Exhaust apparatus for transverse engine

A technology for exhaust devices and exhaust purification devices, which is applied in the direction of exhaust devices, power devices, engine components, etc., and can solve problems such as the temperature will not rise early, the cross-sectional area of the tunnel will increase, and the increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

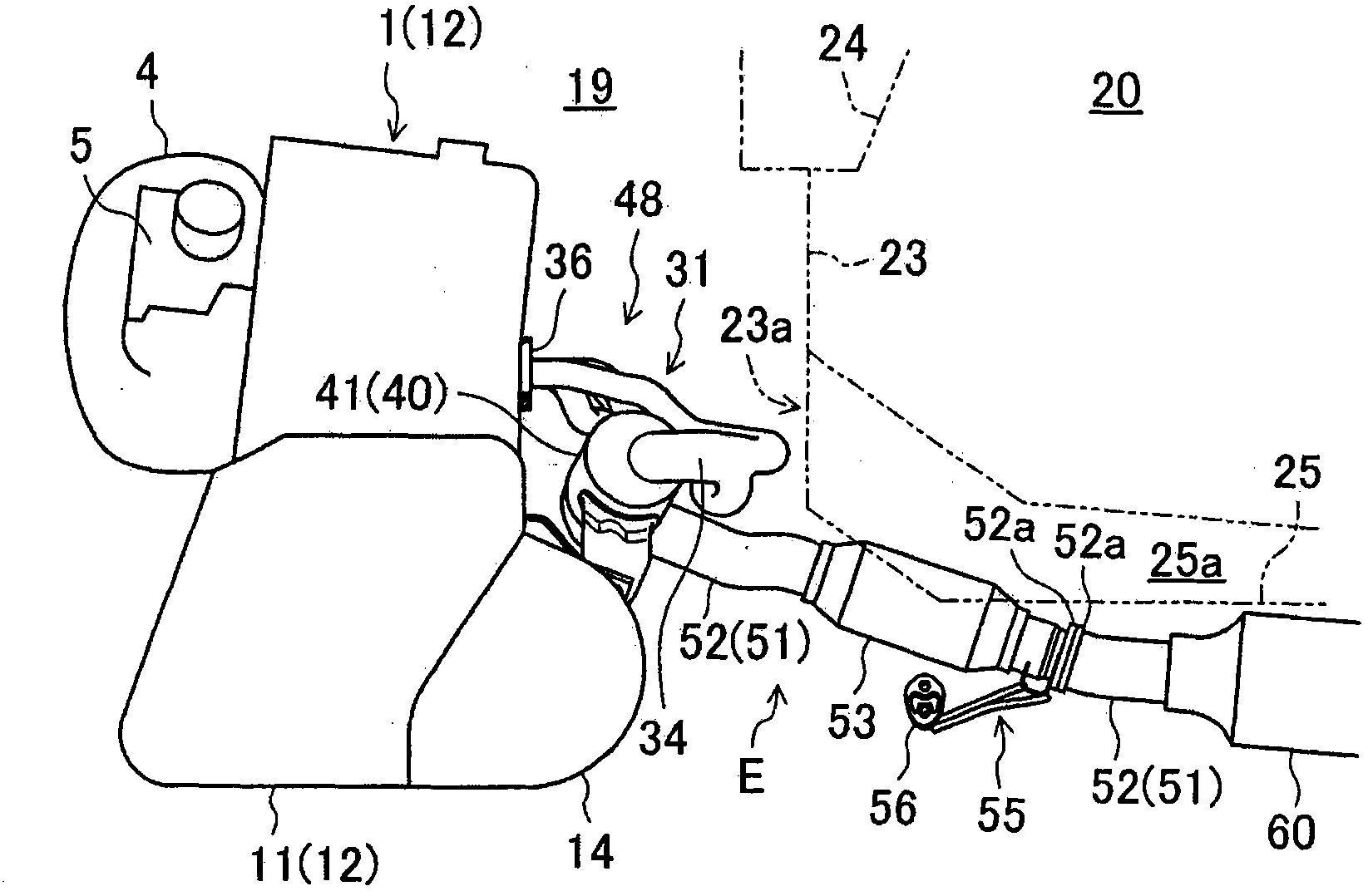

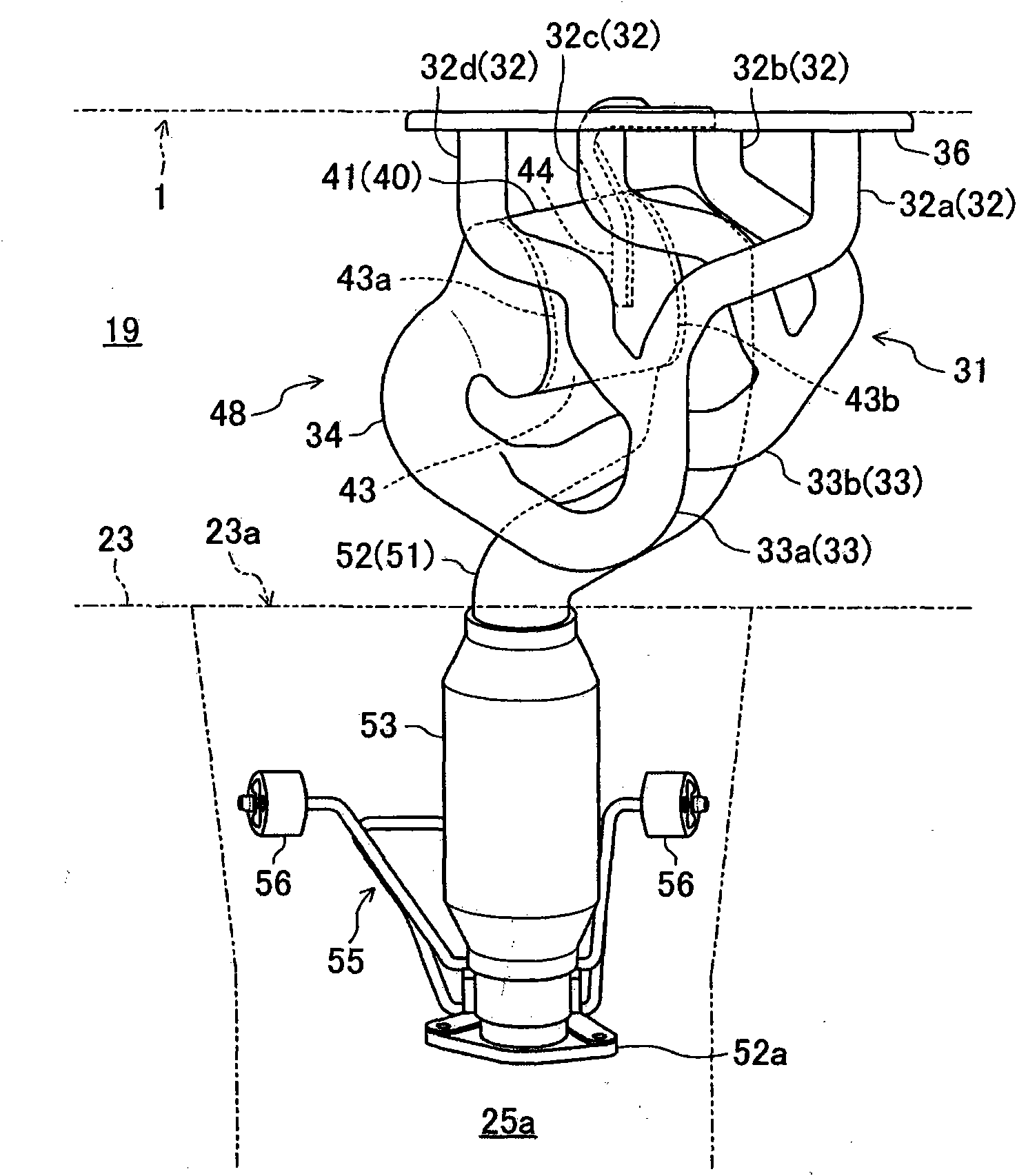

[0025] figure 1 and figure 2 The exhaust device E according to the first embodiment of the present invention is shown, and the exhaust device E is an exhaust device of the engine 1 placed horizontally. The engine 1 is an in-line 4-cylinder engine having four cylinders 2 in a row, and the row direction of the cylinder faces the vehicle width direction ( figure 1 The state of the left-right direction) is laterally arranged in the engine room 19 at the front of the vehicle. Below, will correspond to figure 1 The right side of ( figure 2 The right side of the vehicle is called the right side of the vehicle and will correspond to figure 1 Left of ( figure 2 The left side of the vehicle is called the left side of the vehicle and will correspond to figure 1 The upper side ( figure 2 The front side of the vehicle is called the front side of the vehicle and will correspond to figure 1 The underside ( figure 2 The rear side of the vehicle is called the rear side of the vehicle.

[0026...

Embodiment approach 2

[0058] Figure 6 ~ Figure 8 Shows the second embodiment of the present invention, the ends of the first and second intermediate merging pipe portions 33a, 33b on the exhaust upstream side (the merging portion of the first branch pipe portion 32a and the fourth branch pipe portion 32d, and the second branch The positional relationship between the pipe portion 32b and the junction of the third branch pipe portion 32c) is different from that of the first embodiment described above.

[0059] That is, in the present embodiment, the end portions on the exhaust upstream side of the first and second intermediate junction pipe portions 33a, 33b are both arranged in the vehicle width direction at substantially the same position as the third junction portion 37c, and are arranged in the vertical direction. Misplaced configuration. Specifically, the method of joining the first branch pipe portion 32a and the fourth branch pipe portion 32d is the same as that of the above-mentioned first embo...

Embodiment approach 3

[0065] Figure 9~Figure 11 In the third embodiment of the present invention, the ends on the exhaust upstream side of the first and second intermediate merging pipe portions 33a, 33b (the merging portion of the first branch pipe portion 32a and the fourth branch pipe portion 32d, and the second branch The positional relationship between the pipe portion 32b and the junction of the third branch pipe portion 32c) is further different.

[0066] That is, in the present embodiment, the end portions on the exhaust upstream side of the first and second intermediate junction pipe portions 33a, 33b are arranged in the vehicle width direction substantially the same as the third junction portion 37c as in the second embodiment. However, the end portions on the exhaust upstream side of the first and second intermediate junction pipe portions 33a, 33b do not overlap each other in a plan view, and are shifted from each other in the vehicle front and rear direction. Specifically, the length of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com