Sedimentation type soil-liquid separator

A solid-liquid separation and sedimentation technology, which is applied to the feeding/discharging device of the settling tank, the use of liquid separating agent, the settling tank, etc., can solve problems such as disturbance and lowering the settling separation efficiency of the solid-liquid separation device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

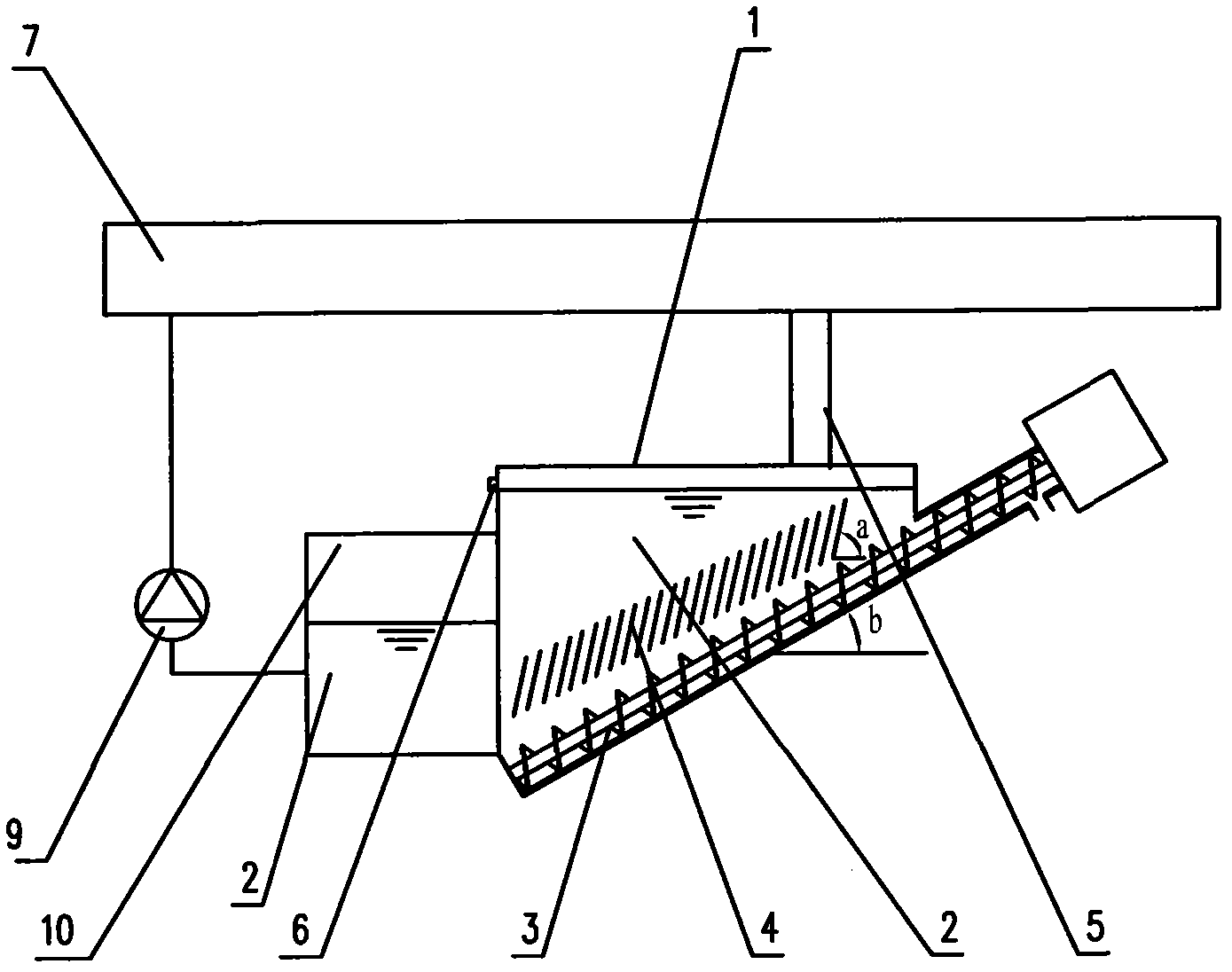

[0048] Such as figure 1 Shown is the settling type solid-liquid separation device described in this embodiment, comprising: a settling water tank 1, a liquid inlet tank is arranged on the top of the settling water tank 1, and the width of the liquid inlet tank is the width of the settling water tank 1 0.8 times the width;

[0049] A liquid outlet is provided on one side of the settling water tank 1 and near the top;

