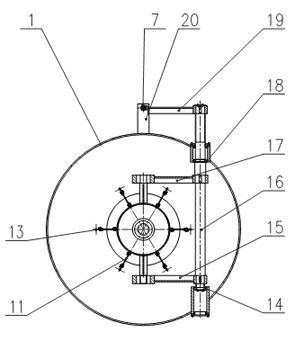

[0015] In the embodiment, this high-pressure water automatic cleaning device includes a hydraulic cylinder base 6, a hydraulic cylinder 7, a high-pressure water pipeline 8, a pipeline fixing frame 9, a hose set 10, an adjusting connecting rod 11, a high-pressure nozzle fixing frame 12, a high-pressure Nozzle 13, bearing one 14, swing arm one 15, rotating shaft 16; swing arm two 17, bearing two 18, swing arm three 19, hydraulic cylinder support 20; it is characterized in that: the pressure of high pressure water pump 5 connection and pressure transmitter 21 The input end is connected, and connected with the connecting hose 3 and the high-pressure water pipe 8 through the solenoid valve 4, the high-pressure water pipe 8 is fixed on the pump body 1 through the pipe fixing frame 9, and the high-pressure water pipe 8 is connected with the high-pressure nozzle 13 through the hose group 10 , the high-pressure nozzle 13 is rotationally connected with one end of the adjustment connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com