Synthesis method and application of nano-titanium dioxide for adsorption of heavy metals

A nano-titanium dioxide, heavy metal adsorption technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of small adsorption capacity, difficult heavy metal regeneration, short service life, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

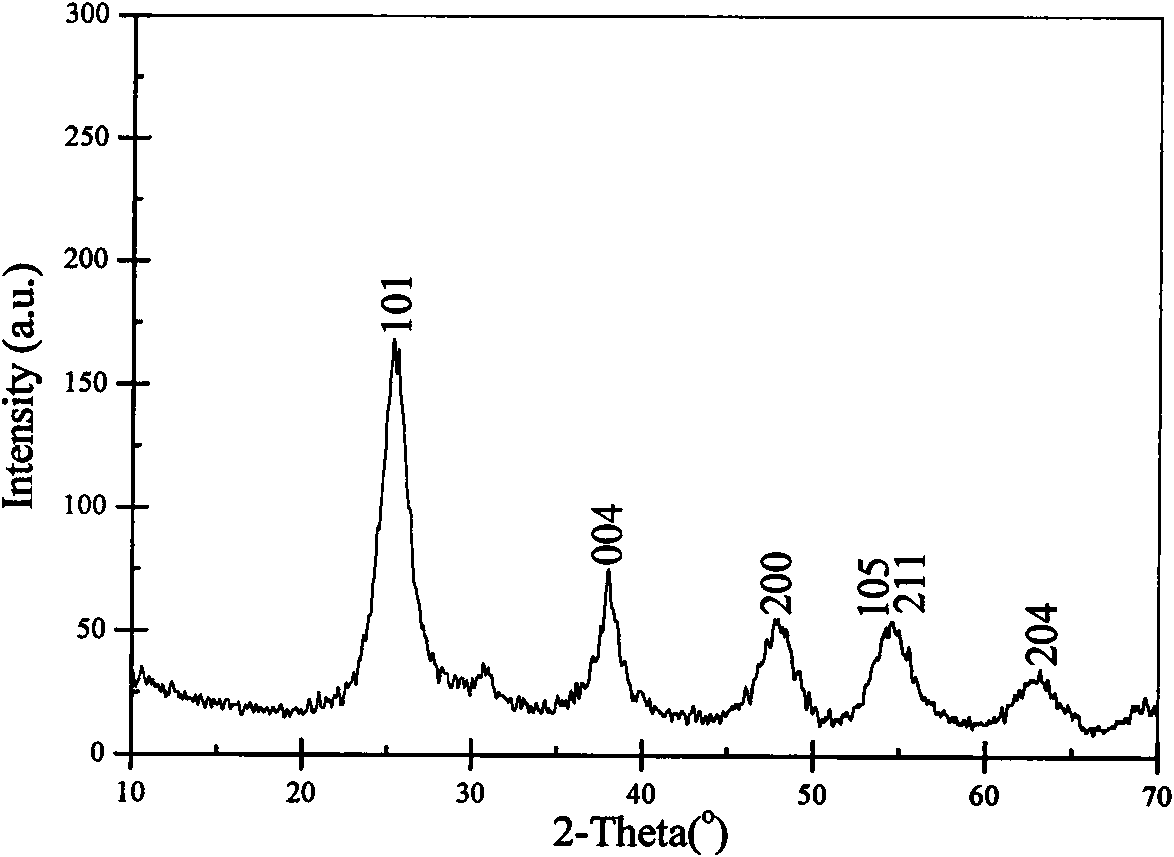

Image

Examples

preparation example Construction

[0029] 1. the preparation method of heavy metal adsorbent of the present invention is as follows:

[0030] (1) The reaction vessel is placed in an ice-water bath;

[0031] (2) Add water to the reaction vessel, and control its temperature between 6~10°C;

[0032] (3) Add titanyl sulfate under stirring, and dissolve evenly;

[0033] (4) Add sodium hydroxide solution drop by drop under high-speed stirring, adjust the pH value of the solution to 5.5-6.5, the optimal value is 6.0, continue the reaction for several minutes, wash the obtained precipitate with water, and filter it several times until the conductivity is 100μs Below, to remove sulfate;

[0034] (5) After the filter cake is dried at a temperature lower than 60° C., it is crushed, sieved and packaged to obtain the product nano-titanium dioxide adsorbent.

Embodiment 1

[0036] Place the reaction vessel with a volume of 10L in an ice water environment, add 1600mL of deionized water, keep the water temperature at 6-10°C, take 300g of titanyl sulfate and slowly add it into the deionized water, stir evenly, and then use a constant flow pump to 10 ml of sodium hydroxide solution with a concentration of 10 M was added dropwise to adjust the pH value to 5.9. The above solution was washed several times with deionized water until the conductivity dropped to 76 μs, and the filtered precipitate was dried at 60° C., pulverized and sieved to obtain 110 g of the product.

Embodiment 2

[0038] Place the reaction vessel with a volume of 2L in an ice water environment, add 250mL of deionized water, keep the water temperature at 6-8°C, take 50g of titanyl sulfate and slowly add it into the deionized water, after stirring evenly, use a constant flow pump to Add 5M sodium hydroxide solution at a rate of 10 ml. When the pH reaches 3.0-3.5, increase the stirring speed, and reduce the dripping speed of the sodium hydroxide solution to control the pH value, and adjust the final pH value to 6.0. The above solution was washed with water several times until the conductivity dropped to 64 μs, and the precipitate obtained after filtration was dried at 60° C., pulverized and sieved to obtain 22 g of the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com