[0050] A circulating water tank 10 is also provided on the side where the settling water tank is provided with a liquid outlet, and the adsorption liquid flowing out from the liquid outlet 6 enters the circulating water tank 10, and the circulating water tank 10 passes through a circulating pump and a wet dust collector. 7-phase connection;

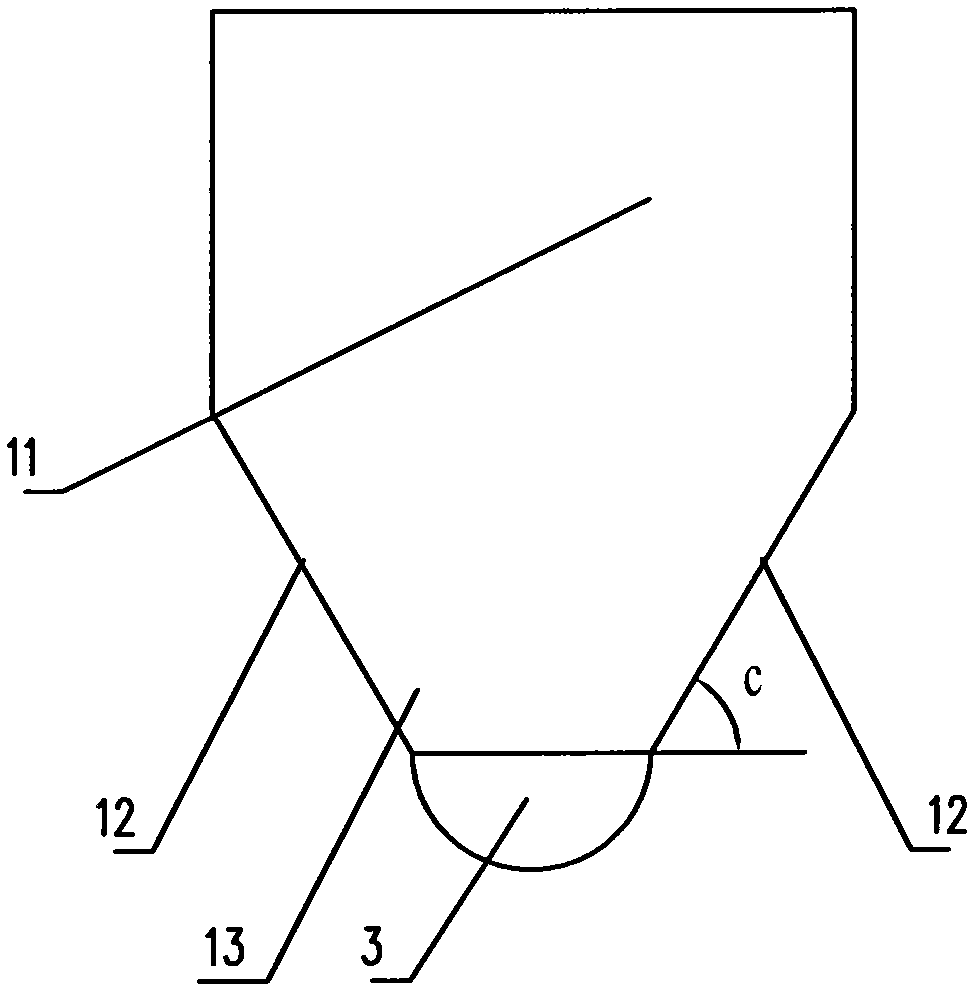

[0051] In the settling water tank 1, a screw conveyor 3 is arranged at the bottom of the settling water tank 1. The height of the screw conveyor 3 gradually increases along the conveying direction of the mud, and the angle...

Embodiment 2

[0059] Such as figure 2 Shown is the sedimentation type solid-liquid separation device described in this embodiment. Compared with Embodiment 1, the width of the liquid inlet tank of the solid-liquid separation device in this embodiment is 0.6 of the width of the settlement tank 1 times, as an optional embodiment, the width of the liquid inlet tank of the present invention can also be set to any size that allows the adsorption liquid 2 to enter the settling water tank 1;

[0060] In the present embodiment, the height of the screw conveyor 3 gradually increases along the conveying direction of the mud, the angle b between the screw conveyor 3 and the horizontal plane is 20°, and the screw shaft diameter of the screw conveyor 3 is 100mm. The diameter of the helical blade on the described helical shaft is 5 times of the diameter of the helical shaft, and the pitch of the helical blade is equal to the diameter of the helical blade. The included angle b can also be set to other a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com