Synthesis method of imidazoline compound

A synthesis method and compound technology, applied in chemical instruments and methods, chemical/physical processes, organic chemistry, etc., can solve problems such as opacity, precipitation, and turbidity of imidazoline surfactant aqueous solution, and meet the requirements of production equipment. The effect of low production cost and stable quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

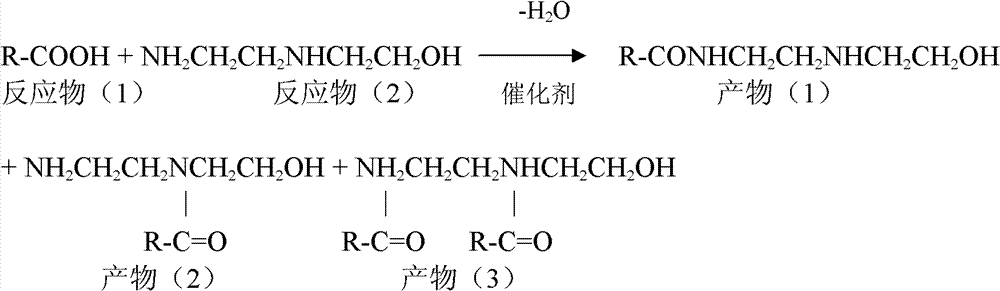

Method used

Image

Examples

Embodiment 1

[0031] In a 1-liter four-neck flask equipped with mechanical stirring, nitrogen inlet pipe, thermometer and vacuum distillation device, add 400 grams of lauric acid, 270.4 grams of hydroxyethylethylenediamine, and 3.4 grams of sodium hydroxide, nitrogen, and stir The temperature was raised to 130°C. Start timing and adjust the heating rate at the same time. It takes 4 hours to raise the temperature to 200° C., keep the reaction at this temperature for 1 hour, and distill off the water generated by the reaction. Start the vacuum pump, adjust the pressure of the reaction system to 5000Pa, start timing and adjust the decompression speed at the same time, and reduce the pressure of the reaction system to 101Pa in 2 hours. Under the condition of material temperature of 200° C. and reaction system pressure of 101 Pa, heat preservation reaction was carried out for 1 hour, and the water generated by the reaction and residual hydroxyethylethylenediamine were distilled off. Heating was...

Embodiment 2

[0033] In a 1-liter four-necked flask equipped with mechanical stirring, nitrogen inlet pipe, thermometer and vacuum distillation device, add 456 grams of myristic acid, 291.2 grams of hydroxyethylethylenediamine, and 3.7 grams of sodium hydroxide, and stir with nitrogen gas. Lower the temperature to 130°C. Start timing and adjust the heating rate at the same time. It takes 4 hours to raise the temperature to 200° C., keep the reaction at this temperature for 1 hour, and distill off the water generated by the reaction. Start the vacuum pump, adjust the pressure of the reaction system to 5000Pa, start timing and adjust the decompression speed at the same time, and reduce the pressure of the reaction system to 101Pa in 2 hours. Under the condition of material temperature of 200° C. and reaction system pressure of 101 Pa, heat preservation reaction was carried out for 1 hour, and the water generated by the reaction and residual hydroxyethylethylenediamine were distilled off. Hea...

Embodiment 3

[0035] In a 1 liter four-neck flask equipped with mechanical stirring, nitrogen inlet pipe, thermometer and vacuum distillation device, add 400 grams of lauric acid, 291.2 grams of hydroxyethylethylenediamine, and 5.5 grams of sodium hydroxide, nitrogen, and stir The temperature was raised to 150°C. Start timing and adjust the heating rate at the same time, heat up to 190° C. in 3 hours, keep the reaction at this temperature for 2 hours, and distill off the water generated by the reaction. Start the vacuum pump, adjust the pressure of the reaction system to 4000Pa, start timing and adjust the decompression speed, and reduce the pressure of the reaction system to 202Pa in 3 hours. Under the conditions of material temperature 190° C. and reaction system pressure 202 Pa, heat preservation reaction was carried out for 2 hours, and the water generated by the reaction and residual hydroxyethylethylenediamine were distilled off. Heating was stopped and the temperature was lowered to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com