Lotus leaf surface-imitated super-hydrophobic film and preparation method thereof

A super-hydrophobic, imitation lotus leaf technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems that limit the wide application of micro/nano coatings, the inability to form large-scale films, and the complicated preparation process, and achieve stable storage Good performance, low cost and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

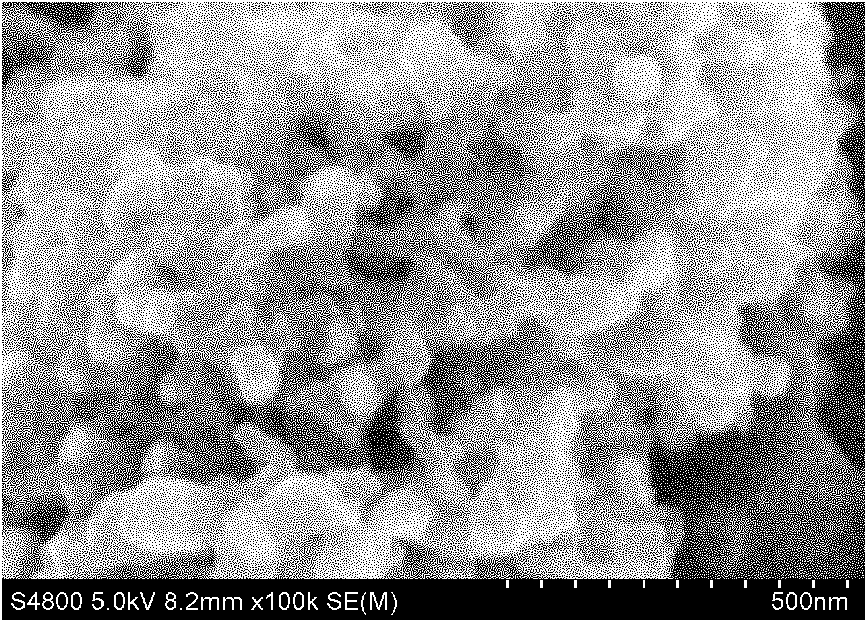

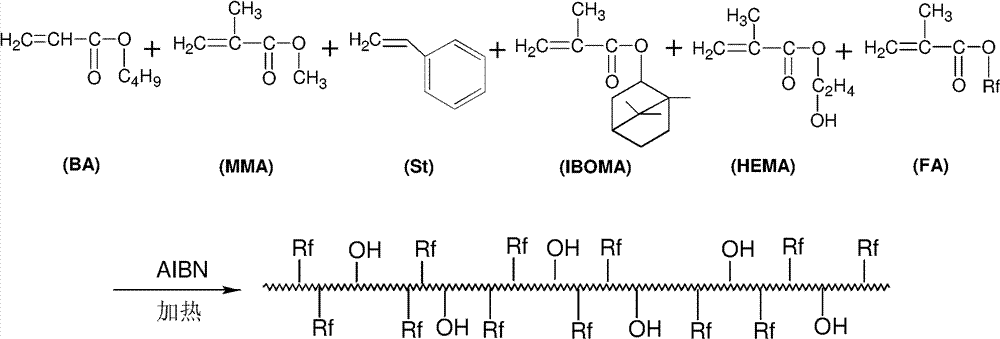

[0022] Kind of like figure 1 The superhydrophobic film imitating the surface of the lotus leaf of the present invention is shown, and the superhydrophobic film includes a base film made of low surface energy material and a micro / nano structure formed on the base film. The base film is a composite of organic fluorine modified acrylate and organic silicon modified polyurethane. The micro / nano structure includes micron-sized particles uniformly distributed on the base film (the average particle size of the micron-sized particles in this embodiment is about 3 μm, see figure 1 ) And the nanoscale papillae grown on the micron-scale particles (the average particle size of the nanoscale papillae in this example is about 40nm, see figure 1 ), the micron-sized particles and nano-sized papillae are made of modified Fe 3 O 4 Aggregated by nanoparticles. In the superhydrophobic film imitating the surface of the lotus leaf of this embodiment, the modified Fe 3 O 4 The mass ratio of nanopartic...

Embodiment 2

[0038] A super-hydrophobic film imitating the surface of a lotus leaf of the present invention. The super-hydrophobic film comprises a base film made of low surface energy material and a micro / nano structure formed on the base film. The base film is a composite of organic fluorine modified acrylate and organic silicon modified polyurethane. The micro / nano structure includes uniformly distributed micron-sized particles (average particle size around 5μm) on the base film and nano-sized papillae (average particle size around 40nm) grown on the micron-scale particles, the micron-scale particles and Nanoscale papillae are made of modified SiO 2 Aggregated by nanoparticles. In the super-hydrophobic film on the surface of the lotus leaf of this embodiment, the modified SiO 2 The mass ratio of nanoparticles to base film is 0.1:1.

[0039] The superhydrophobic film imitating the surface of the lotus leaf of this embodiment is specifically prepared by the following steps:

[0040] (1) Prep...

Embodiment 3

[0047] A super-hydrophobic film imitating the surface of a lotus leaf of the present invention. The super-hydrophobic film comprises a base film made of low surface energy material and a micro / nano structure formed on the base film. The base film is a composite of organic fluorine modified acrylate and organic silicon modified polyurethane. The micro / nano structure includes uniformly distributed micron-sized particles (average particle size around 5μm) on the base film and nano-scale papillae (average particle size around 40nm) grown on the micron-scale particles. The micron-scale particles and Nanoscale papillae are made of modified TiO 2 Aggregated by nanoparticles. In the super-hydrophobic film imitating the surface of the lotus leaf of this embodiment, the modified TiO 2 The mass ratio of nanoparticles to base film is 0.2:1.

[0048] The super-hydrophobic film imitating the surface of the lotus leaf of this embodiment is specifically prepared by the following steps:

[0049] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com