Method for improving sludge anoxic/aerobic digestion property by utilizing ultrasonic pretreatment

A sludge anoxic and ultrasonic technology, applied in the fields of environmental protection and comprehensive utilization of resources, achieves the effects of small footprint and volume, good economic benefits, and mature technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

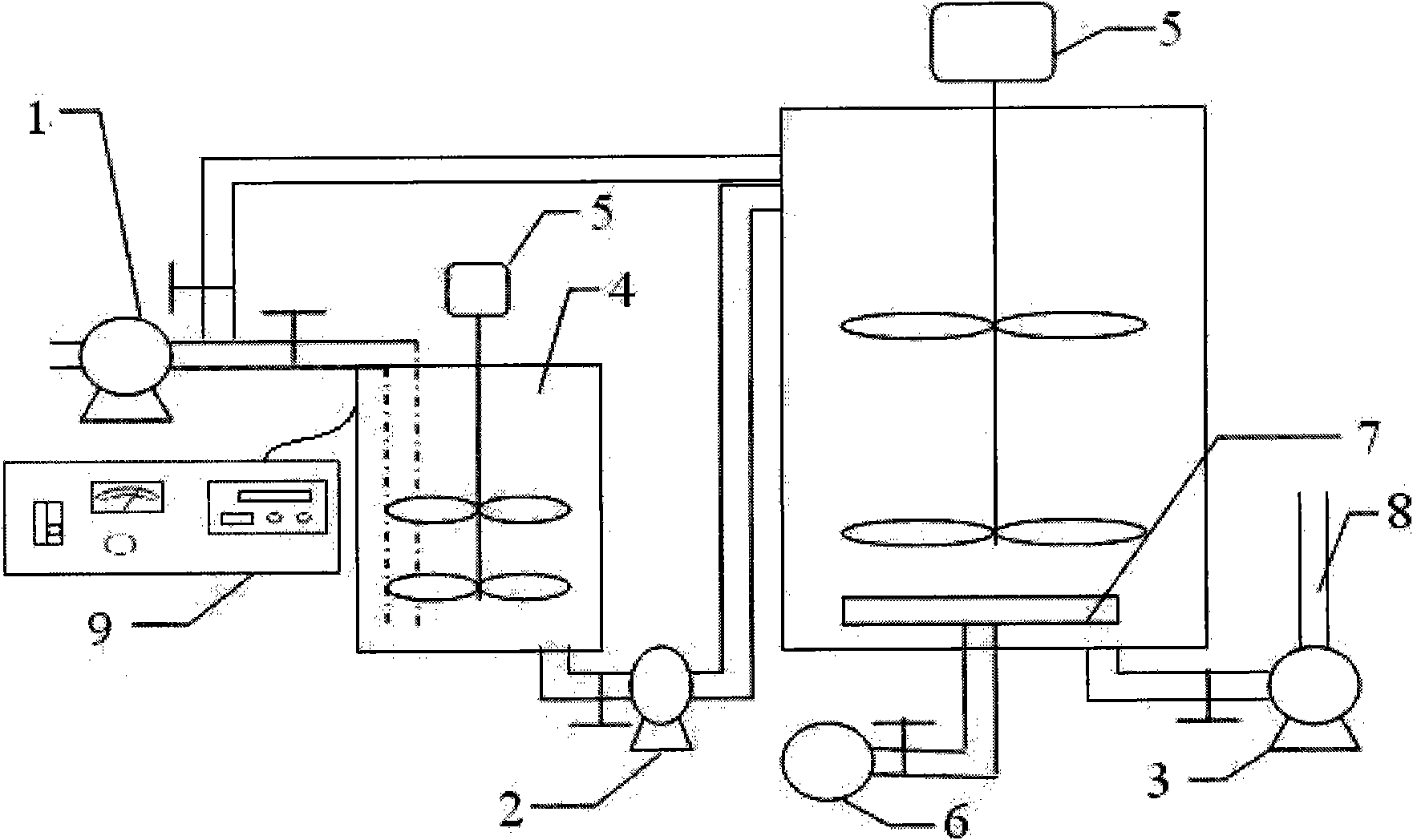

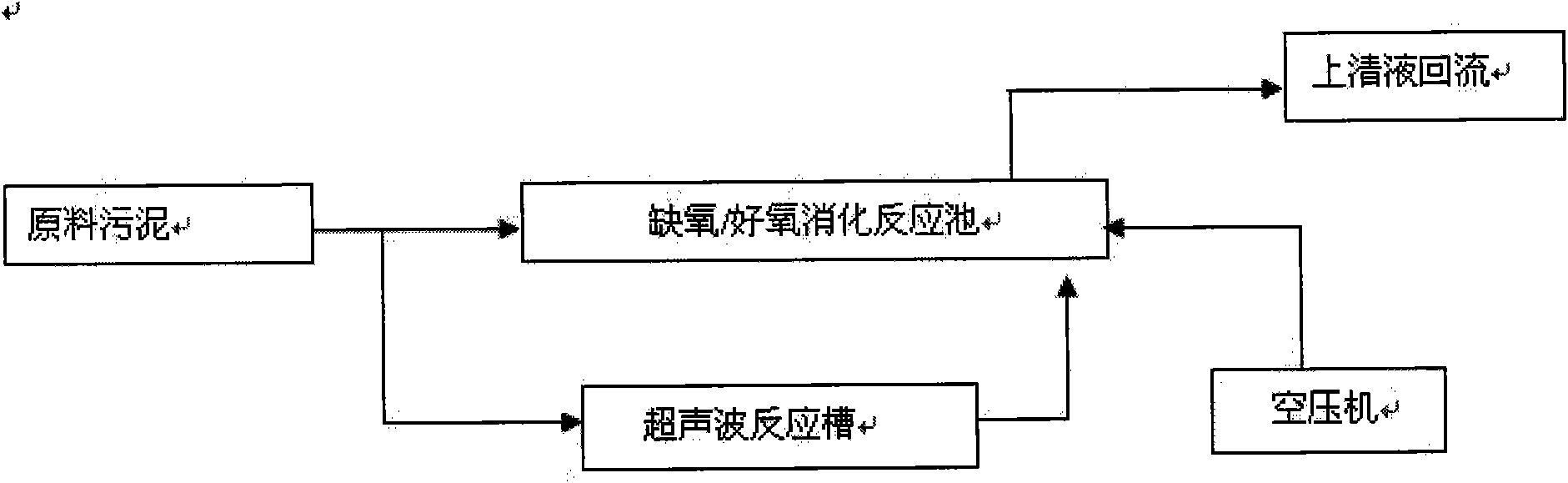

Method used

Image

Examples

Embodiment 1

[0025] Raw sludge (taken from Guangzhou Lijiao Sewage Treatment Plant, sludge moisture content is 98.3%, pH is 6.7, MLSS is 10.5g / L, MLVSS is 5.6g / L, COD in the sludge supernatant is 42mg / L L, ammonia nitrogen is 13mg / L, TP is 4mg / L) is injected into the reaction tank through the sludge inlet pump, the mixer in the reaction tank is turned on (120r / min), anoxic / aerobic alternating environment is provided through intermittent aeration, and the sludge The residence time is 12 days; 24 hours is a cycle, aerobic for 12 hours and anoxic for 12 hours. During the aerobic period, the intake volume is adjusted by the pipeline aeration switch, and the DO is controlled at 5.5-6.0 mg / L. During the reaction, the temperature was controlled at about 25°C. The sludge in the reactor is discharged and fed once every 24 hours. The amount of sludge discharged and fed is 8.3% of the sludge in the sludge anoxic / aerobic digestion bioreactor, and the concentration of the sludge fed is 9.5 ~10.5g / L. ...

Embodiment 2

