Bubbling and stirring type liquid-replenishing device with texturing tank

A liquid replenishing device and texturing groove technology, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, post-processing details, etc., can solve the problems affecting the stability of the texturing process, achieve ideal effects, ensure the quality of texturing, and improve the quality of the texturing. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

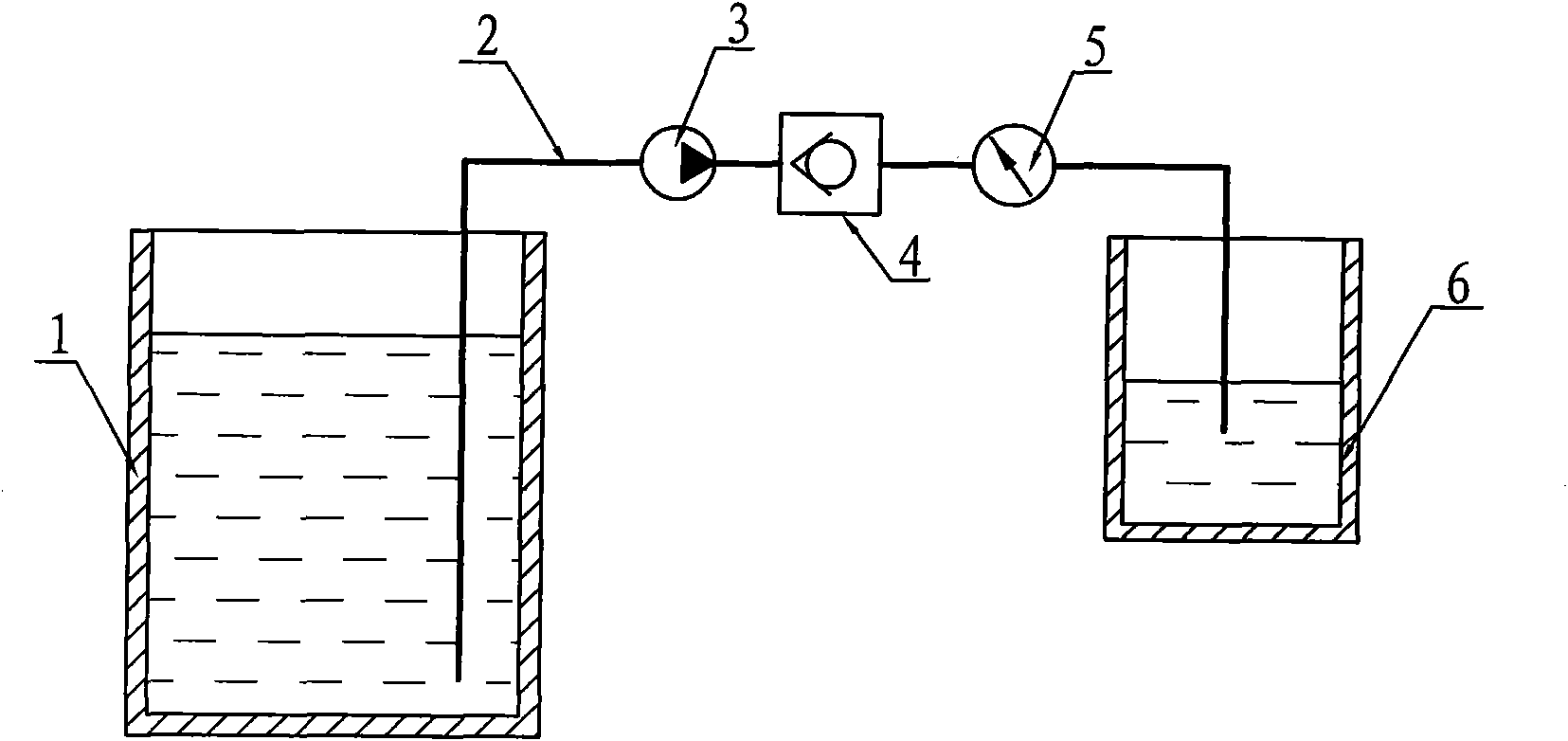

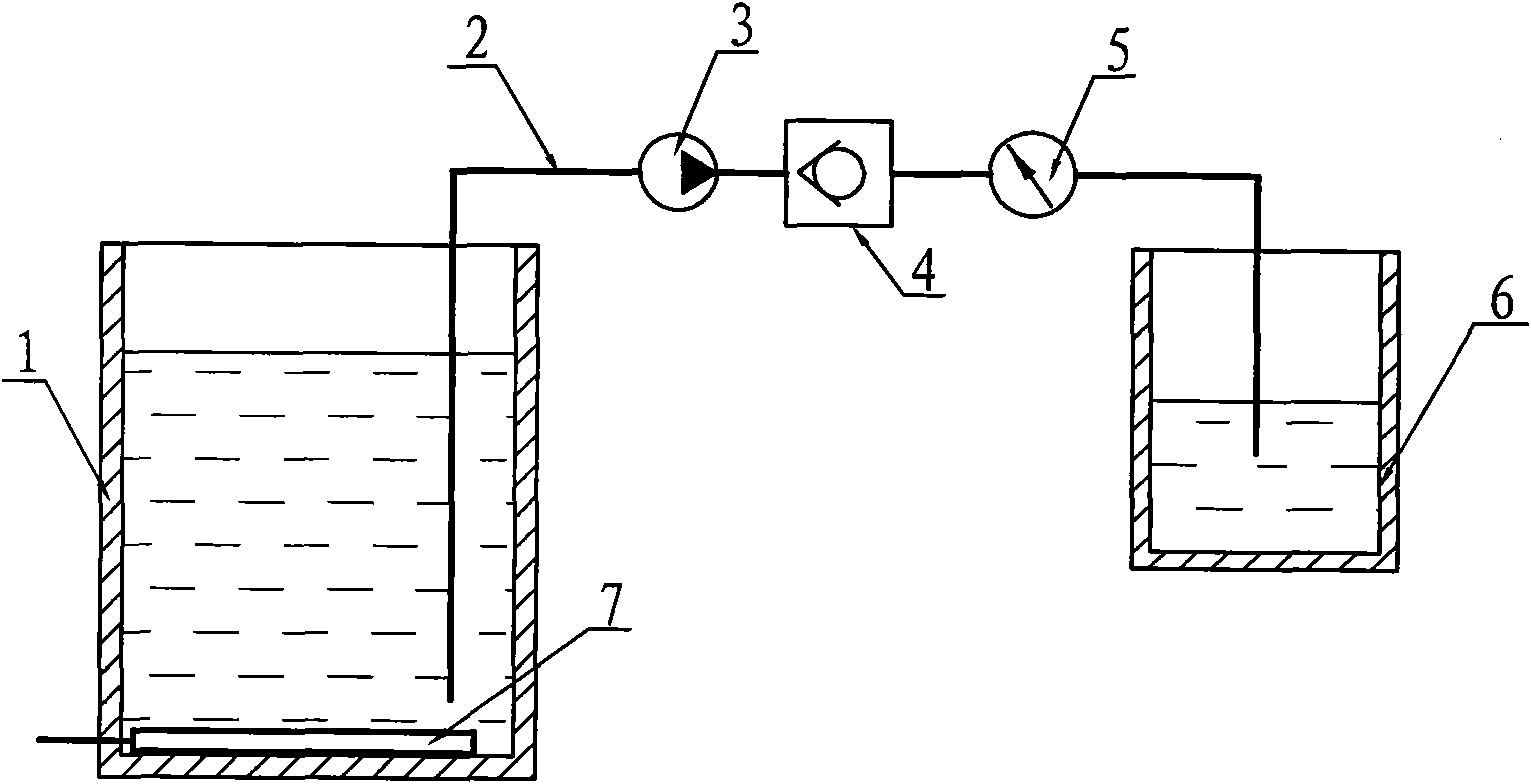

