Composite spunlace fabric with wood pulp fiber layer

A technology of wood pulp fiber and spunlace cloth, which is applied in the directions of non-woven fabrics, layered products, textiles and paper making, etc. Water absorption and strength improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

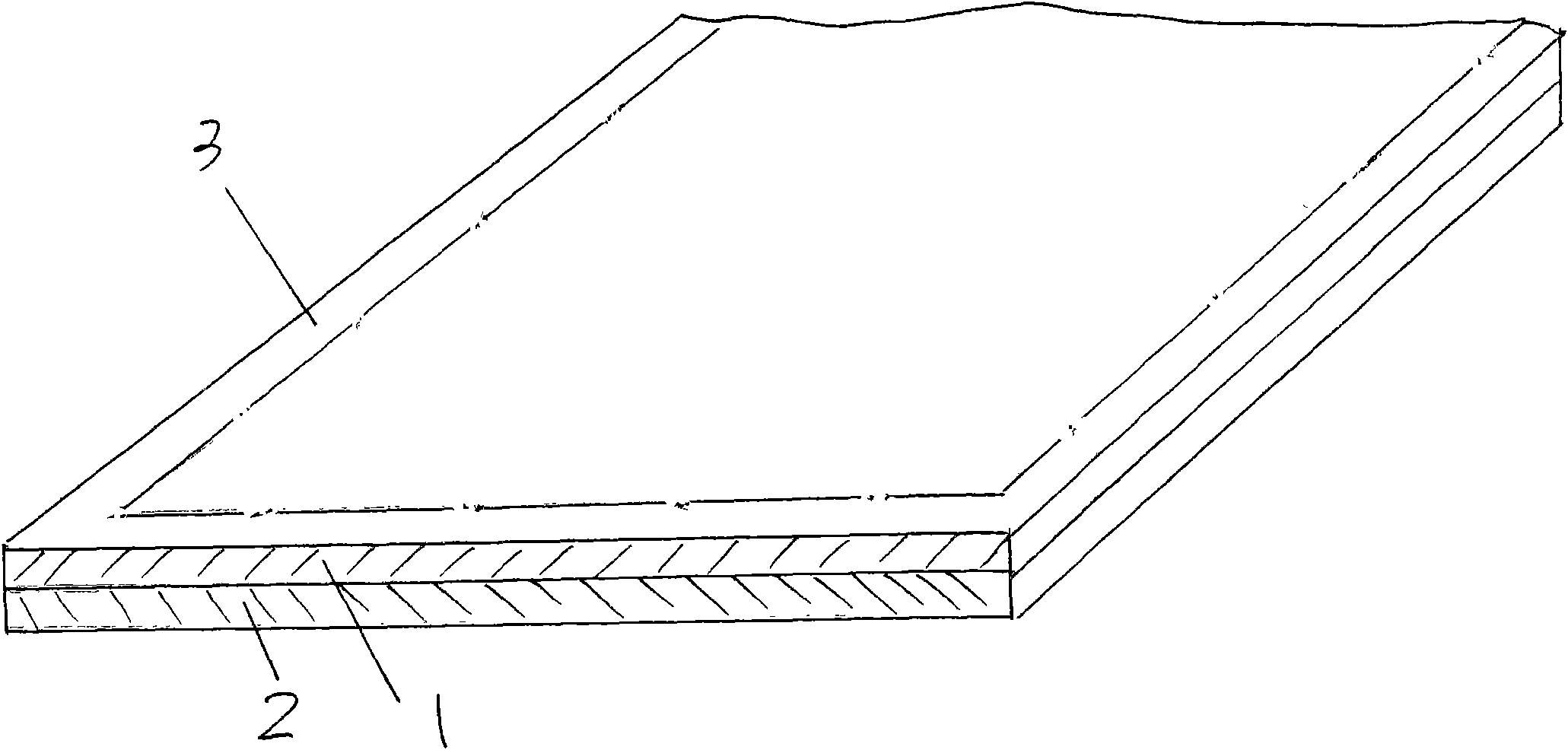

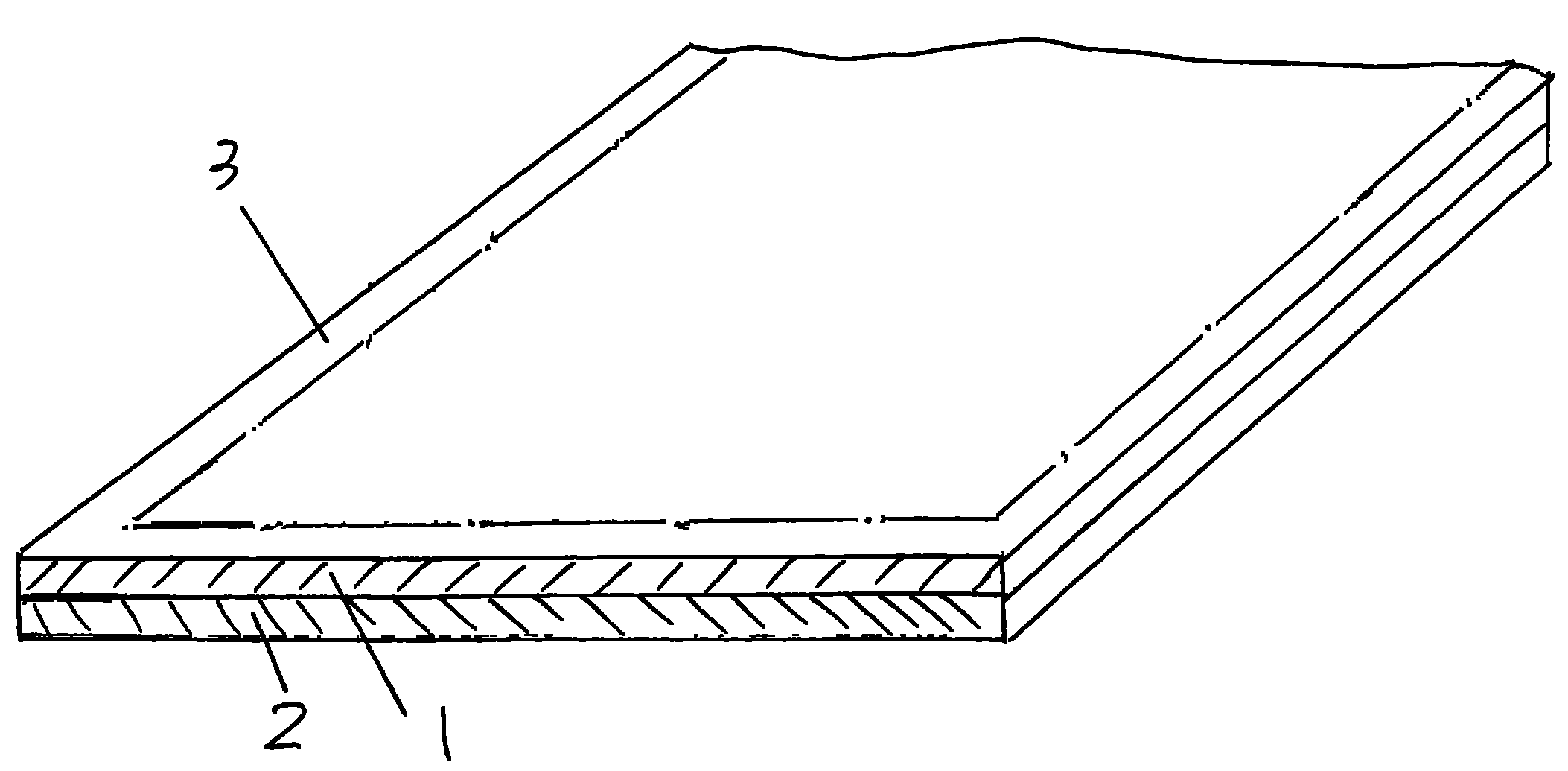

[0014] Please refer to the accompanying drawings, the raw material of the wood pulp fiber layer 1 is wooden pulp board, the pulp board is crushed by a hydraulic pulper and introduced into the pulp storage tank, and then the pulp in the pulp storage tank is introduced into the paper forming machine by the pipeline for forming. And suction dehydration to moisture content 75-85%, then lead out through guide roller, obtain thickness is 40 μ m, the length of fiber is the wood pulp fiber layer 1 of 3mm, textile fiber layer 2 adopts the polyester fiber (chemical fiber) as textile fiber ) The length of the fiber is 40mm, with the customary opener and carding machine used in the production of non-woven products to form a uniform textile fiber layer 2 with a thickness of 40 μm, the thickness of the wet state and the moisture content of 55% is the aforementioned The 40 μm paper surface, that is, the wood pulp fiber layer 1 is superimposed and bonded to one side surface of the textile fibe...

Embodiment 2

