Method for extracting high-purity huperzine A and huperzine B from medicinal plant phlegmariurus crutomerianus

A technology for huperzine A and sargassum, applied in the field of extracting high-purity huperzine A and huperzine B, to achieve the effects of short technical route, simplified production process, and increased added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

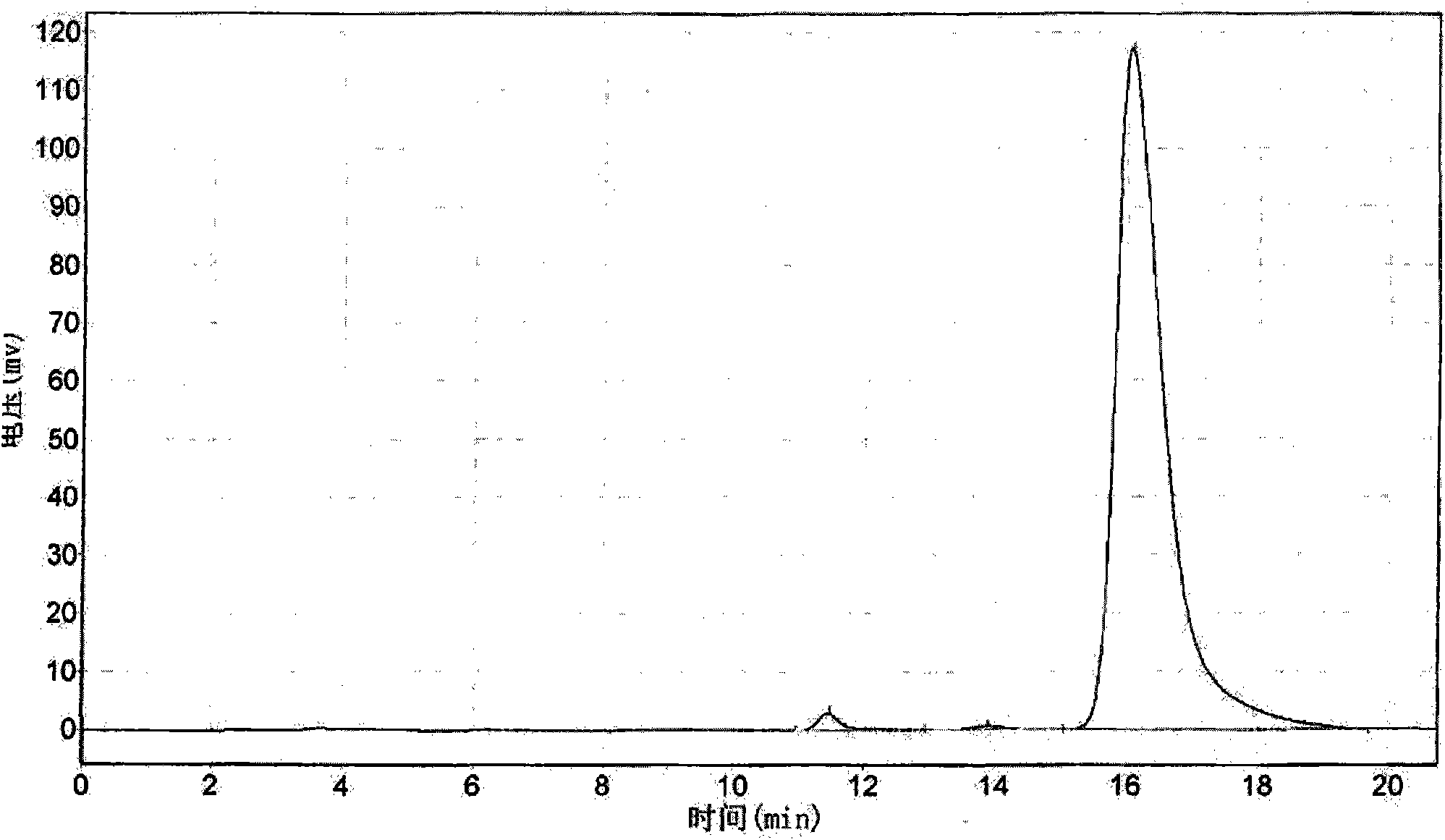

Image

Examples

Embodiment 1

[0029] Grind and dry 50kg of Cedarus fir, add deionized water twice to make saturated acidic water (PH=5) in the amount of 500L and 400L respectively, heat and stir at 80°C for 2h and 1.5h respectively, filter with a microfilter, Put the obtained filtrate on the ion exchange resin, after adsorbing for 30min, elute with 3BV of column liquid ammonia water, concentrate, adjust the pH value to neutral and let stand for 10h, filter to obtain the filtrate, and concentrate to 1 / 15 of the original volume; the filtrate Separation on a reversed-phase chromatographic column, collecting the liquid in sections to obtain liquid 1 (huperzine A) and liquid 2 (huperzine B); respectively extract with a mixed solution of ethyl acetate and petroleum ether (volume ratio = 1:1) Two liquids to obtain Huperzine A crude product and Huperzine B crude product; respectively add 80% ethanol to Huperzine A and Huperzine B crude products according to their volume ratio, add 100-150 times the amount, heat and...

Embodiment 2

[0032]Grind and dry 100kg of Chinese cedar fir, extract twice and add deionized water to form saturated acid water (PH=5), respectively 900L and 700L, heat and stir at 80°C for 2h and 1.5h, respectively, filter with a microfilter, Put the obtained filtrate on the ion exchange resin, after adsorbing for 30min, elute with 3BV of column liquid ammonia water, concentrate, adjust the pH value to neutral and let stand for 10h, filter to obtain the filtrate, and concentrate to 1 / 15 of the original volume; the filtrate Separation on a reversed-phase chromatographic column, collecting the liquid in sections to obtain liquid 1 (huperzine A) and liquid 2 (huperzine B); respectively extract with a mixed solution of ethyl acetate and petroleum ether (volume ratio = 1:1) Two liquids to obtain Huperzine A crude product and Huperzine B crude product; respectively add 80% ethanol to Huperzine A and Huperzine B crude products according to their volume ratio, add 100-150 times the amount, heat an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com