In-mold shearing cylinder of aluminum extruder

A technology of aluminum extrusion and cylinder, which is applied in the direction of fluid pressure actuation device, etc., can solve the problems of difficult replacement of seals and lower work efficiency, and achieve the effect of reducing failure links and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

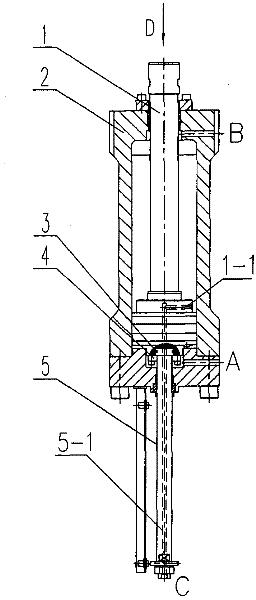

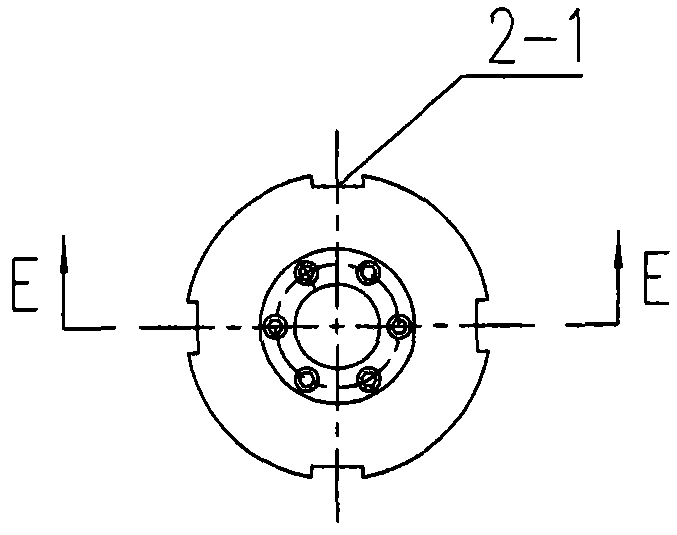

[0017] Such as figure 1 , 2 , 3, an in-mold shearing cylinder of an aluminum extrusion machine, comprising: a cylinder body 2, a piston rod 1, a detection rod 5 located at the bottom of the cylinder body 2 connected to the piston rod 1, and a matching hydraulic system , the piston rod 1 and the detection rod 5 are connected by screws through the pressure plate 4, the detection rod 5 is provided with a No. 1 channel 5-1 for hot oil circulation, and the piston rod 1 is provided with the No. 1 channel 5-1 communicates with No. 2 channel 1-1 for hot oil circulation. The hydraulic system consists of a main pump system and a circulating cooling system. The main pump system consists of a first reversing valve 6, a one-way Throttle valve 7 forms a loop with ports A and B of the cylinder body 2, and the circulating cooling system consists of a second reversing valve 8, a hose 9, a one-way valve 10, and port C of the detection rod 5. The No. 1 channel 5-1, the No. 2 channel 1-1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com