Thin-wall metal support leg and production method thereof

A technology of metal support and production method, which is applied to the legs of general furniture, tables, furniture parts, etc., can solve the problems of high production efficiency, low production efficiency, and low development cost, and achieve low production cost, high production efficiency, and good shape powerful effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific implementation of the thin-walled metal support foot and its production method according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

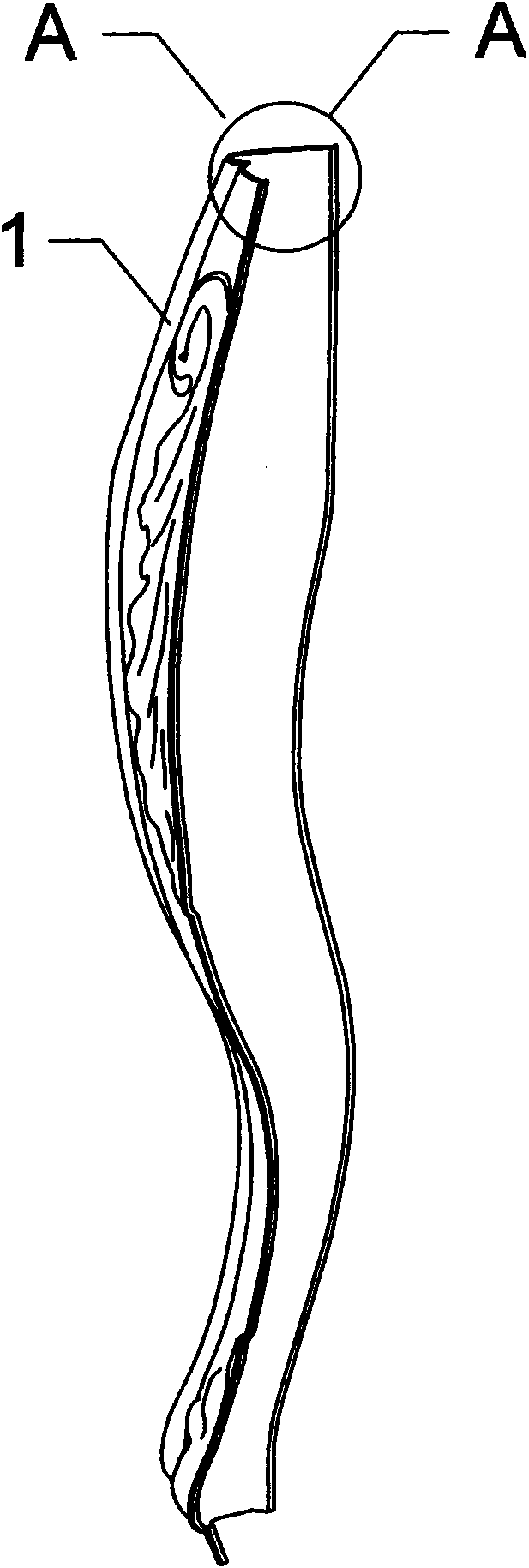

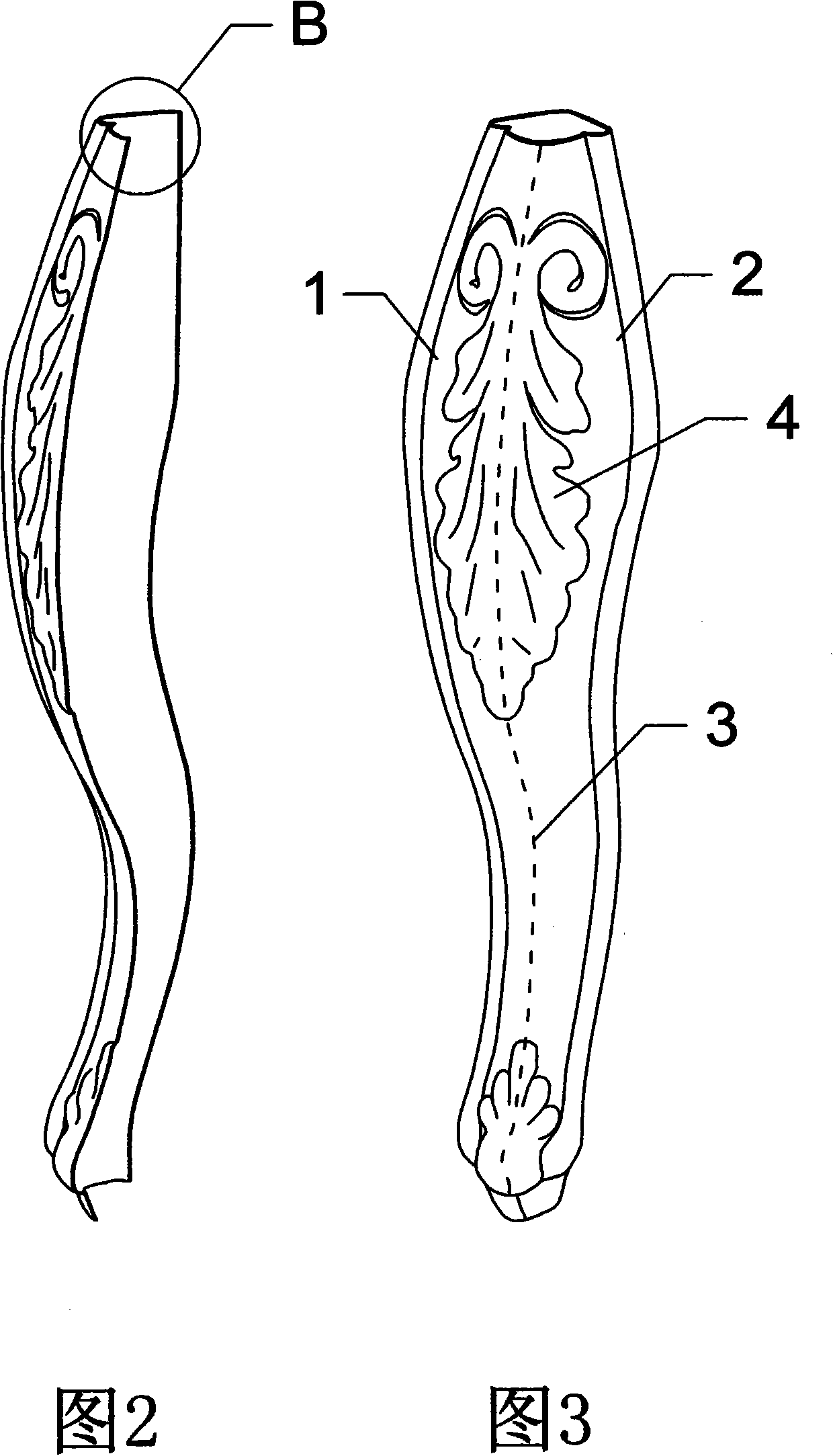

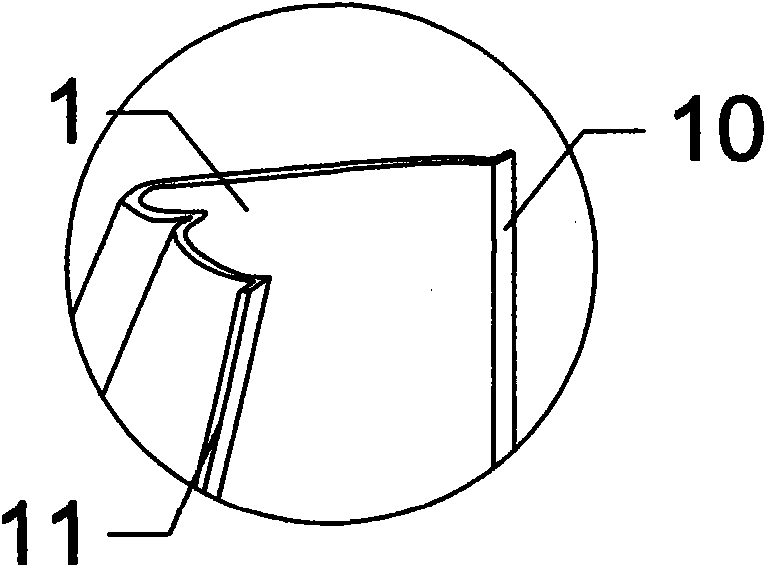

[0019] Such as Figure 1-5 As shown: the thin-walled metal support foot according to the present invention includes two punched and formed support parts 1 and 2. The support part 1 and the support part 2 are arranged opposite to each other and welded as a whole. The joints of the two support parts coincide.

[0020] The production method for manufacturing thin-walled metal support feet includes the following steps: a. According to the shape requirements of the support feet, select the material, thickness and size of the metal sheet, and process the metal sheet with suitable material and size by stamping technology once or more times , to form a support with an opening. The stamping technology processing process includes one or more of the processes of cutt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com