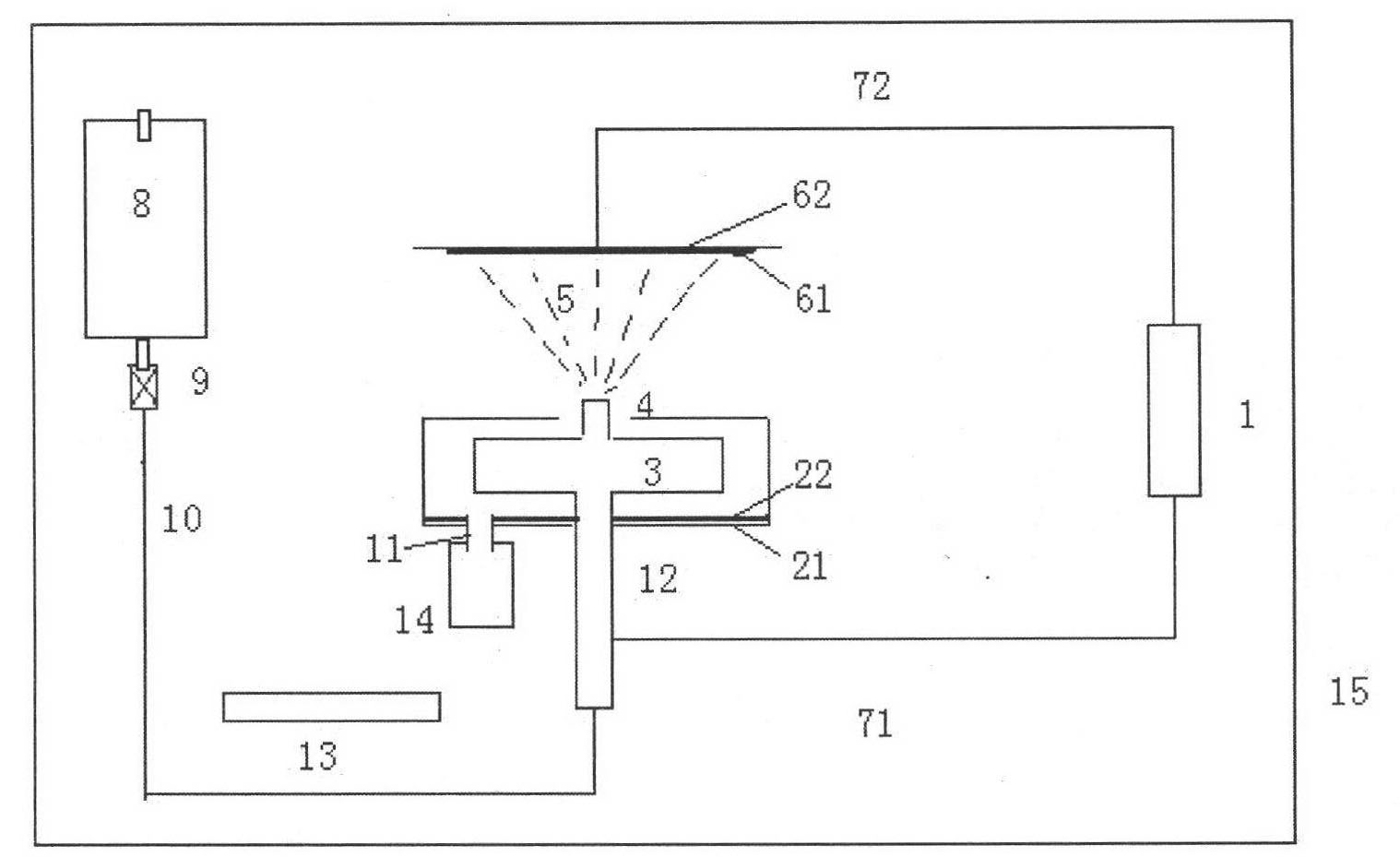

High-voltage electrostatic shuttle nano spinning device

A high-voltage electrostatic and nano-spinning technology, applied in textiles and papermaking, filament/thread forming, fiber processing, etc., can solve problems such as complex equipment structure, high cost and energy consumption, and difficult maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

