Heat treatment unit of gluing developing machine

A developing machine and gluing technology, which is used in photography, electrical components, opto-mechanical equipment, etc., can solve the problems of insufficient temperature monitoring, insensitive temperature control, uneven temperature, etc., saving time, low cost, and temperature monitoring. accurate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The heat plate structure and circuit system of the heat treatment unit of the glue developing machine will be described below mainly in conjunction with the accompanying drawings.

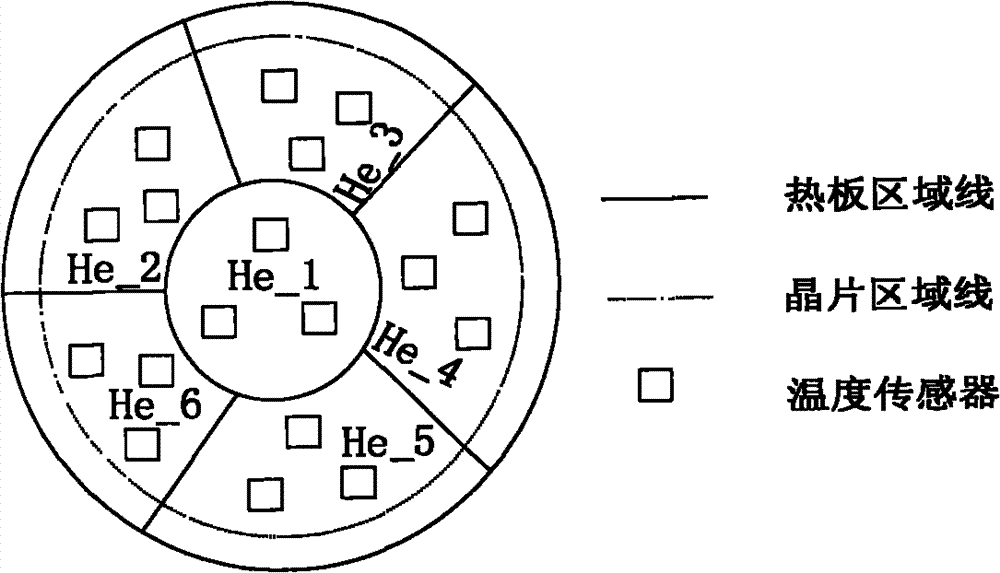

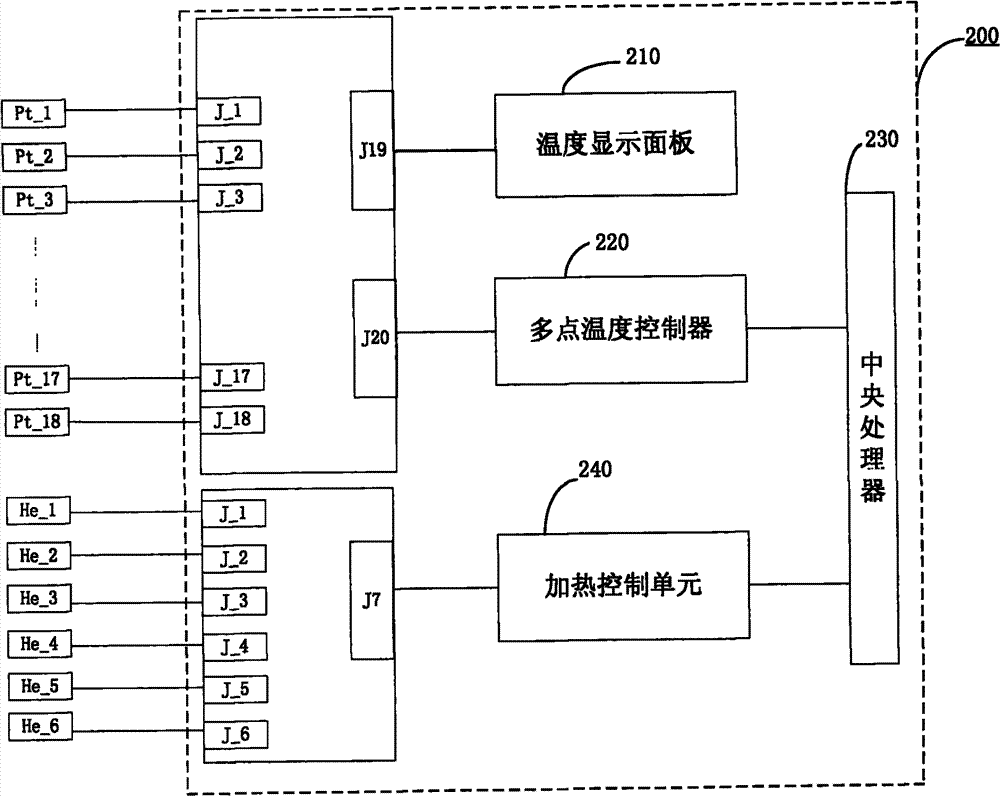

[0017] By dividing one hot plate of the heat treatment unit into multiple hot sub-plates, the wafers are heated separately, and each hot sub-plate has at least one temperature sensor for monitoring, which ensures that once there is a problem with the heat transfer of the hot sub-plate, the temperature will Uneven, the equipment automatically adjusts the temperature or alarms and stops working. Multiple heat sub-plates form a large circular heat plate area, which is monitored separately to ensure the accuracy of temperature processing and the stability of the alarm system, and only need to replace the damaged heat sub-plate instead of the entire heat sink. board, thereby reducing maintenance costs and improving maintenance efficiency.

[0018] The heat treatment unit heat plate can be an adh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com