Roller bearing for underwater applications

A technology for rolling bearings and bearings, which is applied in the direction of rolling contact bearings, rotating bearings, bearings, etc., which can solve the problems of difficult maintenance and replacement of bearings, and achieve weight saving, high rotation accuracy, and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

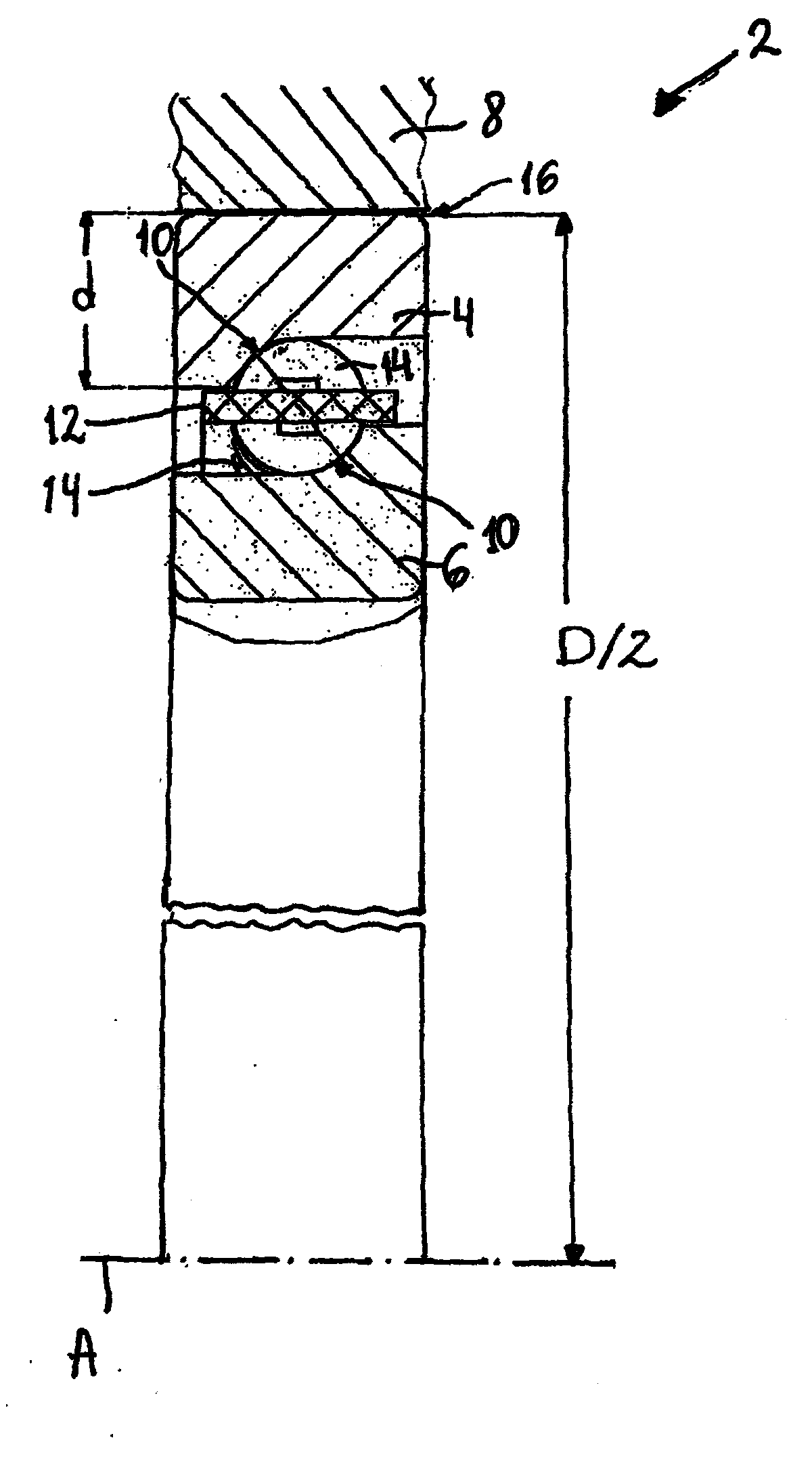

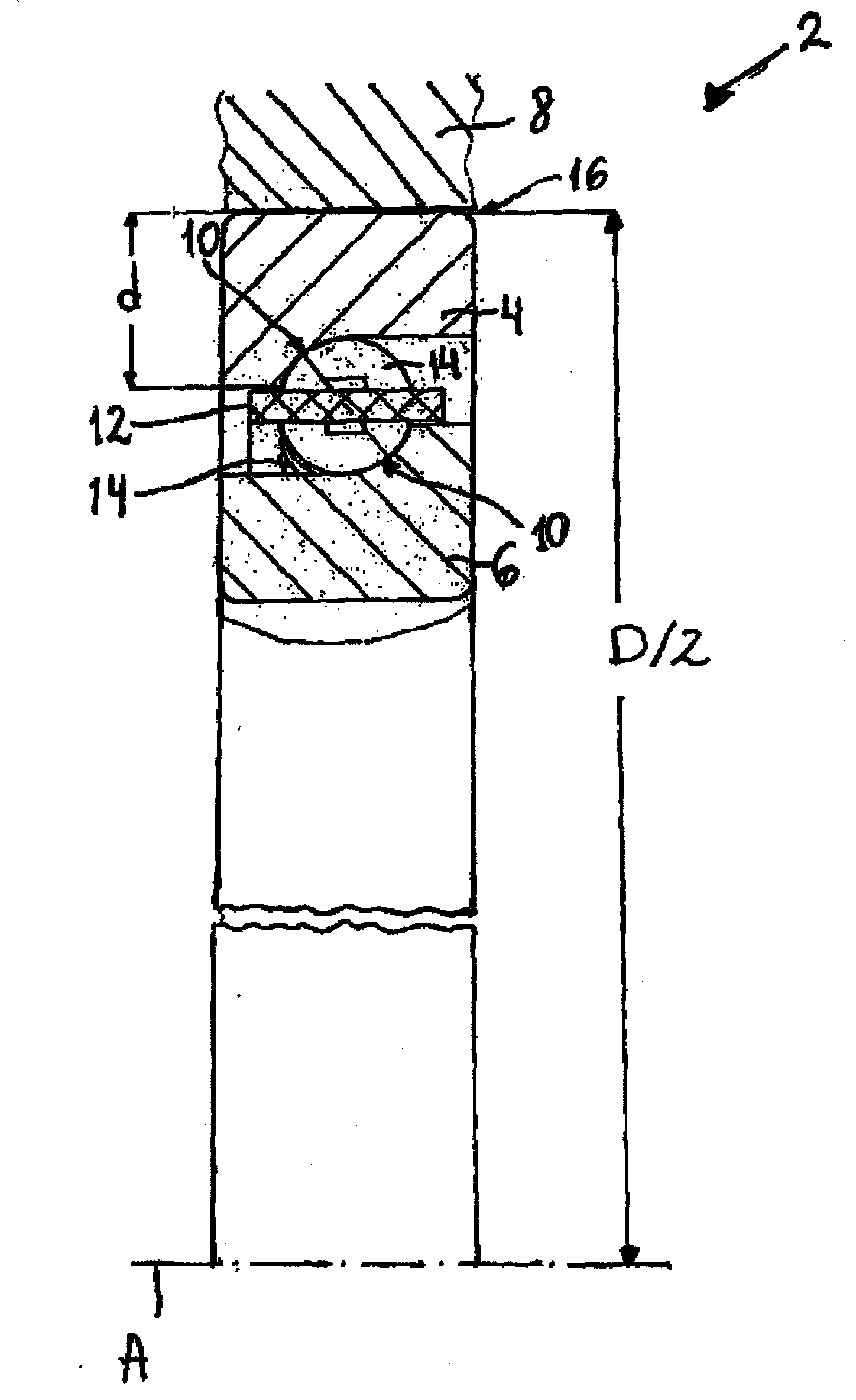

[0017] The drawing shows a rolling bearing 2 which is used, for example, in underwater turbines. The bearing 2 comprises an outer ring 4 and an inner ring 6 which are arranged in a bearing housing 8 from which only a small section can be seen. The bearing rings 4 , 6 have a running surface 10 on which a plurality of rolling bodies 14 held in a cage 12 roll, the rolling bodies being arranged one behind the other in the circumferential direction. The spherical rolling bodies 14 roll around the axis of rotation A of the bearing 2 during bearing operation. Both the bearing rings 4 , 6 and the rolling elements 14 are made of a corrosion-resistant material, for example of stainless iron-chromium-molybdenum steel or of a ceramic material. Cage 12 is made of polyetheretherketone (PEEK) in this exemplary embodiment.

[0018] Due to the field of application of the rolling bearing 2 , the bearing housing is provided with openings (not further shown), so that the water used as cooling m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com