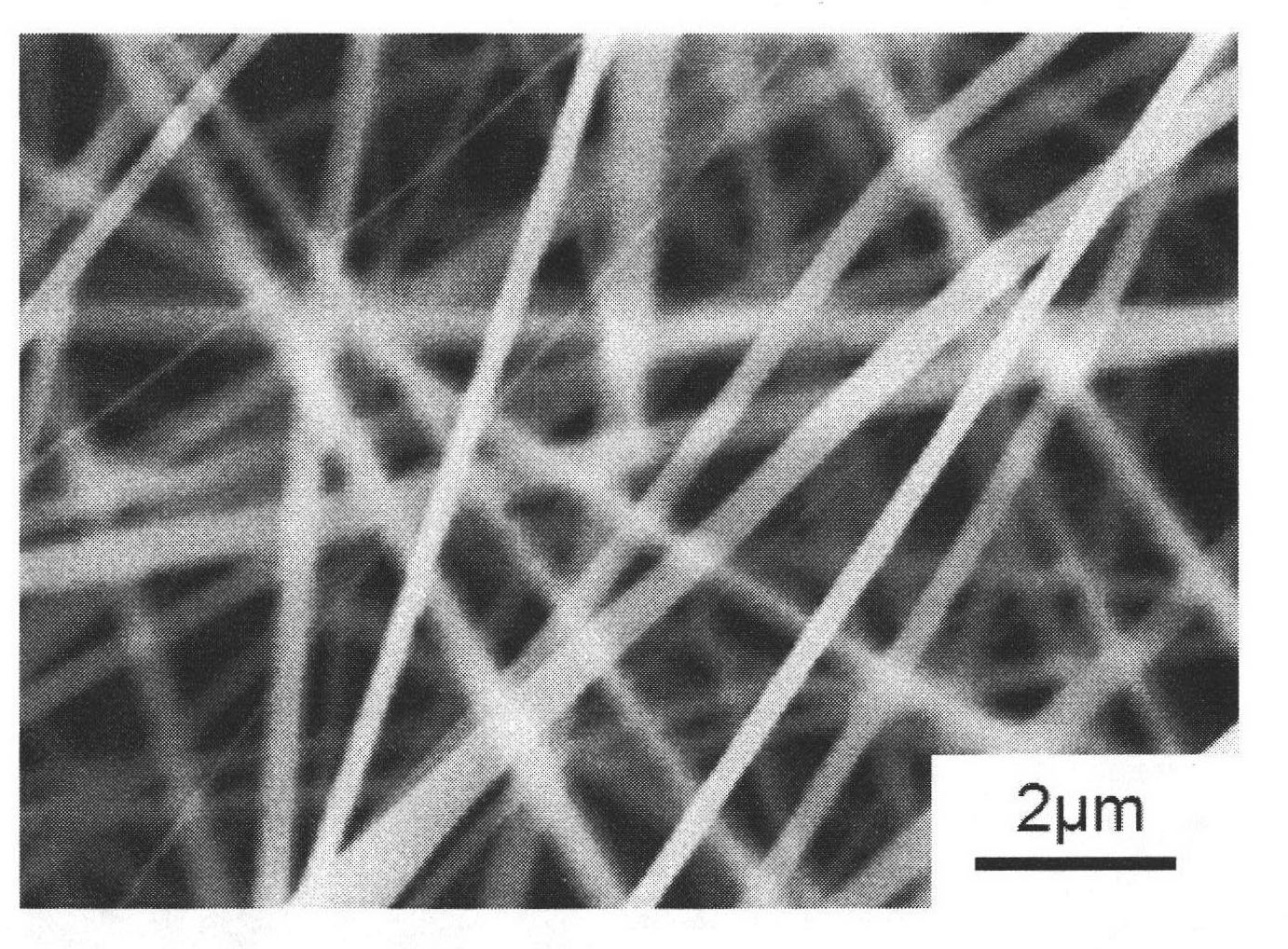

[0029] Add 4g of polyvinylpyrrolidone (PVP, molecular weight: 1,300,000) to 96g of ethanol, and dissolve it with magnetic stirring at room temperature for 2 hours to obtain an electrospinning solution; then add the obtained electrospinning solution to the In the storage tank 8 in the body 15, adjust the electric thermostat 13 to make the temperature and humidity in the casing 15 reach 25° C. and 30% RH respectively, and stabilize for 20 minutes. Open the valve 9 to allow the spinning solution to flow into the liquid storage chamber 3 through the feed pipe 10 and the tubular metal support 12. The electrostatic shed 4 is a slit of 14mm (long) * 0.5mm (wide). The electrostatic shed 4 and The distance between the polypropylene non-woven fabric receiving substrates 61 on the stainless steel receiving plate 62 is 120mm. When the electrospinning solution flows out of the edge of the electrostatic shed 4, the high-voltage electrostatic generator 1 is turned on and slowly adjusted to 3...

Embodiment 2

[0031]Add 4g of polyvinylpyrrolidone (PVP, molecular weight: 1,300,000) to 96g of ethanol, and dissolve it with magnetic stirring at room temperature for 2 hours to obtain an electrospinning solution; add the obtained electrospinning solution to the casing 15 In the storage tank 8 inside. Adjust the temperature and humidity in the box to 25°C and 30%RH respectively, and stabilize for 20 minutes. Open the valve 9 to allow the spinning solution to flow into the liquid storage chamber 3 through the feed pipe 10 and the tubular metal support 12. The size of the electrostatic shed 4 is 14mm (length) × 0.5mm (width). The distance between the shed and the polypropylene non-woven substrate of the receiving plate is 120 mm. When liquid flows out of the edge of the shed, turn on the high-voltage electrostatic generator 1 and slowly adjust it to 40kV. At this time, jets appear and split, and PVP nanofiber non-woven fabrics are formed on the substrate, the spinning efficiency is 0.035g / ...

