Device and method for coating normal-temperature metal ion flash smelting surface

A metal ion, room temperature technology, applied in melting spraying, metal material coating process, coating and other directions, can solve problems such as high energy cost and loss, and achieve compact structure, outstanding energy saving effect, and high equipment energy utilization rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

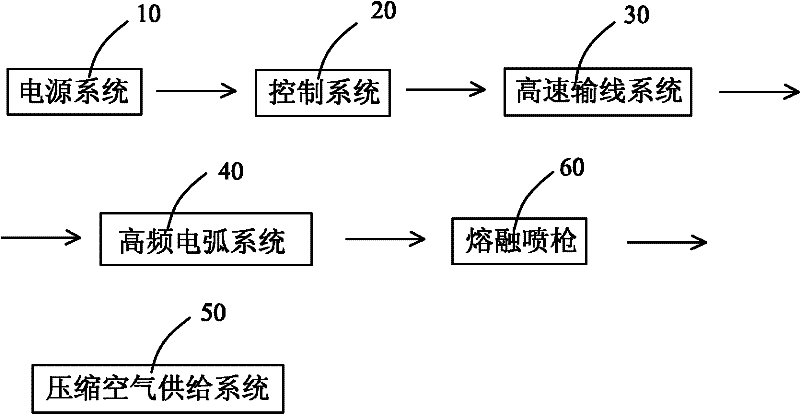

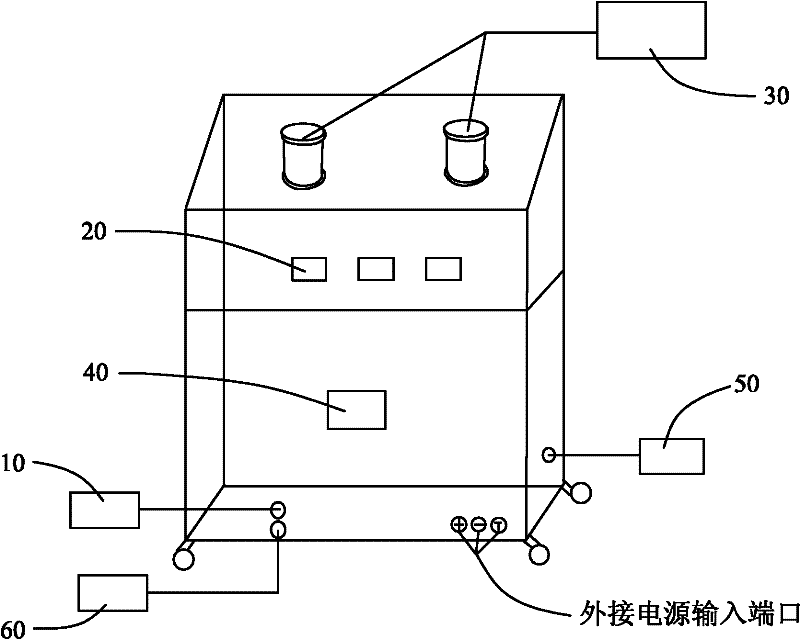

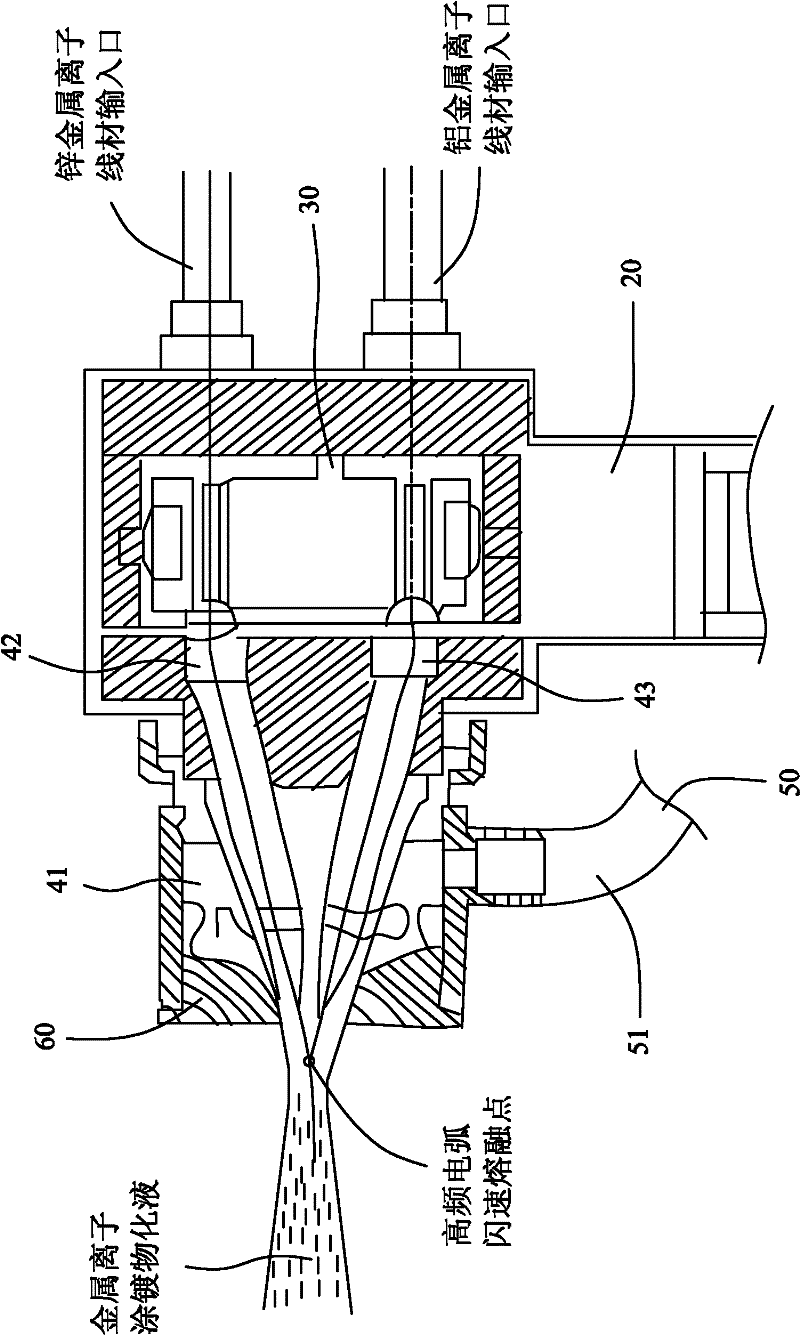

[0025] see Figure 1-3 As shown, the normal temperature metal ion flash melting surface coating device of the present invention mainly includes: a power supply system 10, a control system 20, a high-speed transmission line system 30, a high-frequency arc system 40, a compressed air supply system 50, and a melting spray gun 60 composition. The power supply system 10 is a power supply that uses modern power electronics technology to control the time ratio of switching on and off to maintain a stable output voltage, and is generally composed of a pulse width modulation (PWM) control IC and MOSFET. Such as figure 2 As shown, the power supply system 10 is located at the lower right side of the front panel of the main engine, and mainly supplies the power energy required by the new room temperature metal ion flash melting surface coating device through the control system 20 to each power consumption system.

[0026] The control system 20 is the microcomputer control part of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com