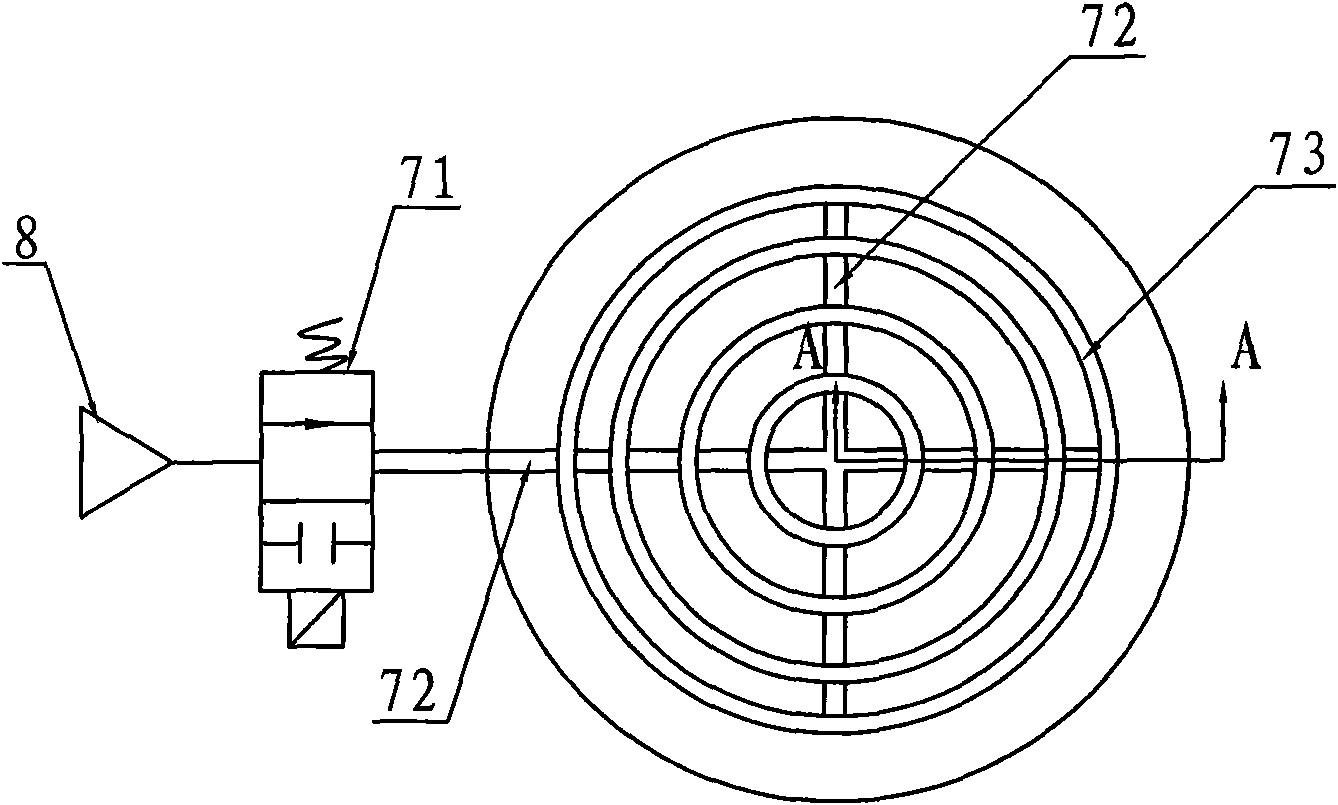

[0018] The bubbling stirring type texturing tank liquid supplement device, such as figure 2 , image 3 , Figure 4 As shown, it includes a liquid storage tank 1, an infusion tube 2, a liquid supplement pump 3, a one-way valve 4, a flow meter 5, and a fleece tank 6. The liquid supplement pump 3, a one-way valve 4 and a flow meter 5 are connected in series by the liquid tube 2 Set between the liquid storage tank 1 and the texturing tank 6, the suction port of the liquid supplement pump 3 is connected to the bottom of the liquid storage tank 1 by the infusion tube 2, and the liquid outlet of the flow meter 5 is passed into the texturing through the infusion tube 2 In the tank 6, a bubbling stirring part 7 is provided at the bottom of the liquid storage tank 1. The bubbling stirring part 7 is composed of an electromagnetic reversing valve 71, a main air inlet pipe 72 and a gas branch pipe 73. The main air inlet pipe 72 and the drum The air branch pipe 73 is connected, and the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com