Embodiment 3

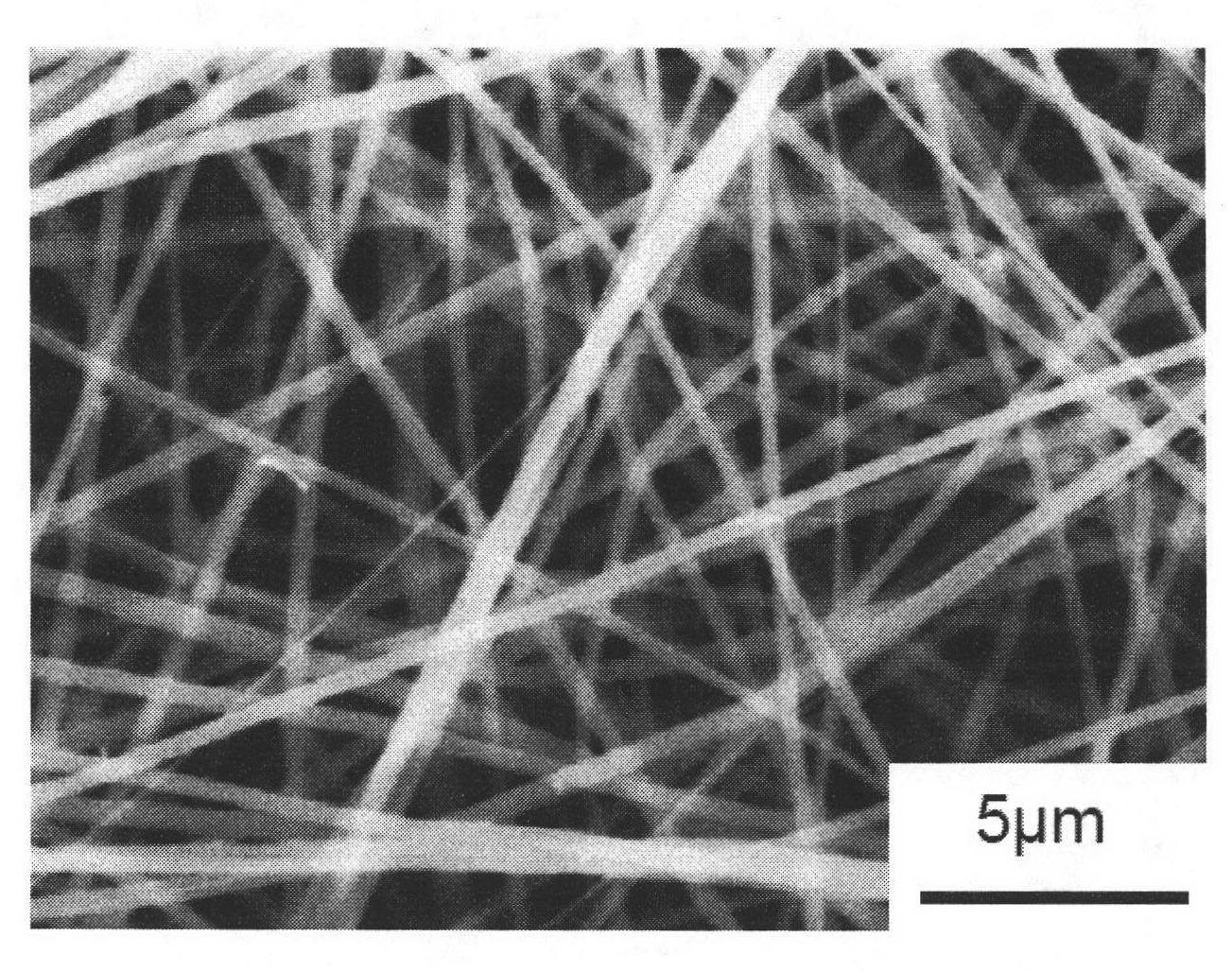

[0033] Add 4g of polyvinylpyrrolidone (PVP, molecular weight: 1,300,000) into 96g of ethanol, and dissolve it for 2 hours at room temperature using magnetic stirring to obtain an electrospinning solution; In tank 8. Adjust the temperature and humidity in the box to 25°C and 30%RH respectively, and stabilize for 20 minutes. Open the valve 9 to allow the spinning solution to flow into the liquid storage chamber 3 through the feed pipe 10 and the tubular metal support 12. The size of the electrostatic shed 4 is 14mm (length) × 0.5mm (width). The distance between the shed and the polypropylene non-woven substrate of the receiving plate is 380mm. When liquid flows out of the edge of the shed, turn on the high-voltage electrostatic generator 1 and slowly adjust it to 70kV. At this time, jets appear and split, and PVP nanofiber non-woven fabrics are formed on the substrate, the spinning efficiency is 0.07g / min, the average diameter is 600nm, and the surface density is 26g / m 2 ,See...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com