A disperser arrangement for a spray dryer absorber

A spray dryer and disperser technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as complex methods and poor gas purification, and achieve the effects of risk reduction, efficient removal, and efficient drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

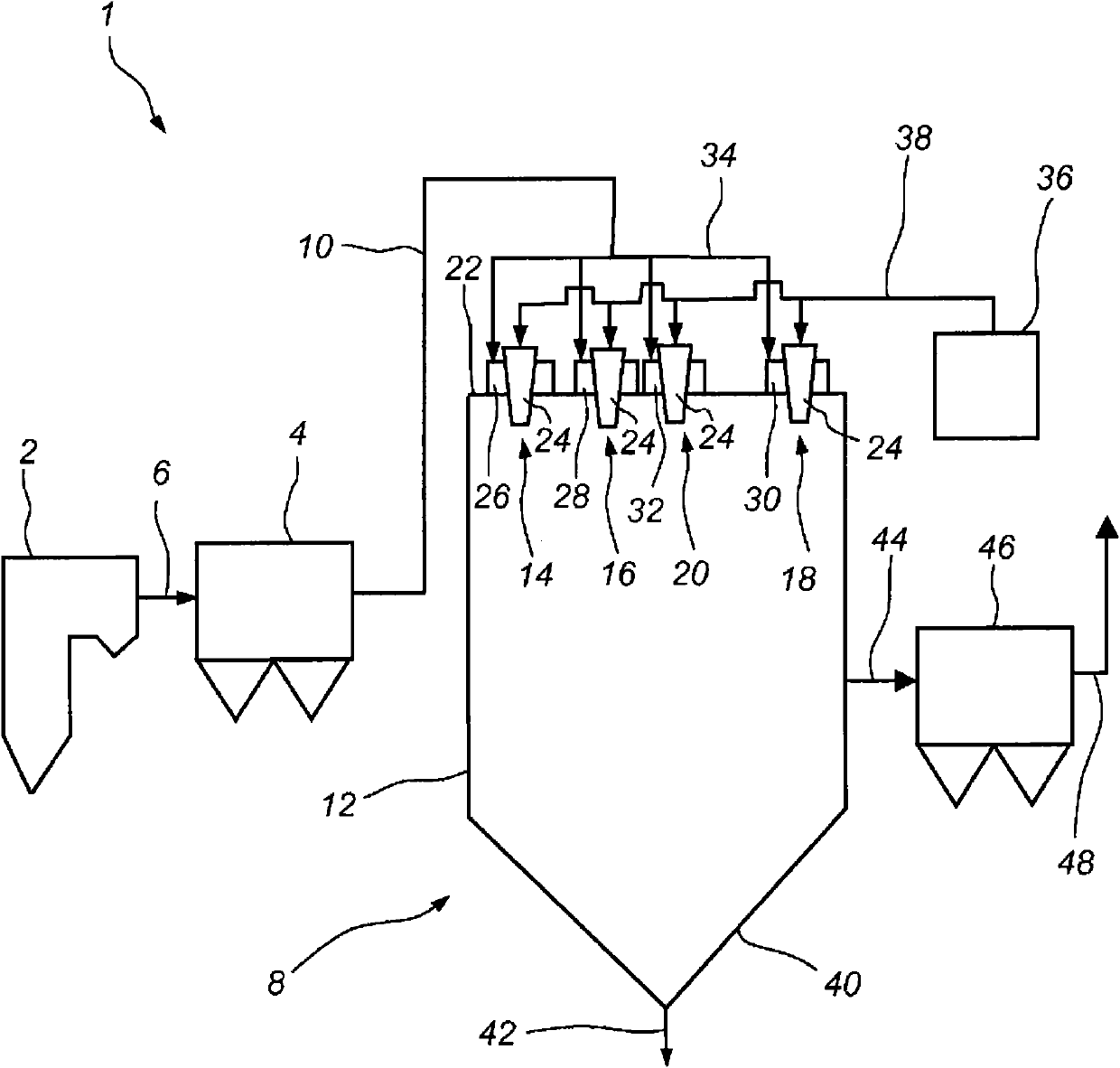

[0026] figure 1 is a schematic side view and shows the power plant 1 . The power plant 1 includes a boiler 2 in which a fuel such as coal or oil is burned. Combustion of the fuel produces hot process gases in the form of flue gases. Sulfur species contained in the coal or oil will form sulfur dioxide which will form part of the flue gas. Flue gas proceeds from boiler 2 to electrostatic precipitator 4 via duct 6 . An electrostatic precipitator 4 (an example of which is described in US 4,502,872) is used to remove dust particles from the flue gas.