[0027] The raw sludge (taken from Guangzhou Lijiao Sewage Treatment Plant, the sludge moisture content is 97.3%, the pH is 7.1, the MLSS is 10.2g / L, the MLVSS is 5.4g / L, and the COD in the sludge supernatant is 40mg / L L, ammonia nitrogen is 12mg / L, TP is 10mg / L) respectively injected into the two reaction pools A and B through the mud inlet, the sludge in the A reaction pool is only subjected to anoxic / aerobic digestion, and the sludge in the B reaction pool is subjected to ultrasonic - Hypoxic / aerobic digestion. Other experimental conditions are the same as Example 1. After 11 days of digestion, the MLSS removal rate and MLVSS removal rate of the sludge in the B reaction tank increased by 10.23% and 13.03% respectively compared with the sludge in the A reaction tank and reached stability. The pool digestion time was shortened by 9 days compared with the A reaction pool.

Embodiment 3

[0029] The raw sludge (taken from Guangzhou Lijiao Sewage Treatment Plant, the sludge moisture content is 98.9%, the pH is 6.8, the MLSS is 11.5g / L, the MLVSS is 5.7g / L, and the COD in the sludge supernatant is 40.8mg / L, ammonia nitrogen is 6mg / L, TP is 14mg / L) are injected into two reaction pools A and B respectively through the mud inlet, the sludge in the A reaction pool is subjected to aerobic digestion, and the sludge in the B reaction pool is subjected to ultrasonic-anoxic / good Oxygen digestion. Other experimental conditions are the same as Example 1. After 11 days of digestion, the MLSS removal rate and MLVSS removal rate of the sludge in the B reaction pool were close to those in the A pool, but the total nitrogen removal rate in the B pool was 38.7%, which was higher than that in the A pool, and the sludge supernatant in the B pool The concentration of ammonia nitrogen is also much lower than that of pool A. In addition, the specific resistance of the sludge in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific resistance | aaaaa | aaaaa |

| Moisture content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com