Method and system for rapidly optimizing drawing technology of photonic crystal fiber

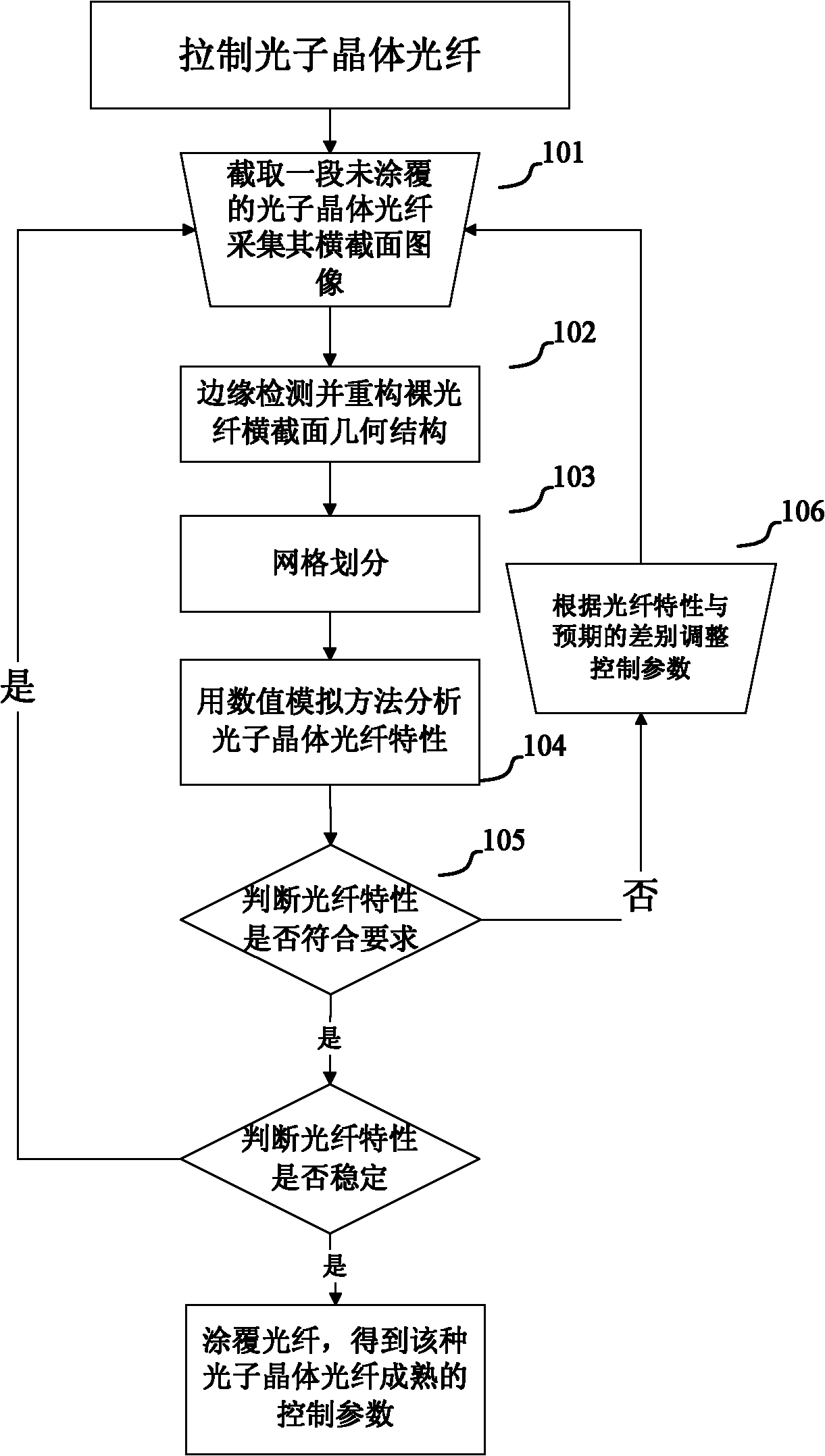

A photonic crystal fiber, rapid technology, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of inability to optimize the drawing process parameters, insufficient analysis of the slight deformation of the photonic crystal fiber, etc., to shorten the development cycle, shorten the development time, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] image 3 A schematic cross-sectional view of the design structure of the photonic crystal fiber according to Embodiment 1 of the present invention is shown. The photonic crystal fiber in Example 1 is a five-circle air hole fiber with a diameter of 125 mm made of pure silica as the background material, and its design characteristic is that only the fundamental mode can be effectively transmitted during transmission.

[0059] For example, the preform rod of the photonic crystal fiber is fabricated by the tube rod stacking method, and the diameter of the preform rod is 18 mm. One end of the preform is fixed on the feeding device of the optical fiber drawing device 1001, and the other end of the preform is heated in the heating device. The molten part of the preform in the heating device is pulled by the pulling device to form a bare optical fiber. First, process parameters are selected based on experience, for example: furnace temperature 1950°C, feeding speed 0.3mm / min,...

Embodiment 2

[0082] Figure 12 It shows a cross-sectional schematic diagram of a design structure of a dispersion-compensated photonic crystal fiber with a negative dispersion central wavelength of 1550 nm according to Embodiment 2 of the present invention, and the design requirement of the fiber is to have a large negative dispersion performance around 1550 nm. The background material of the photonic crystal fiber is, for example, pure silica, and the central region is, for example, germanium-doped silica as a high-refractive-index core. The prefabricated rod is produced by the tube rod stacking method, and the diameter of the preset rod is 18mm. During the drawing process, air is drawn from the gap between the thin tube and the thin rod, and the air is inflated into the thin tube at the same time. One end of the preform is fixed on the feeding device of the optical fiber drawing equipment, and the other end enters the heating device for heating, and the molten part of the preform is pull...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com