Offshore natural gas liquefying method and device

A technology of natural gas and nitrogen, which is applied in the field of offshore natural gas liquefaction methods and liquefaction devices, can solve problems such as LNG-FPSO liquefaction devices that have not yet appeared, and achieve the effects of solving offshore applicability, reducing production costs, and reducing device valves

Inactive Publication Date: 2011-06-15

CHINA NAT OFFSHORE OIL CORP +2

View PDF3 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

As one of the cores of LNG-FPSO, the design of the liquefaction device will have a great impact on the infrastructure cost, operating cost, operation reliability and safety of the project, but there is no liquefaction device applied to LNG-FPSO

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

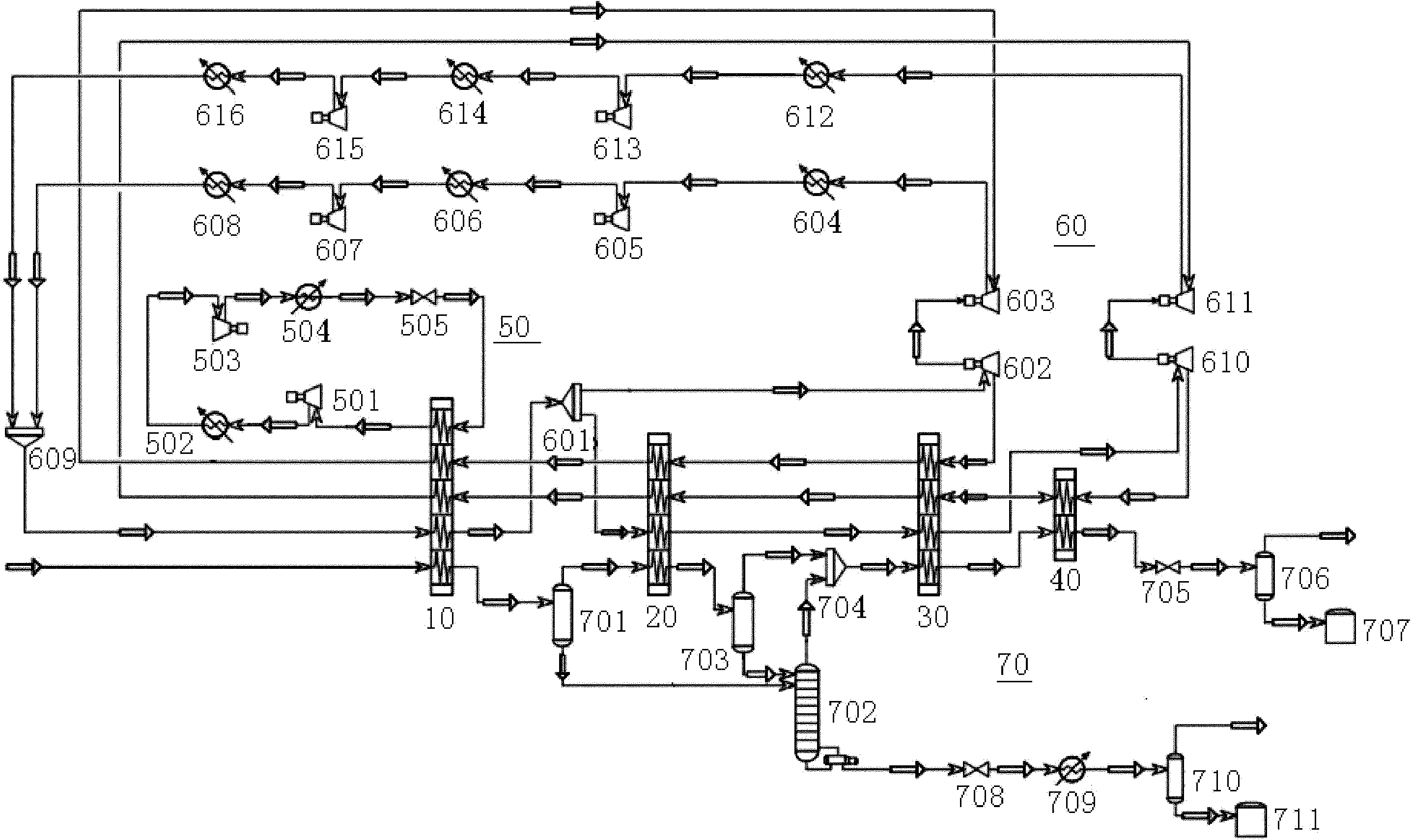

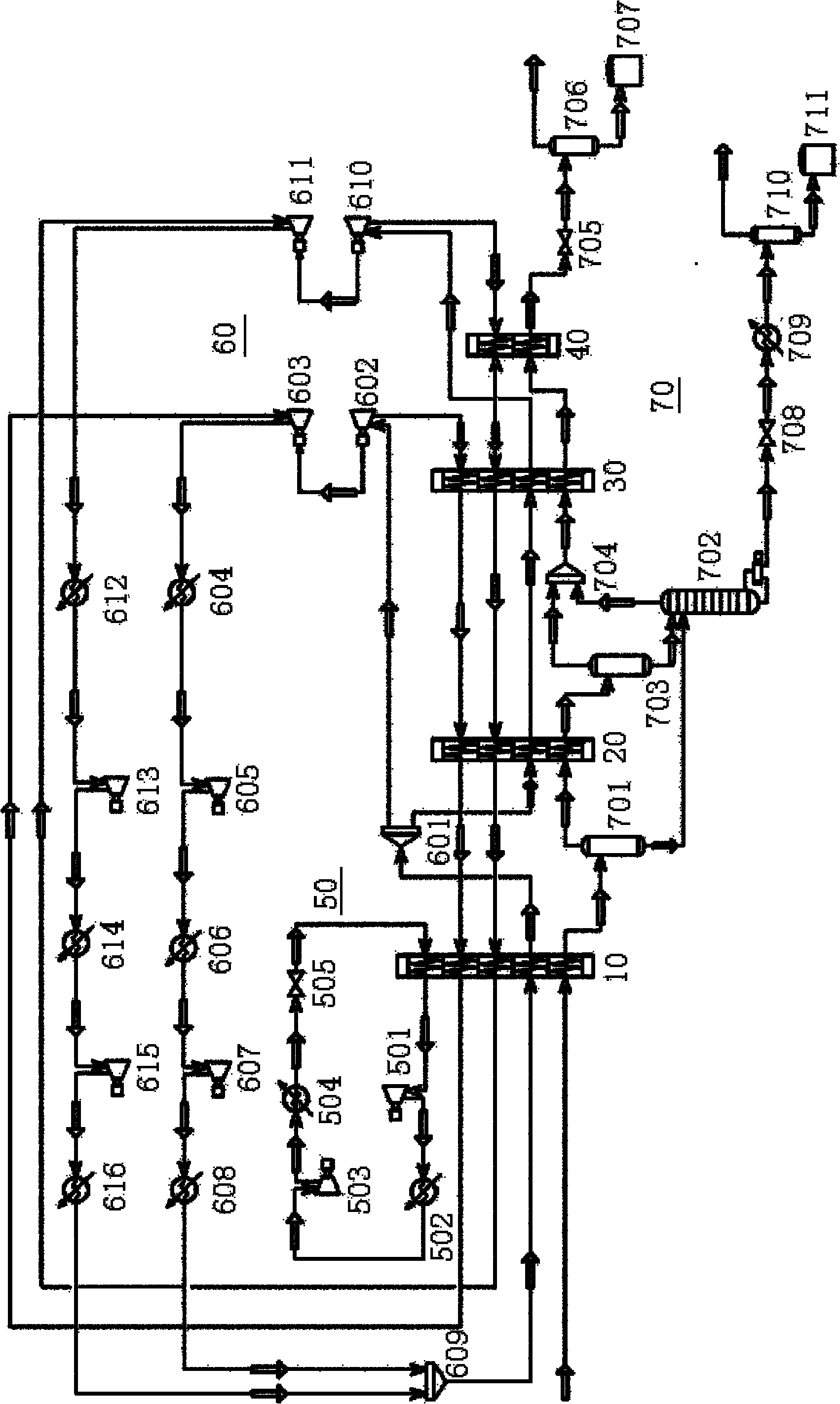

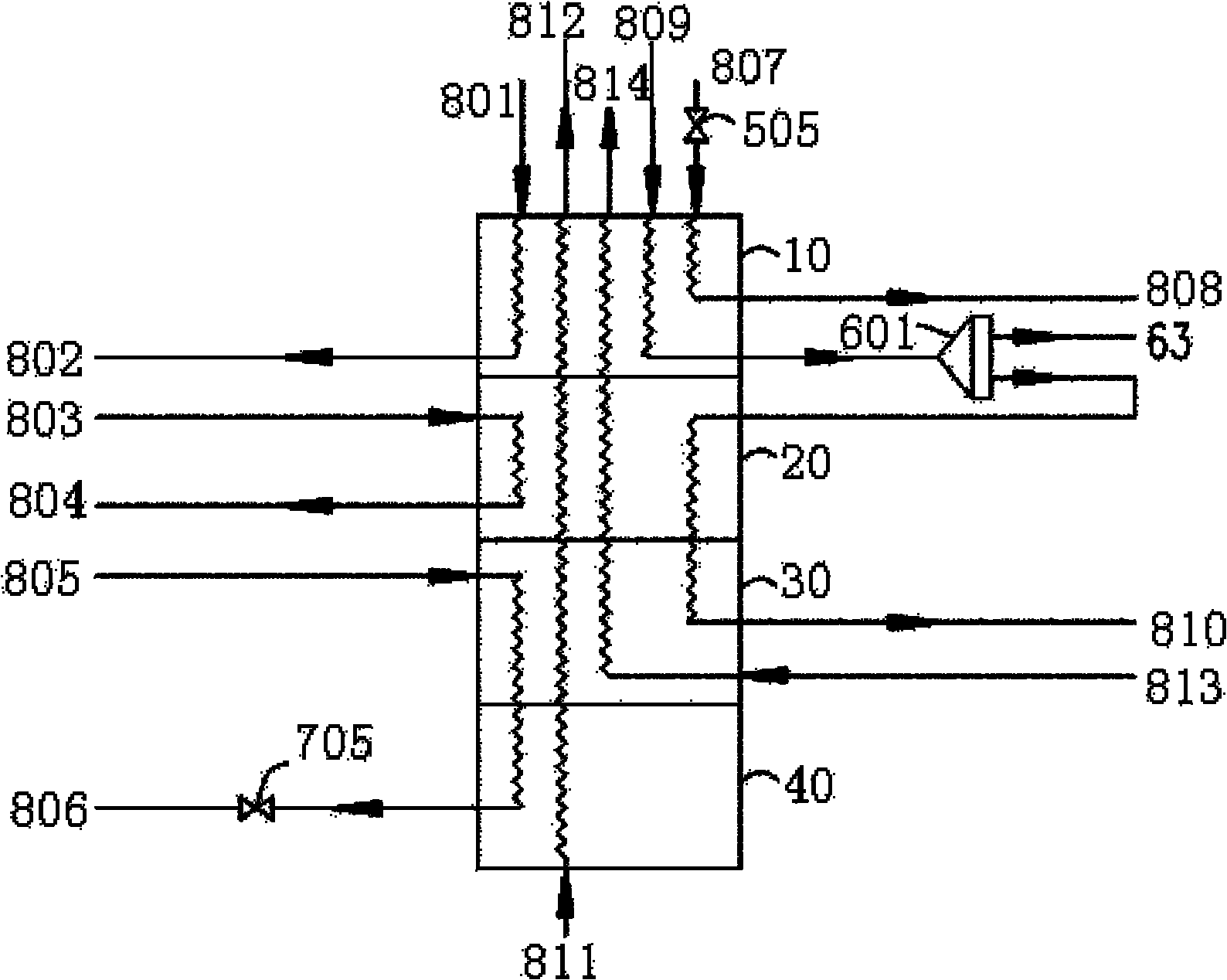

The invention relates to an offshore natural gas liquefying method and an offshore natural gas liquefying device. The method comprises the following steps of: 1) pretreating natural gas extracted from seabed, and inputting into a heat exchange cold box; 2) continuously reducing pressure and temperature of preset carbon