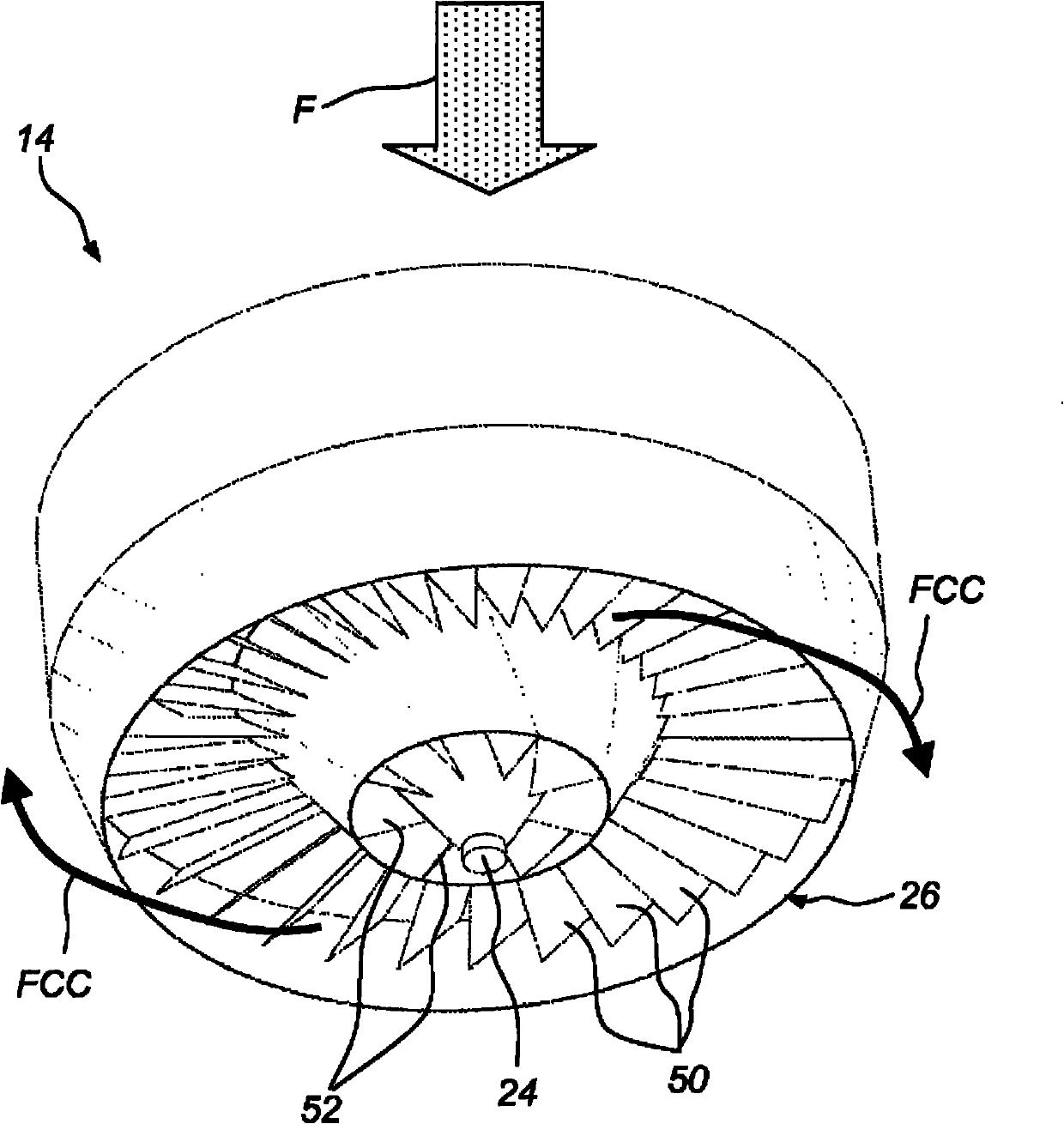

[0027] The flue gas, from which most dust particles have been removed, proceeds through duct 10 to spray dryer absorber 8 . The spray dryer absorber 8 comprises a spray dryer chamber 12 and four dispersers 14 , 16 , 18 , 20 mounted at the top 22 of the spray dryer chamber 12 . Each disperser 14 , 16 , 18 , 20 includes an atomizer 24 . The atomizer 24 may be of the so-called rotary atomizer type, in which a wheel spinning at hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com