Process for smelting ferronickel from red soil nickel ore

A technology of laterite nickel ore and ferronickel, which is applied in the field of smelting ferronickel from laterite nickel ore, to achieve the effects of reducing the process of pouring cans, reducing energy consumption, and simplifying process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

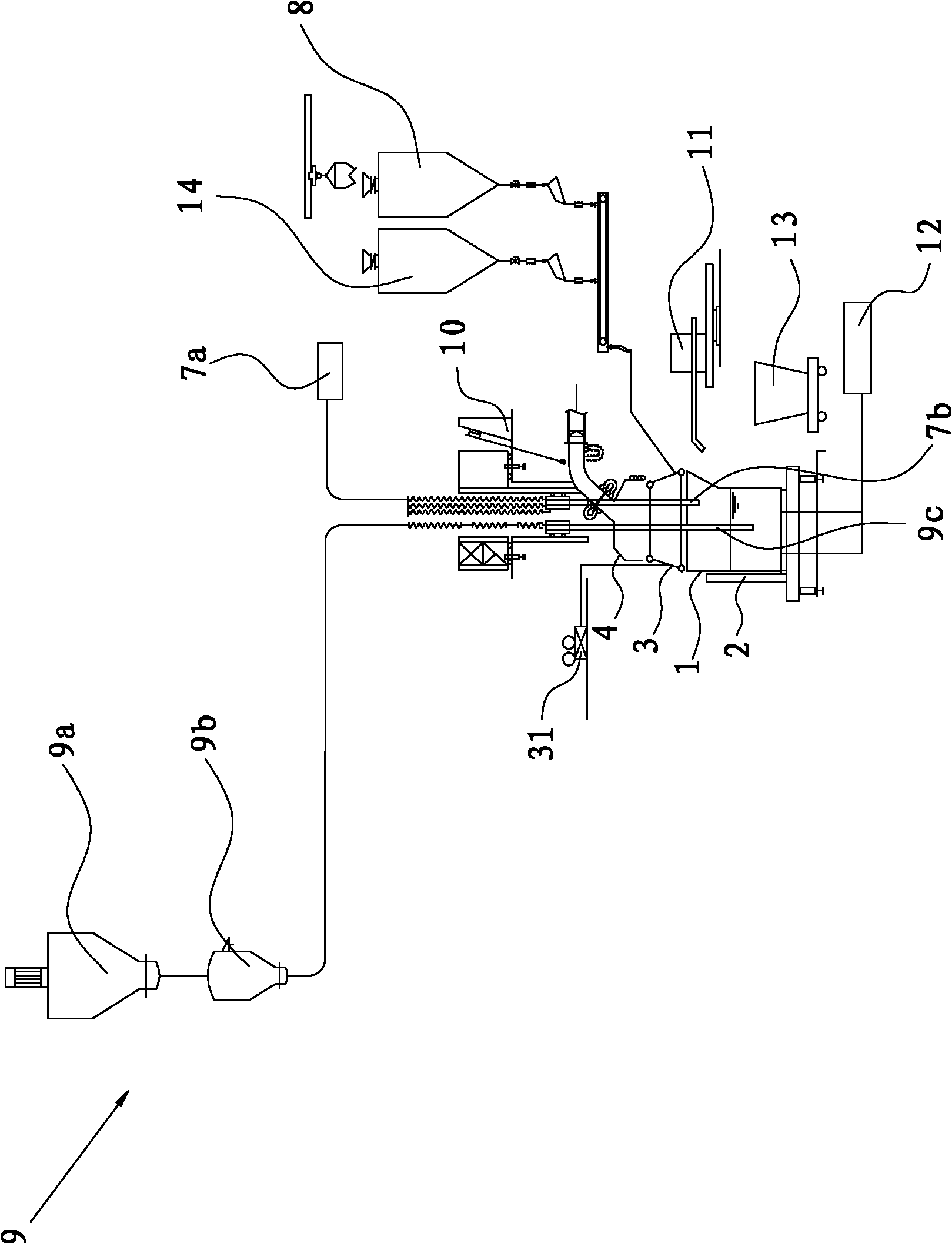

Image

Examples

Embodiment 1

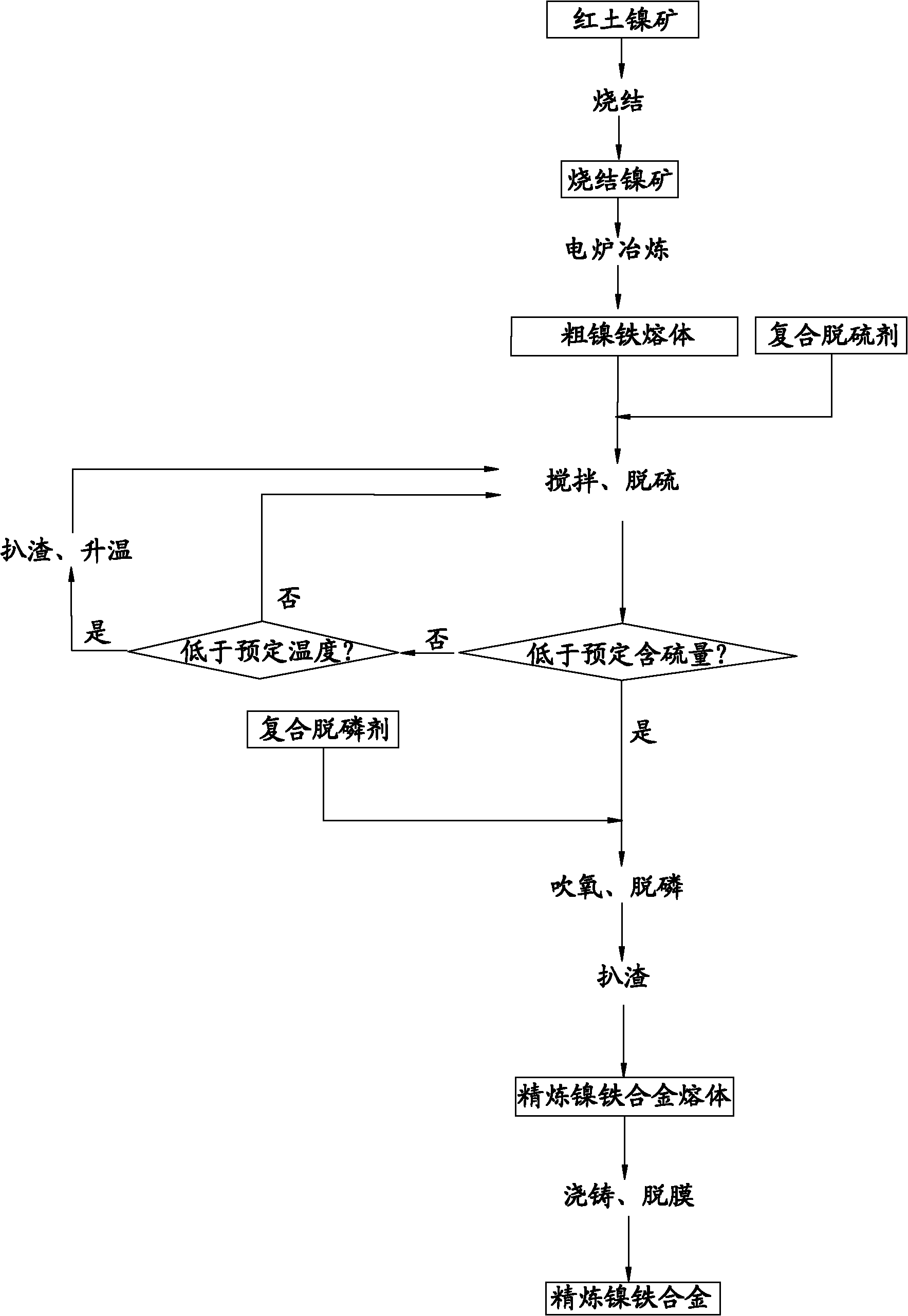

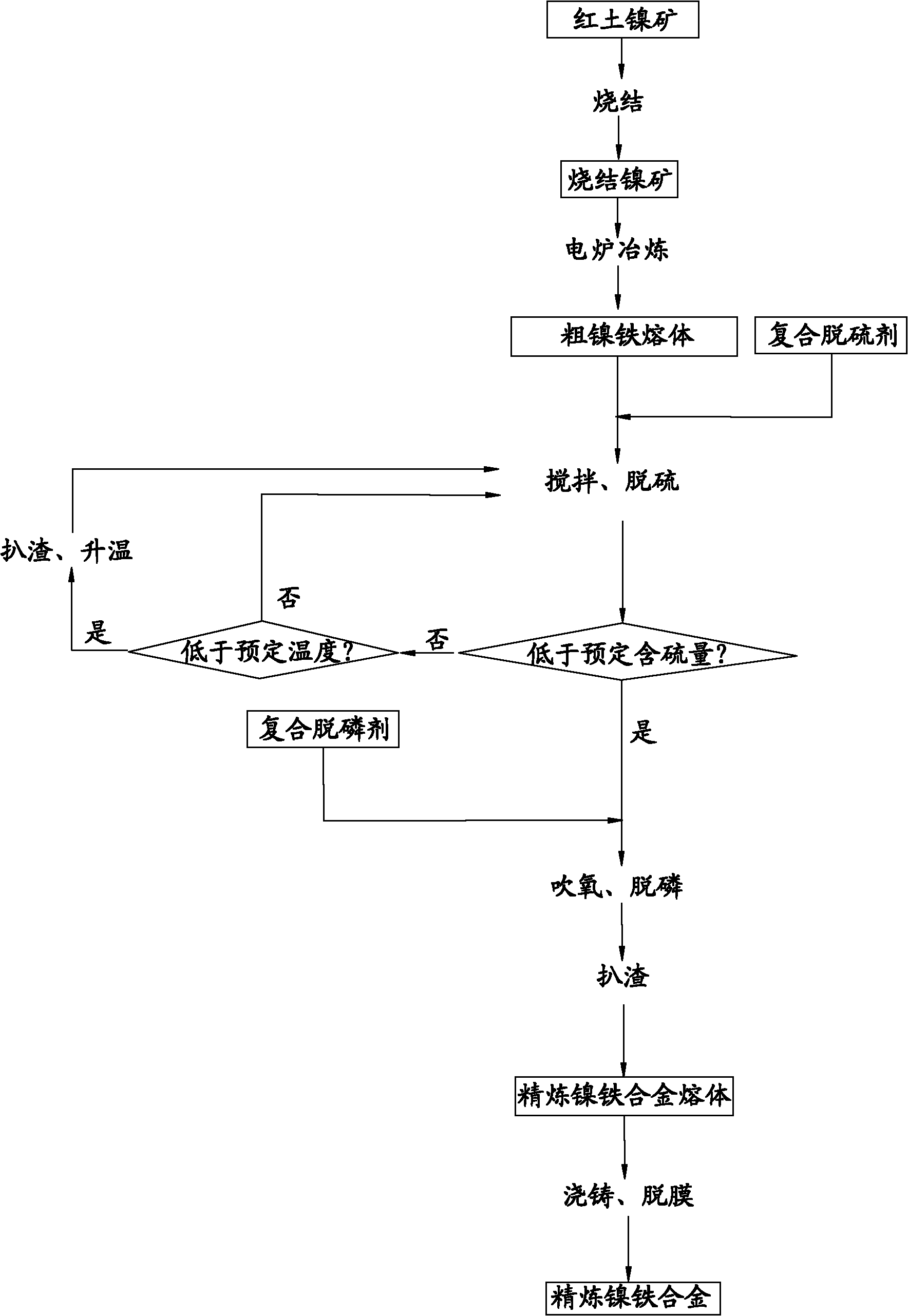

[0055] Reference below figure 2 Describe the process of smelting ferronickel from laterite nickel ore according to Example 1 of the present invention, figure 1 The schematic flow chart of the process for smelting ferronickel from laterite nickel ore according to the first embodiment is shown.

[0056] Step 1: The laterite nickel ore is mixed with coal powder or coke in a weight ratio of 90:10 to 95:5, and then a rotary kiln is used for sintering at 600 to 1000°C for 2 to 8 hours to obtain sintered nickel ore.

[0057] For example, laterite nickel ore and coal powder or coke powder are mixed in a weight ratio of 90:10, and then sintered at 800° C. for 5 hours using a rotary kiln to obtain sintered nickel ore.

[0058] Step 2: After that, put the sintered nickel ore, flux and reducing agent into an electric furnace for smelting at 200V to 300V for 1 to 3 hours to obtain crude nickel iron.

[0059] Step 3: Then, the high-sulfur crude ferronickel produced by the electric furnace is poure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com