Manual pipe cutter

A technology of cutters and pipe fittings, applied in the field of manual pipe fittings cutters, can solve the problems of small cutting diameter range of cutters, burrs on plastic pipes, affecting the quality of knots, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

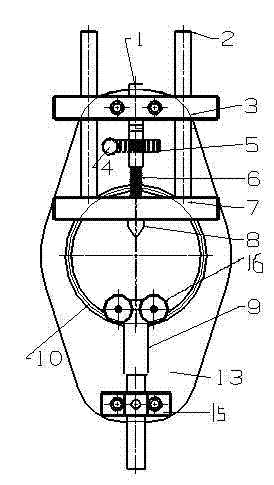

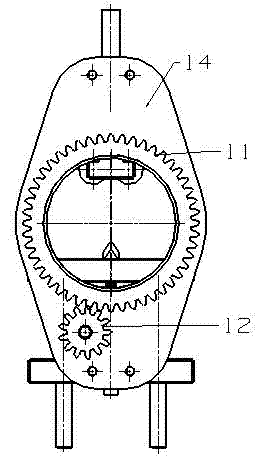

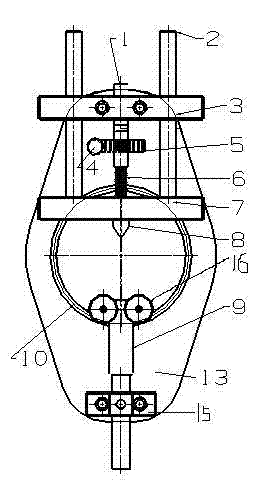

[0012] Such as figure 1 As shown, the manual pipe cutter includes a cutting disc 13, a clamping disc 14, a center wheel 11, a planetary wheel 12, a worm 4, a worm gear 5, a screw 6, a feed shaft 1, a knife rest 7 and a blade 8, the cutting disc 13 and Clamping disc 14 is installed on the outer wall of sleeve 10 respectively by its central circular hole, and clamping disc 14 is fixed on the bottom of sleeve 10, and center wheel 11 is installed on the outer wall of sleeve 10, and center wheel 11 is positioned at cutting disc 13 and Between the clamping discs 14, the center wheel 11 is fixed on the clamping disc 14, and the cutting disc 13 is located on the top of the sleeve 10 above the center wheel 11 and can rotate concentrically. The wheel 12 meshes with the center wheel 11, and the worm 4 is fixedly installed above the cutting disc 13. The bottom of the worm 4 passes through the cutting disc 13 and connects to the planetary wheel 12. The guide plate 3 is installed on the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com