Method for manufacturing paper container and products thereof

A paper container and container technology, which is applied in the field of making paper containers, can solve the problems of long water holding time, insufficient strength, easy deformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

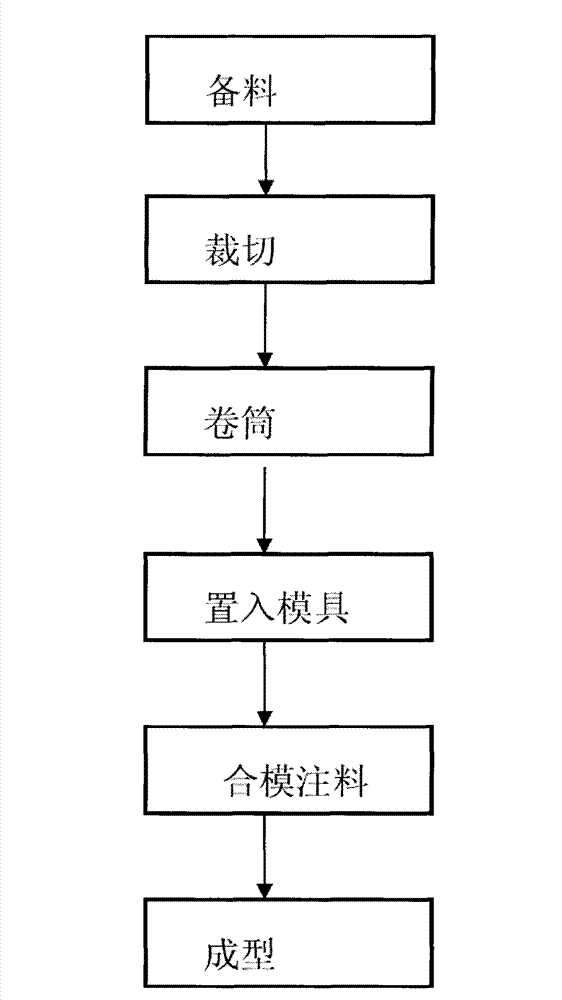

[0040] The present invention relates to a method for making a paper container and its products. The flow chart is described below with reference to the drawings.

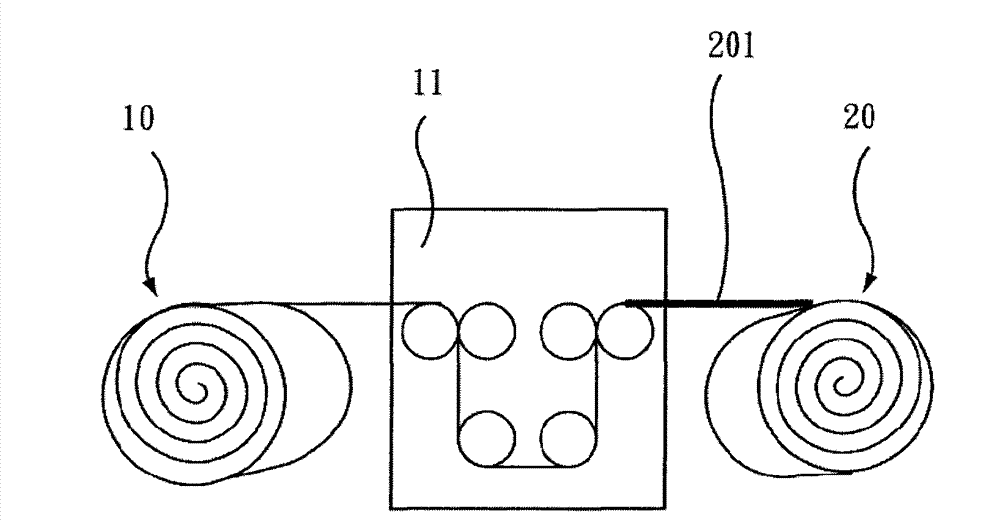

[0041] a. Spare materials: please refer to figure 1 , 2 As shown, in the process of preparing materials, the plain paper roll (10) is passed through the coating machine (11), and the surface of the plain paper roll (10) is covered with a waterproof film (201) to form a coated paper (20), providing the plain paper roll (10) with water resistance through the waterproof membrane (201).

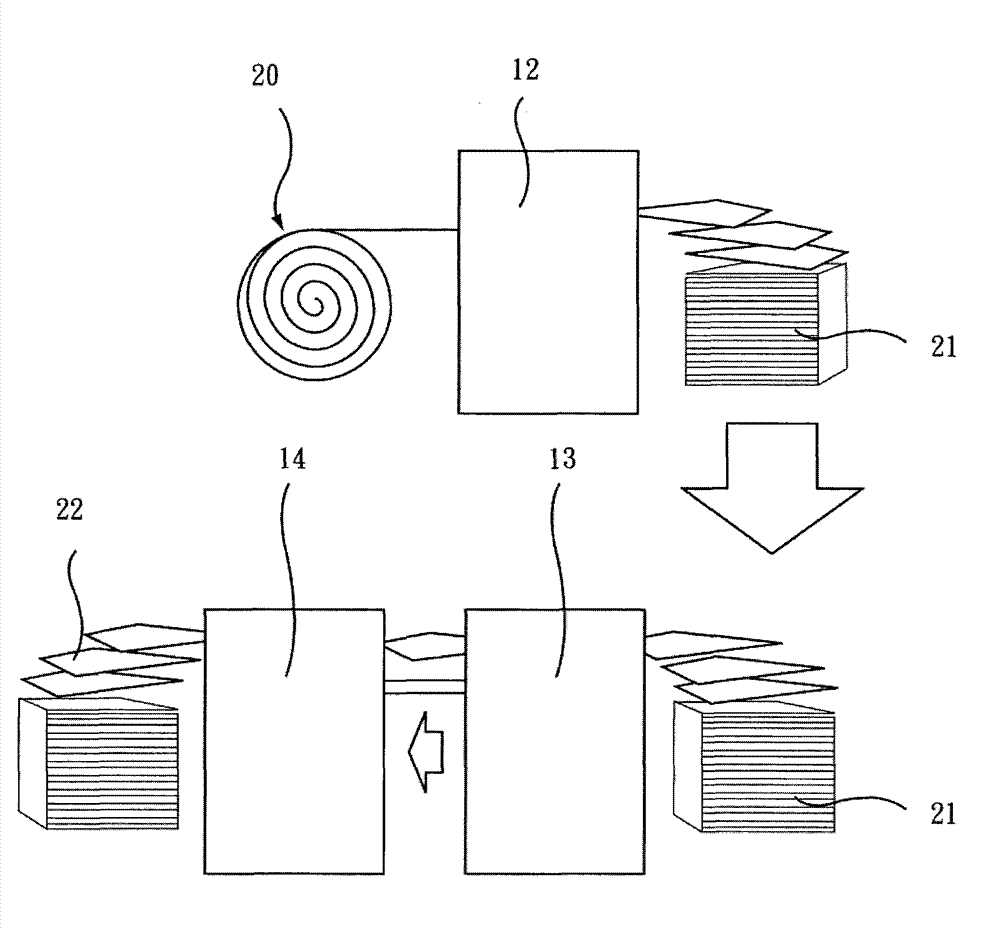

[0042] b. Cutting: please cooperate figure 1 , 3 As shown, the coated paper (20) is automatically cut into the coated paper (21) of the set size by the cutting machine (12), and the coated paper (21) is passed through the printing machine (13) Patterns such as printed pictures, texts or trademarks on the coated paper sheet (21), then enter the die-cutting machine (14) to be cut into the die-cut paper sheet (22) that the container i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com