Circuit board and manufacture method thereof

A manufacturing method and circuit board technology, applied in the direction of multilayer circuit manufacturing, printed circuit components, electrical components, etc., can solve problems such as electromagnetic interference and serious noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

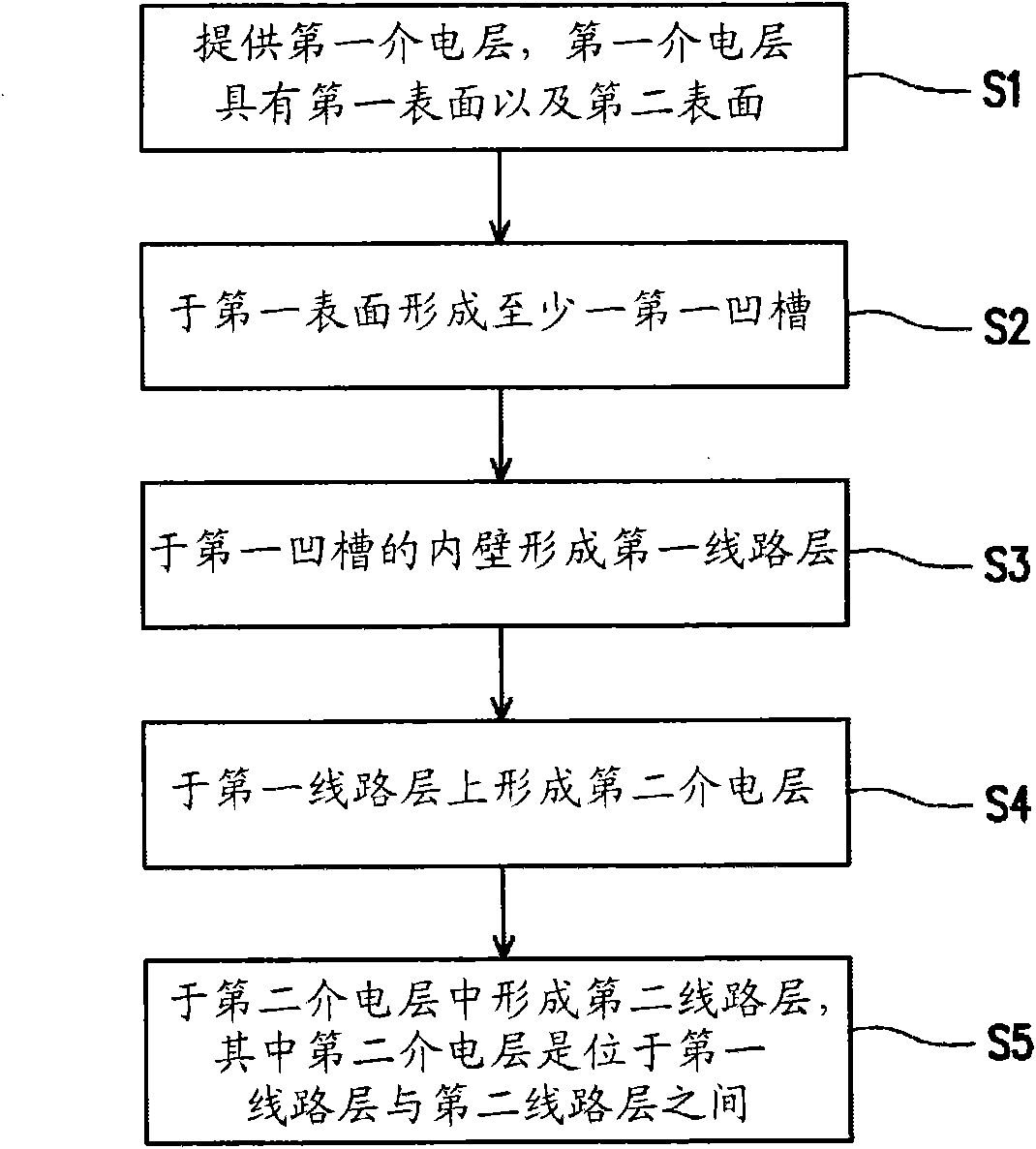

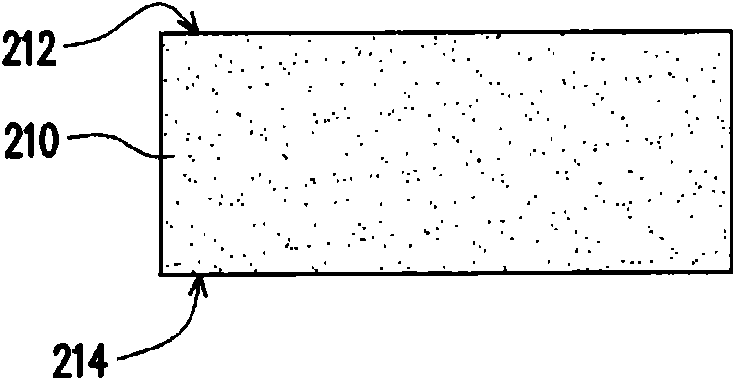

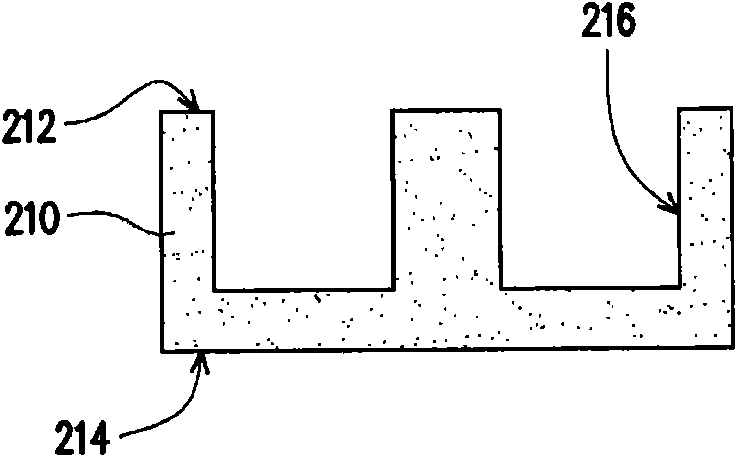

[0025] figure 1 A flow chart of manufacturing a circuit board according to an embodiment of the present invention is shown. Please refer to figure 1 , in this embodiment, the manufacturing method of the circuit board includes the following steps: First, as shown in step S1, a first dielectric layer is provided, and the first dielectric layer has a first surface and a second surface. Then, as shown in step S2, at least one first groove is formed on the first surface. Next, as shown in step S3, a first circuit layer is formed on the inner wall of the first groove. Next, as shown in step S4, a second dielectric layer is formed on the first circuit layer. After that, as shown in step S5 , a second circuit layer is formed in the second dielectric layer, wherein the second dielectric layer is located between the first circuit layer and the second circuit layer.

[0026] In order to understand the manufacturing method of the circuit board of this embodiment in more detail, this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com