Capillary component for air conditioner

A capillary tube, air conditioner technology, applied in refrigeration components, fluid circulation arrangements, refrigerators, etc., can solve the problems of burnout, affect the appearance, and high labor costs, and achieve a simple and practical structure that is not easy to burn out, easy to install and disassemble. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The operating principle of the air conditioner of the present invention is the same as that of the prior art, and can refer to the prior art, so it will not be described again. The difference between the present invention and the prior art is that the structure of the capillary assembly is different, and it will be described in detail below:

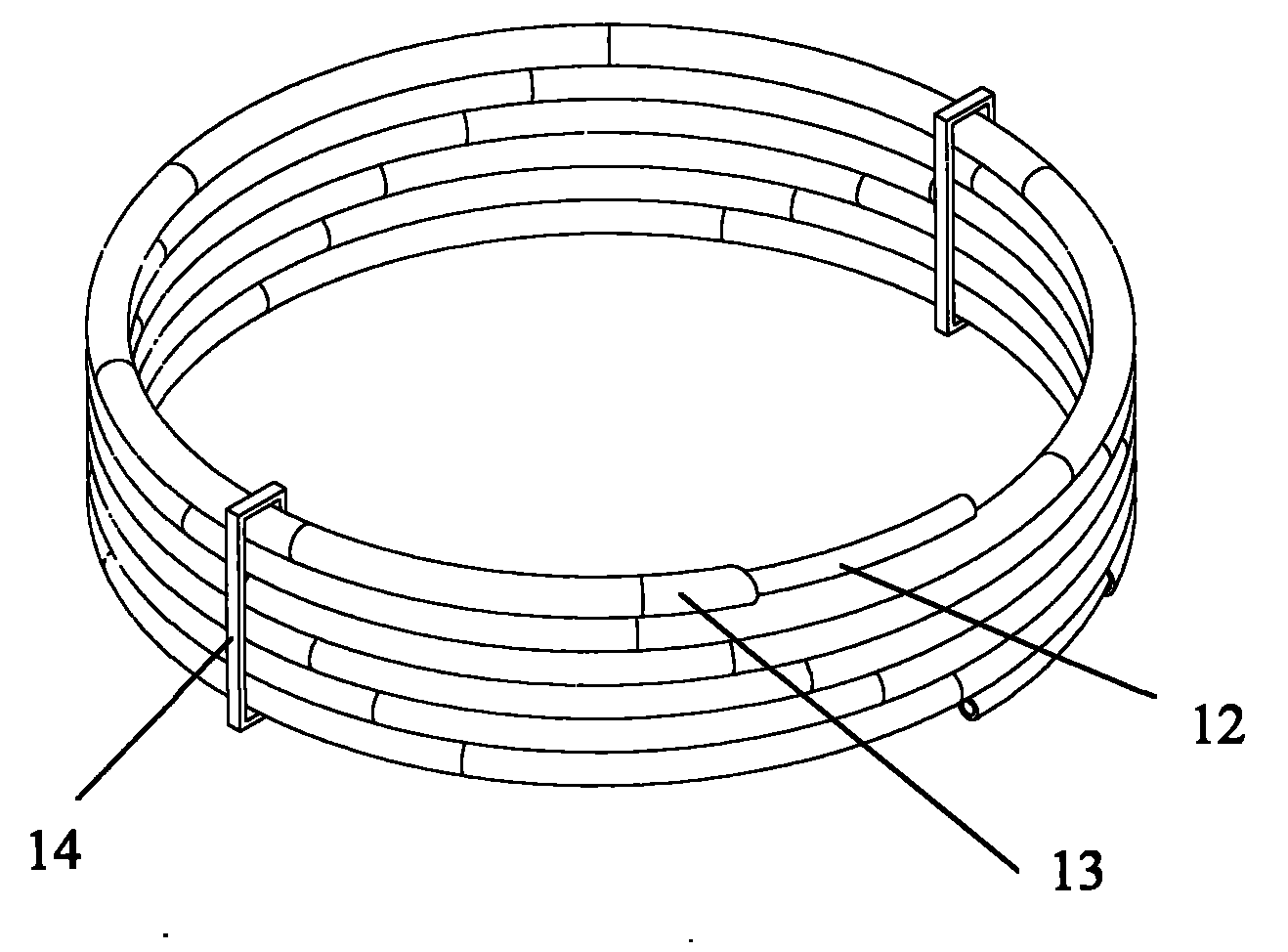

[0019] Such as Figure 4 As shown, in the capillary tube assembly of the air conditioner of the present invention, the multi-turn capillary tubes 22 are directly bound by the fixer 24, and each adjacent turn of the capillary tubes does not contact each other. The fixer 24 is made of plastic material, although it is not shown in the figure, for better fixing, there are two fixers 24, and one (not shown in the figure) is set on the upper part of the capillary 22.

[0020] Specifically, the fixer 24 is composed of a main body 25 and an end cover 26. A partition 27 with the same number of capillary turns is arranged in the middle of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com