dioxide gas in a carbon dioxide pre-cooling circulating system, and introducing the carbon dioxide gas into the heat exchange cold box; 3) compressing preset nitrogen in a double nitrogen expansion refrigeration circulating system into high pressure nitrogen, introducing the high pressure nitrogen into the heat exchange cold box, precooling by carbon dioxide, directly reducing pressure and temperature of one path of nitrogen by using an expander, continuously precooling the other path of nitrogen and reducing pressure and temperature by using the expander, returning the two path of low pressure nitrogen to the heat exchange cold box, exchanging heat, raising the temperature, lifting the pressure, reducing the temperature, and returning to the heat exchange cold box; and 4) precooling the pretreated natural gas by using the carbon dioxide gas in the heat exchange cold box, introducing into a heavy hydrocarbon separation unit, gradually cooling the natural gas by the returned nitrogen, removing the heavy hydrocarbon by using a gas-liquid separator and a rectifying column, cooling, throttling and reducing temperature by using a throttle valve, introducing a gas-liquid mixture into a buffer tank, introducing a liquid phase into a storage tank for storage, discharging a gas phase from the top of the buffer tank and collecting the gas phase.

Description

Offshore natural gas liquefaction method and liquefaction device technical field The invention relates to a production method and a production device of liquefied natural gas (LNG, Liquefied Natural Gas), in particular to an offshore natural gas liquefaction method and a liquefaction device. Background technique my country's offshore natural gas resources are abundant, with a total geological resource of about 5.9 trillion cubic meters. However, these natural gas resources are scattered and distributed in the Pearl River Mouth Basin, Yinggehai Basin, Qiongdongnan Basin, East China Sea Shelf Basin and Bohai Bay Basin, and among them Quite a few are deep sea gas fields, small marginal gas fields and low-grade natural gas resources. For these gas sources, if traditional offshore fixed platforms or submarine pipelines are used, most gas fields cannot be put into production due to cost or technical limitations. If LNG-FPSO (Liquefied Natural Gas-Floating Production Storage & O...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C10L3/10F25B1/00

Inventor 谢彬李玉星喻西崇王春升王武昌朱建鲁刘永浩谢文会郑晓鹏

Owner CHINA NAT OFFSHORE OIL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com