[0016] Only change the thickness of the wood pulp fiber layer 1 into 20 μm, and change the fiber length into 8mm; the material of the textile fiber layer 2 is changed to a combination of soybean protein fiber and polyester fiber that is 50% by mass percentage content, and the textile fiber layer 2 The thickness is changed to 25 μm, the fiber length of the textile fiber layer 2 is changed to 50 mm, the moisture content of the paper surface is changed to 80%, and the embossed pattern area 3 is changed to the central part, so that the total thickness is 45 μm. The punctured cloth promptly obtains the composite spunlace cloth that one side is the wood pulp fiber layer 1 and the other side is the textile fiber layer 2 shown in the accompanying drawing, and all the other are the same as the description to embodiment 1.

Embodiment 3

[0018] Only the thickness of wood pulp fiber layer 1 is changed into 10 μm, and fiber length is changed into 5mm; The material of textile fiber layer 2 is changed to the combination of bamboo fiber and milk fiber that each mass percentage content is 50%, the thickness of textile fiber layer 2 Change it to 30 μm, change the fiber length of textile fiber layer 2 to 45mm, change the moisture content of the paper surface to 65%, and the embossed pattern area 3 is located at the edge and middle area of wood pulp fiber layer 1 and textile fiber layer 2, and the rest are all Same as the description of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com